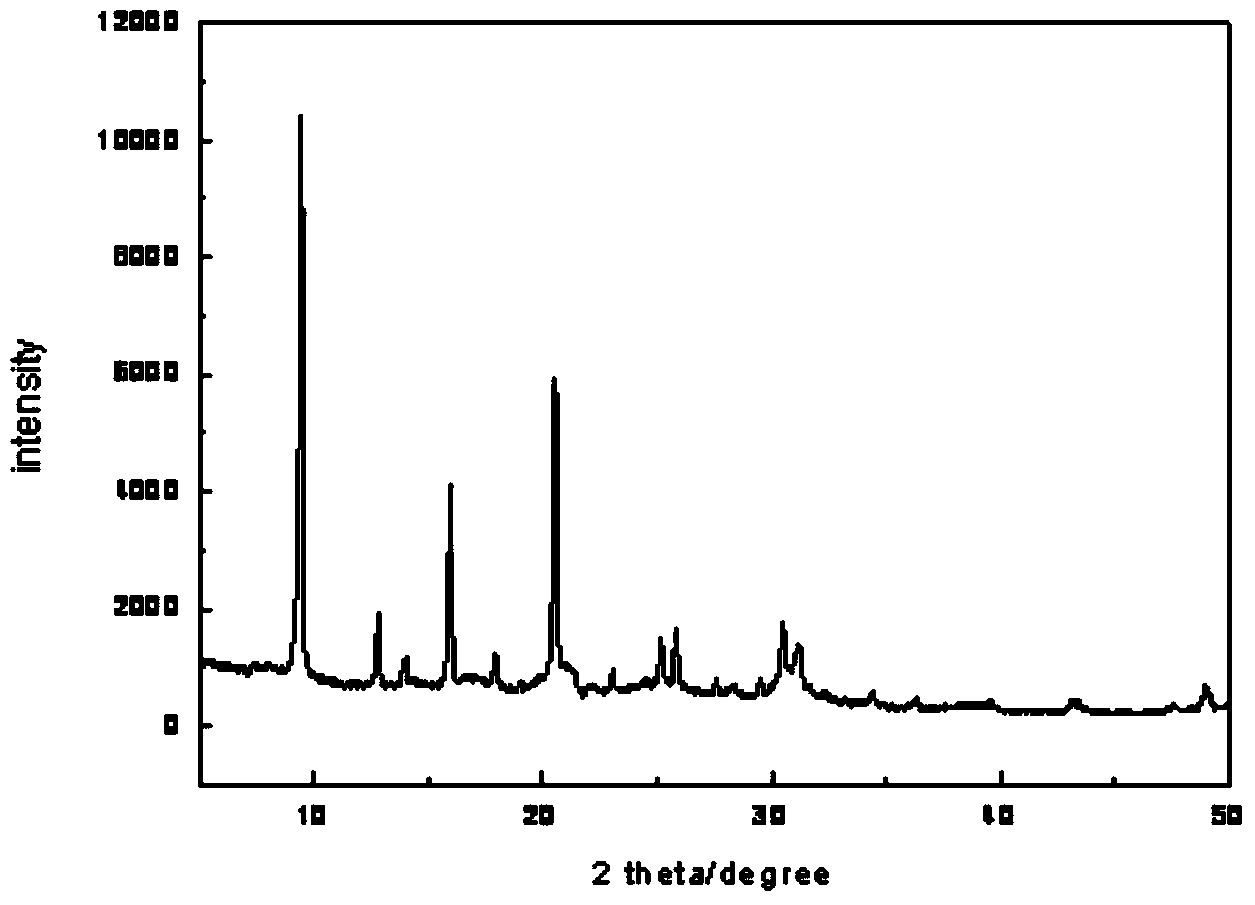

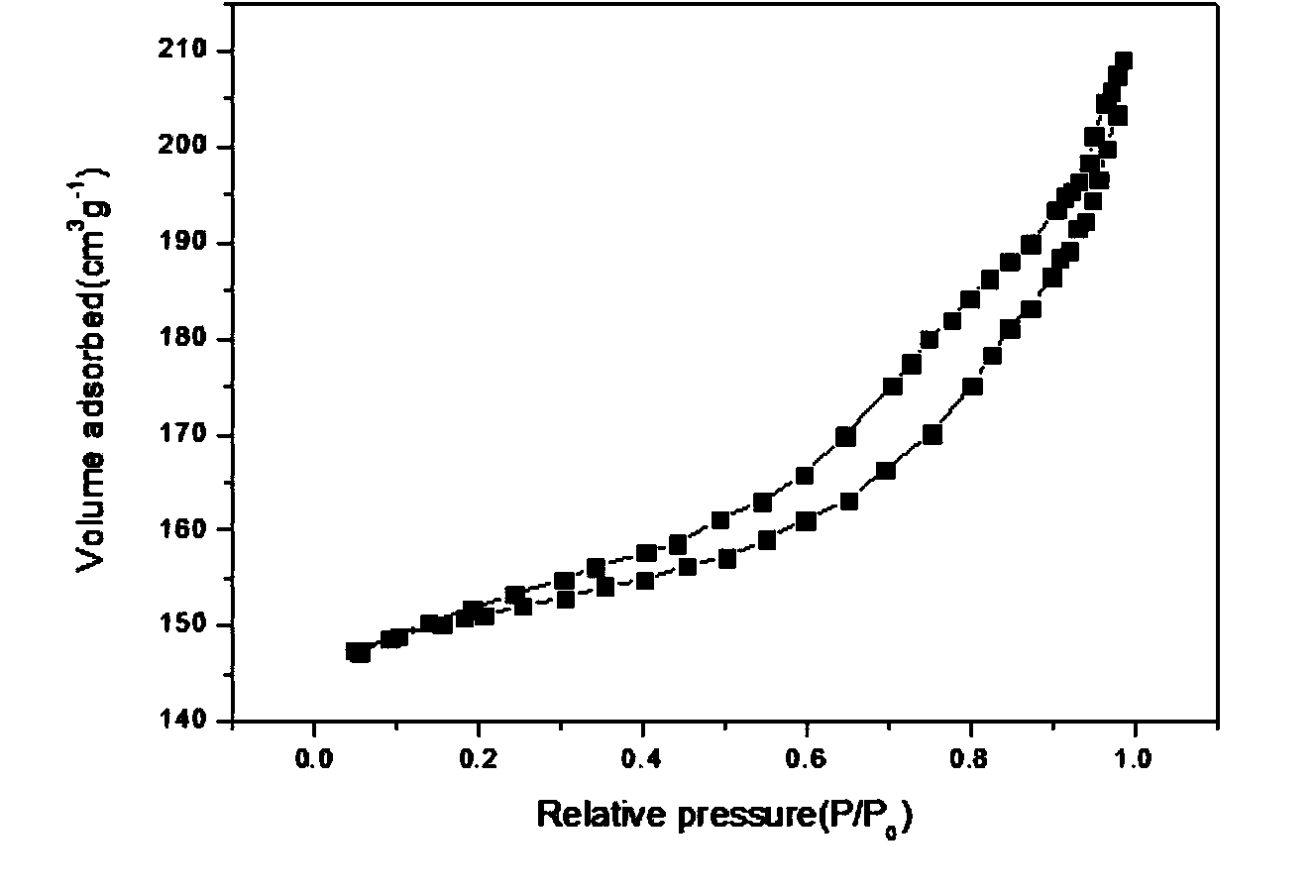

Preparation method of silicoaluminophosphate molecular sieve with hierarchical pore structure

A technology of silicoaluminophosphate and molecular sieve, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of difficulty in industrialization, reducing the acid performance of the catalyst, and high cost of the template agent, and achieves an increase in the availability of acid sites. portability, easy to realize industrialization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the silicoaluminophosphate molecular sieve with hierarchical porous structure in this embodiment comprises the following steps:

[0029] Step 1. Add 75g of silica sol, 150g of pseudoboehmite, 270g of orthophosphoric acid and 270g of triethylamine into 1000mL of deionized water, mix and stir evenly to form a primary gel mixture, and then place the primary gel mixture in a crystallization kettle , heat preservation at 220° C. for 18 hours to carry out hydrothermal crystallization treatment, and centrifuge to take the supernatant after natural cooling; the mass percentage of silicon dioxide in the silica sol is 25%;

[0030] Step 2, add silica sol, pseudo-boehmite, orthophosphoric acid and triethylamine to the supernatant described in step 1, mix and stir evenly to form a secondary gel mixture, and then place the secondary gel mixture in a crystal In the kettle, heat preservation at 200°C for 24 hours to carry out hydrothermal crystallization trea...

Embodiment 2

