Method for synthesizing flower-ball-shaped bismuth phosphate nano-powder photocatalyst by microwave hydrothermal process

A bismuth phosphate nanometer, microwave hydrothermal method, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of low solar energy utilization, restricting the practical application of photocatalytic technology, and low quantum efficiency. , to achieve the effect of being conducive to large-scale promotion, novel appearance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

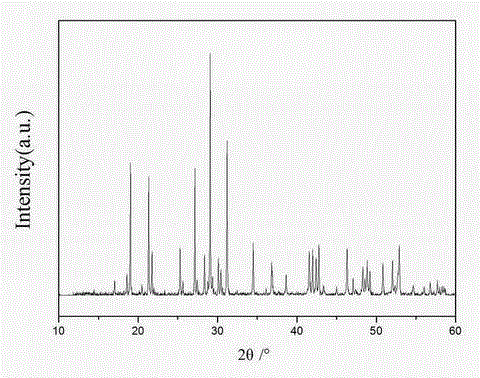

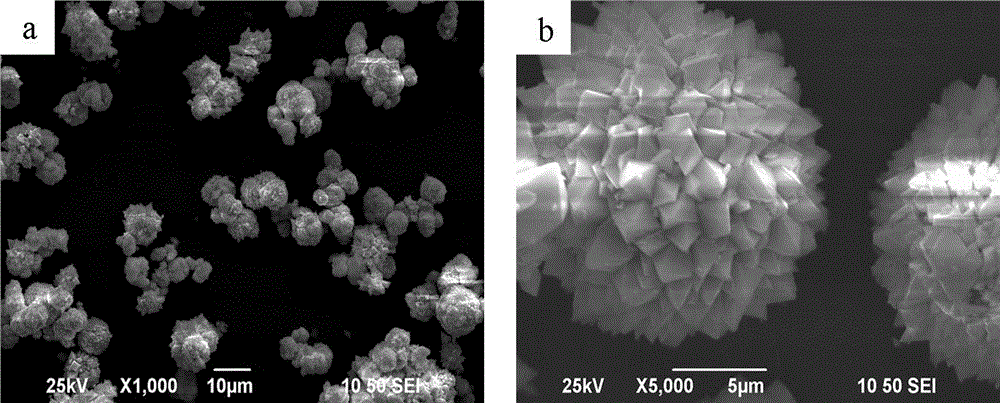

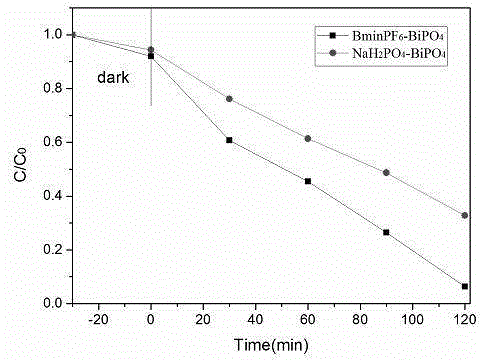

[0011] (1) Under the condition of magnetic stirring, dissolve 0.002mol of bismuth nitrate in 30mL of deionized water, and stir for 20min to obtain solution A; (2), under the condition of magnetic stirring, dissolve 0.002mol of BmimPF 6 Add dropwise to solution A, and continue to stir for 30 minutes after the dropwise addition to obtain the precursor solution; (3), transfer the above precursor solution to a microwave hydrothermal reactor lined with polytetrafluoroethylene, and adjust the pH with nitric acid =1, the hydrothermal temperature is 180°C, microwave hydrothermal for 60min; (4), after the reaction is completed, cool to room temperature, use deionized water and absolute ethanol to wash repeatedly by centrifugation, and vacuum dry at 80°C for 12h to obtain the white target product. figure 1 Show that the powder prepared in this example is a pure phase of BiPO 4 structure, no impurity peaks appear, sharp diffraction peaks indicate good crystallinity, figure 2 It shows t...

Embodiment 2

[0013] (1) Under the condition of magnetic stirring, dissolve 0.002mol of bismuth nitrate in 30mL of deionized water, and stir for 20min to obtain solution A; (2), under the condition of magnetic stirring, dissolve 0.002mol of BmimPF 6 Add dropwise to solution A, and continue to stir for 30 minutes after the dropwise addition to obtain the precursor solution; (3), transfer the above precursor solution to a microwave hydrothermal reactor lined with polytetrafluoroethylene, and adjust the pH with nitric acid =4, the hydrothermal temperature is 200°C, microwave hydrothermal for 40min; (4), after the reaction is completed, cool to room temperature, use deionized water and absolute ethanol to wash repeatedly by centrifugation, and vacuum dry at 80°C for 12h to obtain the white target product.

Embodiment 3

[0015] (1) Under the condition of magnetic stirring, dissolve 0.002mol of bismuth nitrate in 30mL of deionized water, and stir for 20min to obtain solution A; (2), under the condition of magnetic stirring, dissolve 0.002mol of BmimPF 6 Add dropwise to solution A, and continue to stir for 30 minutes after the dropwise addition to obtain the precursor solution; (3), transfer the above precursor solution to a microwave hydrothermal reactor lined with polytetrafluoroethylene, and adjust the pH with ammonia water =8, the hydrothermal temperature is 220°C, microwave hydroheating for 20min; (4), after the reaction is completed, cool to room temperature, use deionized water and absolute ethanol to wash repeatedly by centrifugation, and vacuum dry at 80°C for 12h to obtain the white target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com