A synchronous grouting slurry for shield tunnels suitable for water-rich sand layers

A technology of shield tunneling and synchronous grouting is applied in the field of shield tunnel construction building materials, which can solve the problems of easy blockage of grouting pipelines, unsatisfactory application effect, poor settlement control effect, etc., and achieves good water resistance and dispersion. , The effect of good pumpability and easy slurry quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

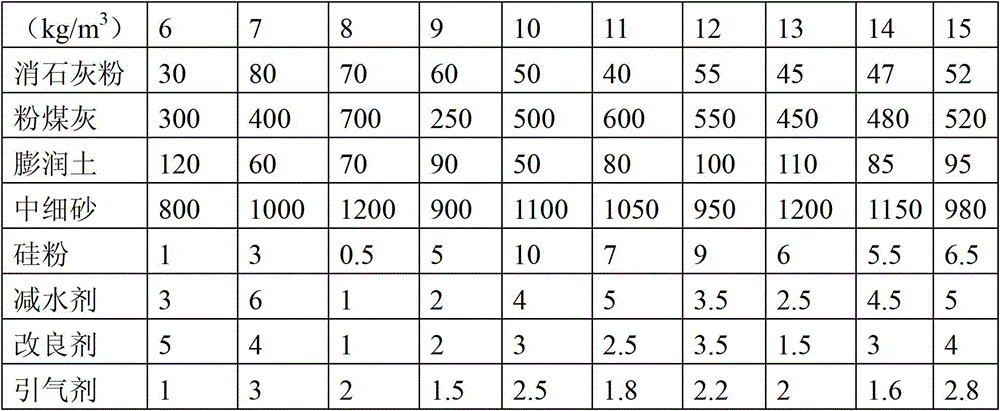

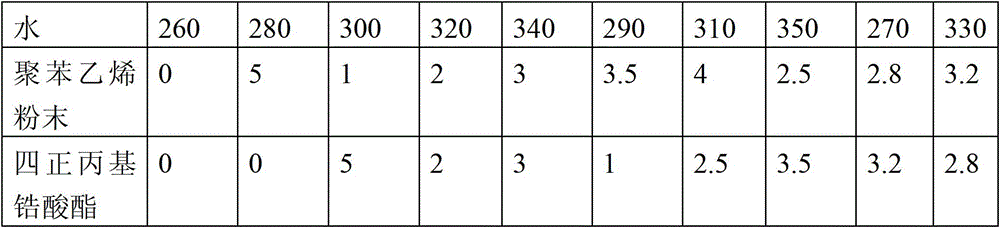

[0038] The weight ratio of each raw material component (kg / m 3 )for:

[0039] Slaked lime 70; fly ash 600; bentonite 60; sand 900; polystyrene powder 1; silicon powder 2; water reducer 4; polyacrylamide 1; gypsum 4; water 330.

[0040] The slurry has a bleeding rate of about 3%, a volume shrinkage rate of 2%, a setting time of 8 to 12 hours, an initial slump of 24 to 26 cm, a slump of not less than 23 cm within 3 hours, and a slump within 8 hours. The fluidity is not less than 19cm, and the fluidity is not less than 230mm within 6 hours.

[0041] The water reducer is a commercially available naphthalene-based water reducer, and the air-entraining agent is sodium dodecylbenzenesulfonate.

Embodiment 2

[0043] The weight ratio of each raw material component (kg / m 3 )for:

[0044] Slaked lime 50; fly ash 500; bentonite 100; sand 1100; polystyrene powder 3; silicon powder 1; water reducer 3; polyacrylamide 1; gypsum 2; air-entraining agent 1; water 310;

[0045] The slurry has a bleeding rate of about 4%, a volume shrinkage rate of about 4%, a setting time of 10 to 14 hours, an initial slump of 24 to 26 cm, a slump of not less than 22 cm within 3 hours, and a flow within 6 hours. The length is not less than 220mm.

[0046] The water reducer is a commercially available naphthalene-based water reducer, and the air-entraining agent is sodium dodecylbenzenesulfonate.

Embodiment 3

[0048] The weight ratio of each raw material component (kg / m 3 )for:

[0049] Slaked lime 35; Fly ash 650; Bentonite 70; Sand 800; Silica fume 1; Water reducer 2; Polyacrylamide 0.5; Gypsum 1; Tetra-n-propyl zirconate 2;

[0050] The slurry has a bleeding rate of about 5%, a volume shrinkage rate of about 3%, a setting time of 12 to 14 hours, an initial slump of 24 to 26 cm, a slump of not less than 23 cm within 3 hours, and a flow within 6 hours. The height is not less than 230mm.

[0051] The water reducer is a commercially available naphthalene-based water reducer, and the air-entraining agent is sodium dodecylbenzenesulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com