Poly (propylene carbonate) (PPC) production process

A polypropylene carbonate and polymerization technology, which is applied in the fields of polymer synthesis and chemical industry, can solve the problems of limited popularization and use, high price of PPC, etc., and achieve the effects of less investment in equipment, wide molecular weight distribution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

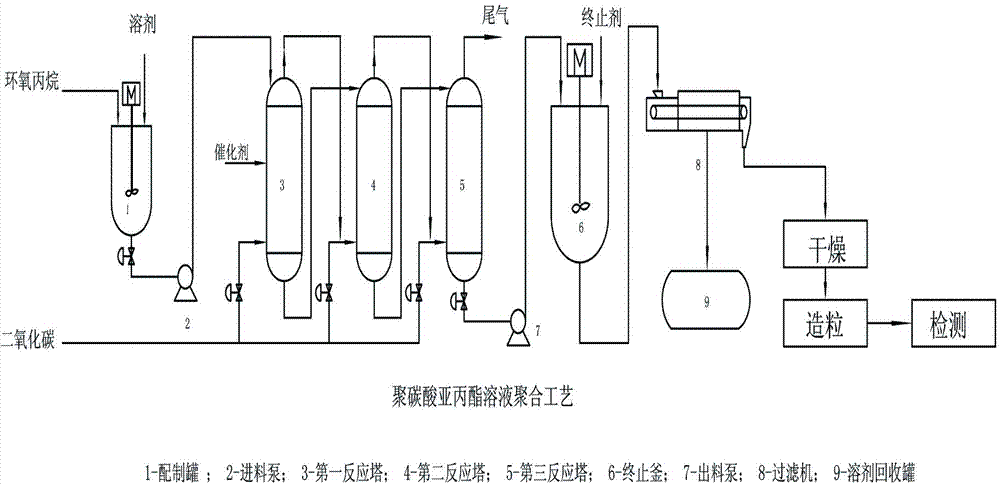

[0016] The process flow of the present invention is as follows: put the refined propylene oxide and solvent into the configuration tank 1 with agitator, and pump into the first reaction tower 3 (plate type) through the feed pump 2, and the CO 2 Compressed air is pumped into the reaction tower, CO 2 After contacting with propylene oxide, the PPC long-chain polymer is obtained by reaction. Keep the proper solution viscosity, pump the reaction product into the second reaction tower 4 (plate type), after the reaction, pump into the third reaction tower 5 (bubble reaction tower), after a certain period of reaction, use the reaction product with a discharge pump 7 Pump into the termination tank 6, a small amount of unreacted CO 2 No recycling value, non-toxic, and can be discharged directly. In the termination tank 6, the anionic polymerization reaction of PPC is terminated with a proton-containing terminator to obtain a PPC slurry with a suitable viscosity. The slurry contains PPC, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com