Novel macromolecule emulsifier for cosmetics and preparation method thereof

A polymer emulsifier, cosmetic technology, applied in cosmetic preparations, cosmetics, cosmetic preparations and other directions, can solve the problems of difficult dispersion of powder, limited use range, easy jelly and other problems, and achieves increased hydrodynamic volume, Good suspension stability, enhance the effect of thickening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

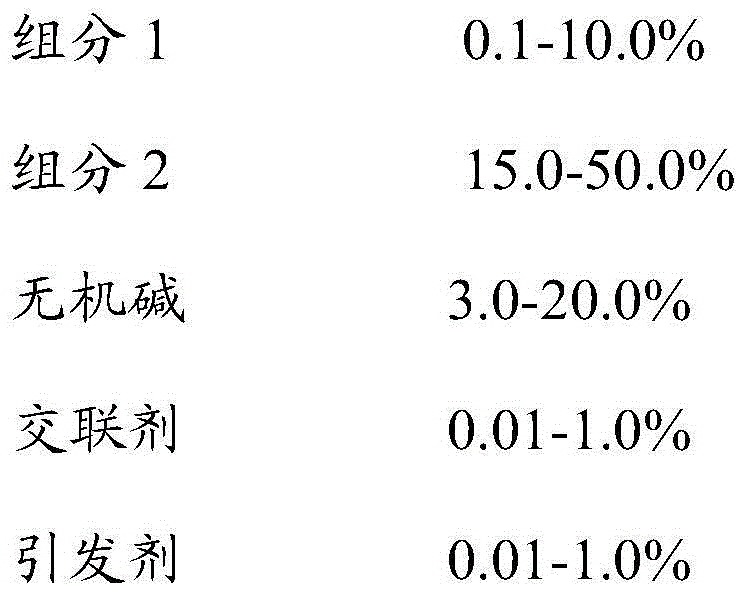

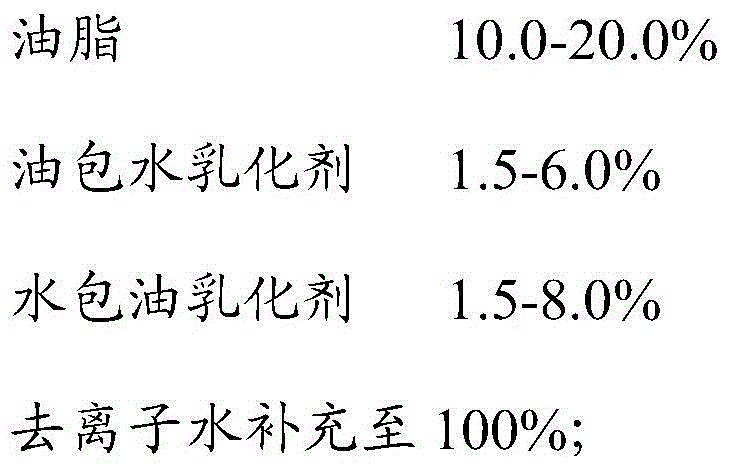

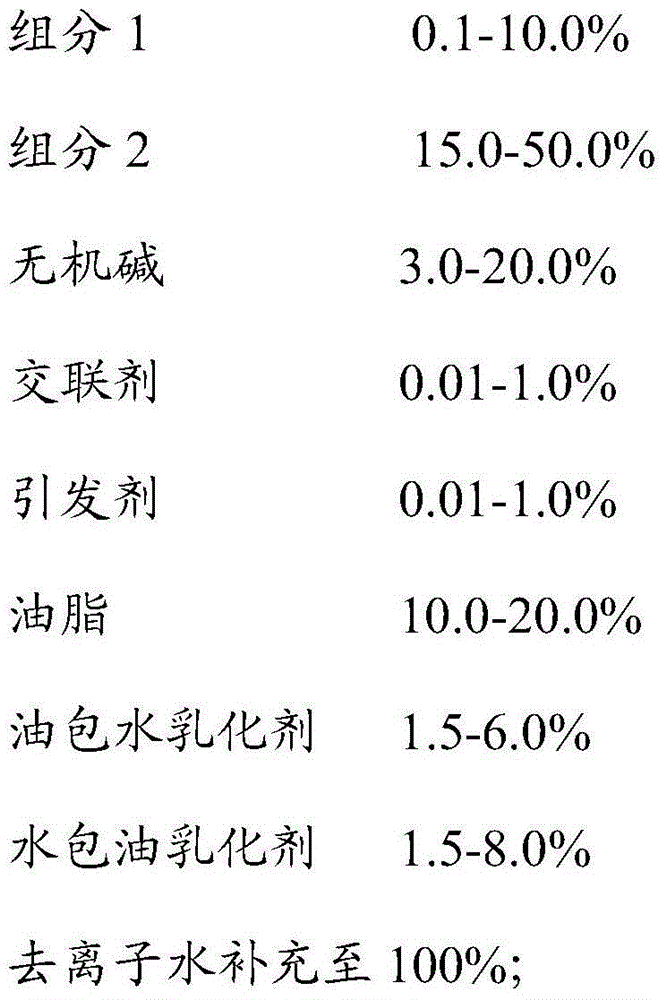

[0032] The weight percentage of each component in the following table 1 carries out the preparation of novel cosmetic polymer emulsifier.

[0033] Table 1. The distribution ratio of each component of the new polymer emulsifier for cosmetics (total amount 100kg)

[0034] serial number

raw material name

wt%

01

Acryloyldimethyltaurine

21.5

02

10 # Cosmetic grade white mineral oil

13.0

03

2.0

04

glyceryl monooleate

2.5

05

behenyl acrylate

3.5

06

350cs simethicone oil

2.0

07

PEG-20 Sorbitan Monostearate

3.0

08

4.2

09

0.15

10

Polyethylene glycol (1000) diacrylate

0.08

11

Deionized water

add up to 100

[0035] making process:

[0036] (1) Under continuous stirring, add deionized water, sodium hydroxide and acryloyl dimethyl taurine into t...

Embodiment 2

[0044] The weight percentage of each component in the following table 2 carries out the preparation of novel cosmetic polymer emulsifier.

