Zirconium metal coordination polymer and synthesis method thereof and application thereof for catalyzing ethylene polymerization

A metal coordination and polymer technology, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problem of low activity, achieve high catalytic activity, convenient preparation, and low dosage low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of porous zirconium metal coordination polymer Zr-1

[0030]

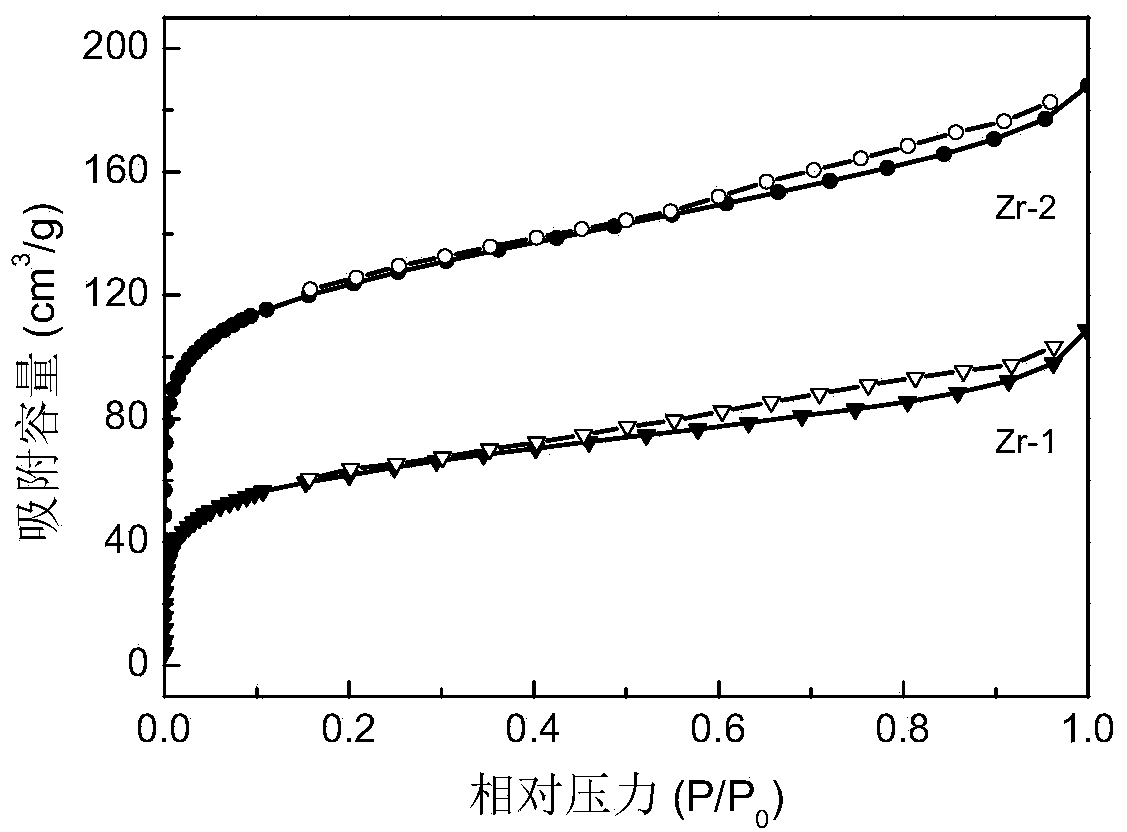

[0031] Weigh 10.18g (0.22mmol) of ligand L and dissolve it in 10mL dry tetrahydrofuran solution under nitrogen, add 16.0mg (0.66mmol) sodium hydride and stir for 12 hours; add ZrCl to the reaction flask 4 (THF) 2 125 mg (0.33 mmol), refluxed for 3 days, the obtained yellow precipitate was washed with dry tetrahydrofuran, dichloromethane, and toluene, and then dried under vacuum at 120°C for 12 hours to obtain 0.21 g of yellow solid powder with a yield of about 75%. The composition of elemental analysis is: C56.57, H4.72, N3.28. The Zr content measured by ICP was 10.0%. The specific surface area of Zr-1 measured by the specific surface area analyzer is 230m 2 / g. The single-point adsorption total pore volume of Zr-1 measured by the specific surface area analyzer is 0.17cm 3 / g, the total pore volume of micropores is 0.087cm 3 / g.

Embodiment 2

[0032] Embodiment 2: Preparation of porous zirconium metal coordination polymer Zr-2

[0033]

[0034] Weigh 20.19g (0.22mmol) of ligand L and dissolve it in 10mL dry tetrahydrofuran solution under nitrogen, add 16.0mg (0.66mmol) sodium hydride and stir for 12 hours; add ZrCl to the reaction flask 4 (THF) 2 125 mg (0.33 mmol), refluxed for 3 days, the obtained pale yellow precipitate was washed with dry tetrahydrofuran, dichloromethane and toluene, and then dried under vacuum at 120°C for 12 hours to obtain 0.24 g of yellow solid powder with a yield of about 85%. The composition of elemental analysis is: C55.55, H6.05, N3.29. The Zr content measured by ICP was 10.6%. The specific surface area of Zr-2 measured by the specific surface area analyzer is 479m 2 / g. The single-point adsorption total pore volume of Zr-2 measured by the specific surface area analyzer is 0.31cm 3 / g, the total pore volume of micropores is 0.186cm 3 / g.

Embodiment 3

[0035] Embodiment 3: Preparation of porous zirconium metal coordination polymer Zr-3

[0036]

[0037] Weigh 30.20 g (0.22 mmol) of ligand L and dissolve it in 10 mL of dry tetrahydrofuran solution under nitrogen, add 16.0 mg (0.66 mmol) of sodium hydride and stir for 12 hours; add ZrCl to the reaction flask 4 (THF) 2 125 mg (0.33 mmol), refluxed for 3 days, the obtained yellow precipitate was washed with dry tetrahydrofuran, dichloromethane, and toluene, and then dried under vacuum at 120°C for 12 hours to obtain 0.19 g of yellow solid powder with a yield of about 68%. The composition of elemental analysis is: C54.64, H6.70, N3.72. The Zr content measured by ICP was 10.2%. The specific surface area of Zr-3 measured by the specific surface area analyzer is 85m 2 / g. The single-point adsorption total pore volume of Zr-3 measured by the specific surface area analyzer is 0.13cm 3 / g, the total pore volume of micropores is 0.034cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com