Energy saving method for butadiene preparation by butylene oxydehydrogenation

A technology for oxidative dehydrogenation and butadiene, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc. The effect of obvious technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

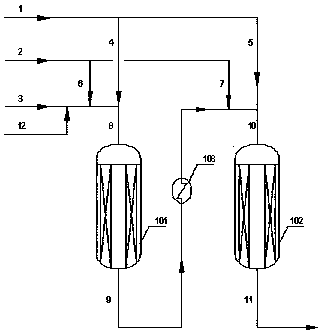

[0033] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology, the reactor is two-stage, and the two-stage reactor is an adiabatic radial fixed-bed reactor, using 36000 kg / h N 2 Mixed gas with 20,000 kg / h of water vapor is used as the diluent, the total amount of raw material butene is 19,670 kg / h, and the total amount of oxygen is 7,560 kg / h. The butene raw material is divided into two parts. Alkene: Oxygen: diluent molar ratio is 1:0.52:14. After mixing with oxygen and diluent, it enters the first-stage oxidative dehydrogenation reactor at a temperature of 320°C and a pressure of 0.12MPaG. The outlet gas temperature is 490°C. After heat exchange by the heat exchanger, it is mixed with the second-stage butene and the second-stage air to enter the secondary reactor. The flow rate of the second-stage butene is 10270 kg / h. The secondary reactor inlet butene: oxygen: The diluent molar ratio is 1:0.65:14, the reaction temper...

Embodiment 2

[0037] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology, the reactor is three-stage, and the three-stage reactors are all adiabatic radial fixed-bed reactors, using 72000 kg / h CO 2 As a diluent, the total amount of raw material butene is 18920kg / h, the total amount of air is 36000 kg / h, the butene raw material is divided into three parts, the flow rate of butene in the first stage is 9200 kg / h, according to the molar ratio of butene: oxygen: diluent is 1 : 0.5:10 ratio with air, CO 2 After mixing, it enters the first-stage oxidative dehydrogenation reactor at a temperature of 320°C and a pressure of 0.12MPaG. The outlet gas temperature of the first-stage reactor is 485°C. The first-stage air is mixed into the secondary reactor, the second-stage butene flow rate is 4800 kg / h, the secondary reactor inlet butene: oxygen: water molar ratio is 1:0.6:10, the reaction temperature is 330°C, and the pressure is 0.11MPaG. T...

Embodiment 3

[0041] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology, the reactor is two-stage, and the two-stage reactor is an adiabatic axial fixed-bed reactor, using 44000 kg / h CO 2 The mixed gas with 9000 kg / h water vapor is the diluent, the total amount of butene as raw material is 19670 kg / h, the total amount of air is 38500 kg / h, the butene raw material is divided into two parts, and the flow rate of butene in the first stage is 9400 kg / h The molar ratio of alkene:oxygen:diluent is 1:0.52:9. After mixing with air and diluent, it enters the first-stage oxidative dehydrogenation reactor at a temperature of 320°C and a pressure of 0.12MPaG. The outlet gas temperature is 500°C. After heat exchange by the heat exchanger, it is mixed with the second-stage butene and the second-stage air and enters the secondary reactor. The flow rate of the second-stage butene is 10270 kg / h. The inlet butene of the secondary reactor: oxygen: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com