A particle-added low-silver-based lead-free solder

A lead-free solder and lead-free solder technology, applied in the field of Co nano hollow sphere particle reinforced low silver lead-free solder and nano particle reinforced lead-free solder, can solve the problem of poor wettability, decreased joint life, welding Problems such as reduced reliability of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of Co nano hollow spheres

[0022] (1) Iron core preparation:

[0023] a. Take 69.5g FeSO 4 ·7H 2 O, with 0.5mol / L solution 500mL;

[0024] b. Add 50mL deionized water to 150mL ammonia water for later use, weigh 4.5gNaBH 4 Add the above standby ammonia water;

[0025] c. Under mechanical stirring, the above two are mixed and heated to 80°C. After about 15 minutes, there is a bright silver mirror on the cup wall, the bubbles disappear, the reaction is over, and the iron core is formed.

[0026] (2) Coated Co:

[0027] a. Take 21g CoSO 4 and potassium sodium tartrate, 10gNaOH, respectively take a certain amount of distilled water to dissolve, and then mix to form a solution with a complexation ratio of 1:1 with a pH>13, use a volumetric flask to make up 1L, and take 500mL;

[0028] b. Take the iron core of the above step and add 500mL of plating solution, take 10mL of hydrazine hydrate and dilute to 40mL, gradually add to start the reaction, stir ult...

Embodiment 2

[0042] The low-silver-based lead-free solder added to the Co nano-hollow sphere particles in this embodiment is composed of low-silver-based tin-based solder and Co nano-hollow sphere particles, wherein the diameter of the Co nano-hollow sphere particles is about 600 nm. The lead-free solder composition is:

[0043]

