Preparation method and application of secondary modified layered double hydroxide

A hydroxide and secondary modification technology, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, etc., can solve the problems of difficult delamination, difficult compatibility of polymers, high charge density of sheets, and achieve large layers. Effects of distance, reduced combustion performance, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, cobalt chloride and aluminum chloride were used as reactants, and sodium laurate was used as modifier to prepare a primary modified cobalt-aluminum layered double hydroxide by co-precipitation method. The specific modification process is as follows:

[0041] Prepare an aqueous solution in which 4.44g of sodium laurate is dissolved in advance, and 4.76g of CoCl 2 ·6H 2 O and 2.415g AlCl 3 ·9H 2 O metal salt mixed solution in N 2 It was added dropwise into the vigorously stirred sodium laurate aqueous solution under the atmosphere, during which the co-precipitation reaction temperature of the system was kept at 40°C, and the NaOH solution was continuously added to maintain the pH between 9.0-10.0. The resulting suspension was then placed in N 2 Under the protection of 70 ℃ crystallization 24h. The resulting solid product was washed with boiled deionized water and filtered until the pH of the filtrate was neutral, and the fi...

Embodiment 2

[0043] The primary modified cobalt-aluminum layered double hydroxide obtained in Example 1 is subjected to secondary modification, and dodecyltrimethylammonium bromide is selected as the secondary modifier. The specific modification process is as follows:

[0044] (1) Mix 50ml of ethanol with 50ml of water to prepare ethanol aqueous solution;

[0045] (2) Add 1.5 g of the primary modified cobalt-aluminum layered double hydroxide prepared in Example 1 to the above-mentioned aqueous ethanol solution, and then add 1.82 g of the secondary modifier dodecyltrimethylammonium bromide , stirred to form a mixed solution;

[0046] (3) Heat up the mixed solution obtained in step (2) to 70°C, stir, and react for 24 hours;

[0047] (4) Reflux, crystallize, and filter the reaction solution obtained after the reaction in step (3), and then wash and dry the obtained solid product to obtain red secondary modified cobalt-aluminum layered double hydroxide.

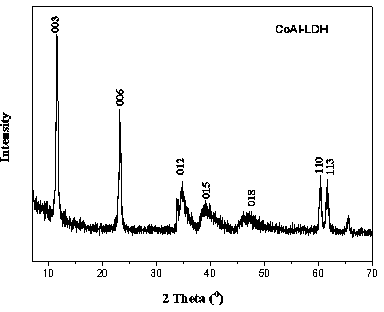

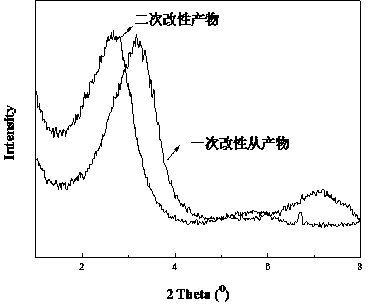

[0048] As can be seen fr...

Embodiment 3

[0051] In the reaction kettle equipped with a stirring and reflux device, add 50ml of deionized water and 50ml of ethanol, after stirring evenly, add 5g of the primary modified CoAl-LDH prepared in Example 1 and 7g of the secondary modifier Tetradecyl Trimethylammonium bromide, heated to 60°C with stirring, reflux crystallization reaction for 12 hours, then lowered the reaction kettle to room temperature, filtered, washed, and dried the filter cake at 60°C to obtain the red powder product secondary Modified CoAl-LDH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com