Fermentation device for rapidly composting vegetable wastes and using method of fermentation device

A vegetable waste and fermentation device technology, applied in fertilization device, application, preparation of organic fertilizers, etc., can solve problems such as environmental pollution, waste of resources, long fermentation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Description of the construction of the device

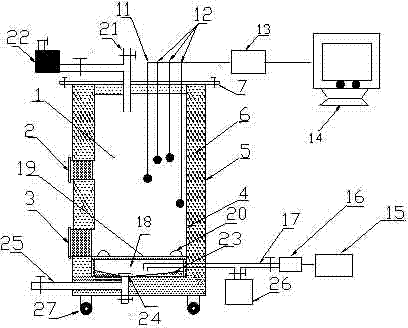

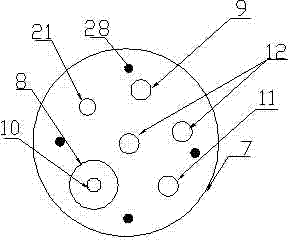

[0066] combine Figure 1-5 Fig., a fermentation device for rapid decomposing of vegetable waste, characterized in that the device is a hollow cylinder, including a fermentation system, a monitoring system, a steam sterilization system, a ventilation system, a leachate system, a heat preservation system, There are 8 major systems of deodorization system and auxiliary tools; the fermentation system is connected with the monitoring system, and the monitoring system reads, stores, manages and prints data through a microcomputer and a printer.

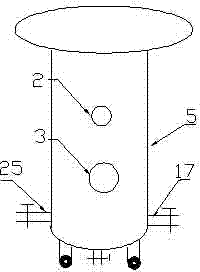

[0067] The fermentation system includes: fermentation chamber 1, sampling port 2, discharge port 3, inner cylinder 4, outer cylinder 5, insulation layer 6, flange sealing insulation cover 7, feeding port 8, observation lamp 9, perspective hole 10, The moving wheel 27, the fixing nut 28, and various holes for other systems;

[0068] The sampling port is opened in the middle of one si...

Embodiment 2

[0083] How to use the device

[0084] 1. Raw material pretreatment

[0085] According to the principles of dry with wet, hard with soft, carbon with nitrogen, etc., mix all kinds of crushed vegetable waste with other auxiliary materials evenly, so that the carbon-nitrogen ratio of the material reaches 25-30:1, and the moisture reaches 55-60%; Among them, vegetable waste refers to various seedlings and tail vegetables produced after vegetable harvesting in vegetable planting and production, such as cucumber seedlings, tomato seedlings, bean seedlings, pepper stalks, eggplant stalks, Chinese cabbage leaves, etc. Other accessories refer to It is chicken manure and mushroom residue; wherein vegetable waste: the ratio of parts by weight of auxiliary materials is 75:25.

[0086] 2. Preparation before loading

[0087] Before charging, some preparations for the fermentation unit are required. First, insert the sealing and insulating plug into the sampling port and the discharge p...

Embodiment 3

[0109] The application effect of the device

[0110] The following is the application test of the fermentation device for rapid decomposing of vegetable waste in improving the degree of decomposing and the number of bacteria, reducing the bacteria and shortening the fermentation time.

[0111] The raw materials are crushed and sun-dried eggplant straws + cucumber seedlings in a weight ratio of 1:3, and the auxiliary materials are chicken manure and mushroom residue in a weight ratio of 1:1. Among them, the weight ratio of vegetable waste: auxiliary material: bacterial strain is 75:25:1, the total water content is 55% to 60%, the volume is 170L, and the room temperature is 21 °C, and four treatments are set.

[0112] Treatment 1: Carry out temperature-controlled and pressure-controlled aerobic fermentation in the inventive device; Treatment 2: Carry out temperature-controlled aerobic fermentation in the inventive device; Treatment 3: Perform natural (uncontrolled temperature-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com