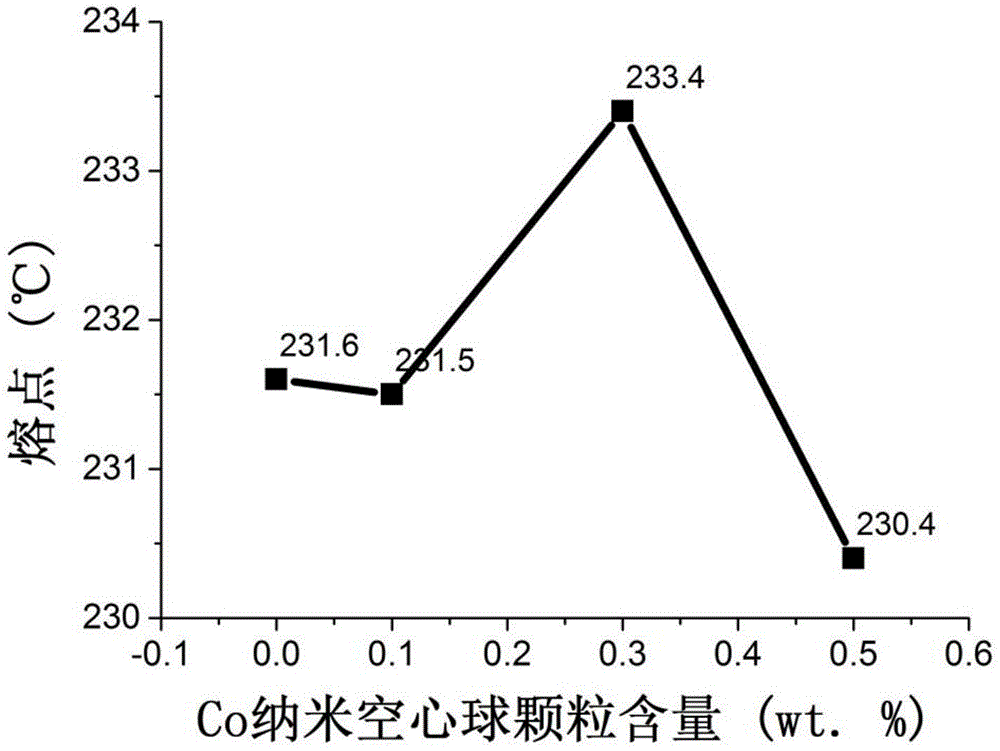

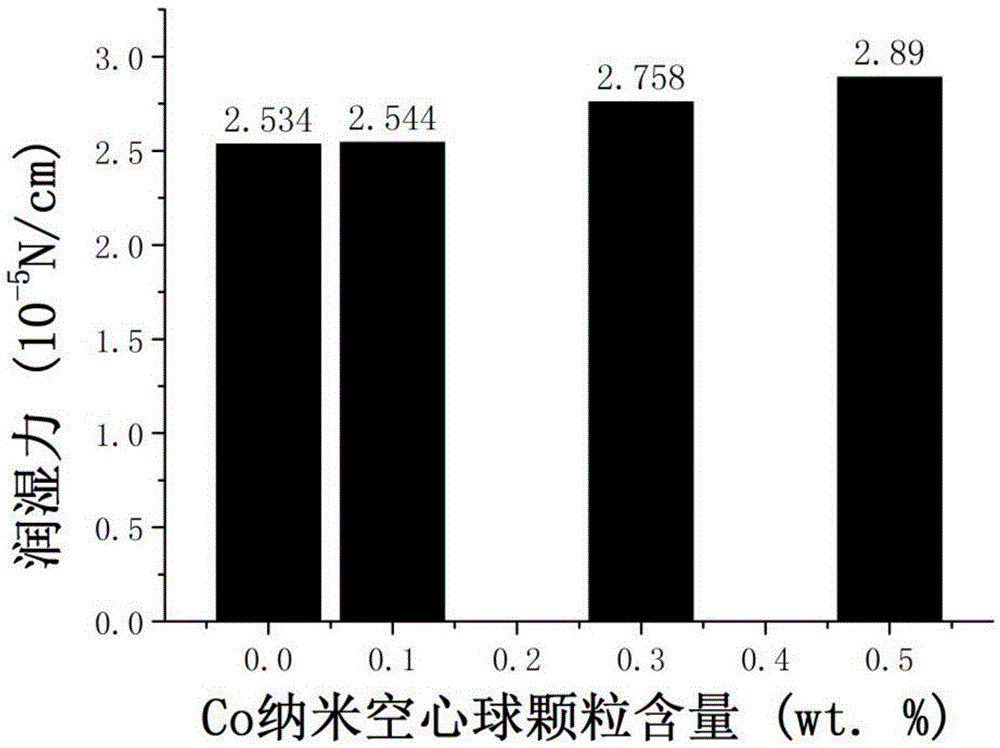

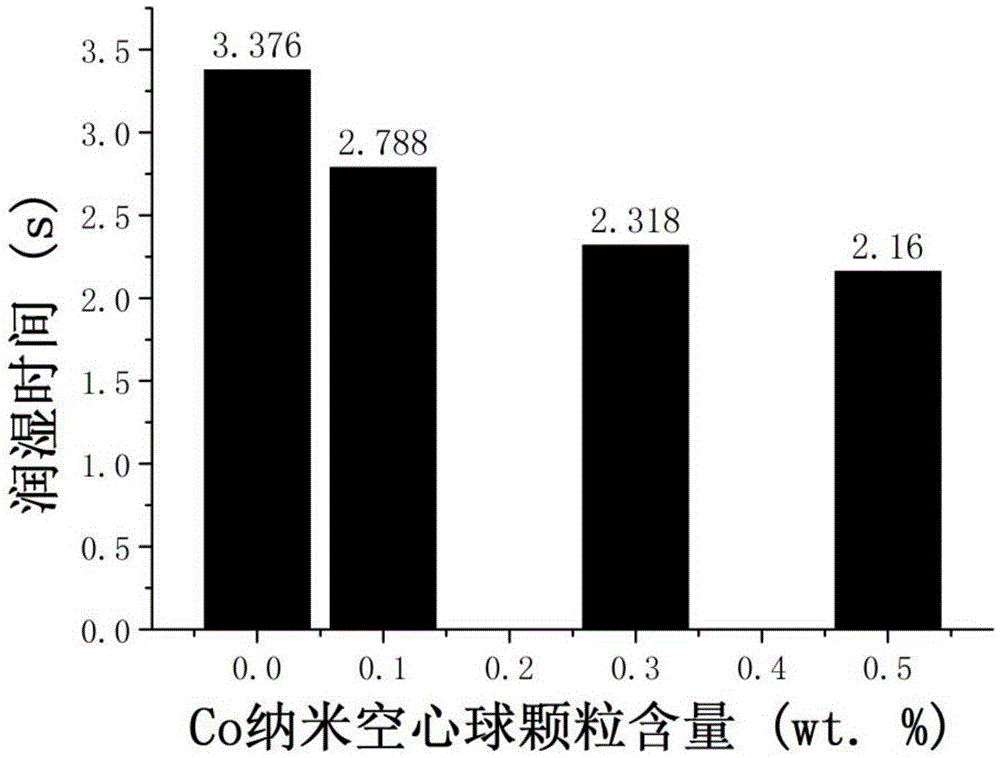

[0044] The prepared solder of this composition was tested for wetting force, DSC test, and observation of intermetallic compounds at the interface. The results are as follows: figure 2 , 3 , 4, and 6 show that all kinds of performance have been significantly improved.

[0045] [1] Shangguan Dongkai. Environmental protection strategy guides the electronics manufacturing industry to go lead-free [A]. See: Proceedings of the 14th Shanghai International SMT Technology Advanced Symposium [C], Shanghai, 2004, 14-22

[0046] [2] Roadmap IPC. A guide for assembly of lead-free electronics [J]. Draft IV, June, 2000.

[0047][3] ZhangL, HeC, GuoY, et al.Developmentof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com