[0045] Table 2. The distribution ratio of each component of the new polymer emulsifier for cosmetics (total amount 100kg)

[0046] serial number

raw material name

wt%

01

Acryloyldimethyltaurine

27.5

02

10.0

03

Tripolyglyceryl distearate

2.5

04

glyceryl monooleate

2.5

05

cetyl methacrylate

5.5

06

8.0

07

PEG-20 Methyl Glucoside Sesquioleate

3.0

08

7.5

09

0.15

10

0.12

11

Deionized water

add up to 100

[0047] making process:

[0048](1) Under continuous stirring, add deionized water, potassium hydroxide and acryloyl dimethyl taurine into the reaction kettle and mix evenly, ...

Embodiment 3

[0056] The weight percentage of each component in the following table 3 carries out the preparation of novel cosmetic polymer emulsifier.

[0057] Table 3. The distribution ratio of each component of the new polymer emulsifier for cosmetics (total amount 100kg)

[0058] serial number

raw material name

wt%

01

Acryloyldimethyltaurine

34.5

02

Synthetic squalane

13.0

03

Sorbitan Monostearate

2.5

04

Sorbitan sesquiisostearate

2.5

05

stearyl acrylate

4.0

06

PEG-20 Sorbitan Monooleate

3.0

07

Potassium hydroxide

9.5

08

Azobisisobutylamidine hydrochloride

0.10

09

0.08

10

Deionized water

add up to 100

[0059] making process:

[0060] (1) Under continuous stirring, add appropriate amount of deionized water, potassium hydroxide and acryloyl dimethyl taurine into the reaction kettle and mix even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com