[0034] The preparation method of the silicoaluminophosphate molecular sieve with hierarchical porous structure in this embodiment comprises the following steps:

[0035] Step 1. Add 20g of ethyl orthosilicate, 200g of aluminum isopropoxide, 250g of orthophosphoric acid and 250g of tetraethylammonium bromide into 1000mL of deionized water, mix and stir evenly to form a primary gel mixture, and then place the primary gel mixture in In the crystallization kettle, heat preservation at 170°C for 30 hours for hydrothermal crystallization treatment, and centrifuge to take the supernatant after natural cooling;

[0036] Step 2. Add ethyl orthosilicate, aluminum isopropoxide, orthophosphoric acid and tetraethylammonium bromide to the supernatant described in step 1, mix and stir evenly to form a secondary gel mixture, and then add the secondary gel The rubber mixture was placed in a crystallization kettle, kept at 220°C for 18 hours for hydrothermal crystallization treatment, and filte...

Embodiment 3

[0040] The preparation method of the silicoaluminophosphate molecular sieve with hierarchical porous structure in this embodiment comprises the following steps:

[0041] Step 1. Add 60g ethyl orthosilicate, 100g pseudoboehmite, 170g orthophosphoric acid and 190g tetraethylammonium hydroxide into 1000mL deionized water, mix and stir evenly to form a primary gel mixture, and then put the primary gel mixture Place in a crystallization kettle, hydrothermally crystallize at 200°C for 25 hours, centrifuge after natural cooling, and take the supernatant;

[0042] Step 2. Add ethyl orthosilicate, pseudoboehmite, orthophosphoric acid and tetraethylammonium hydroxide to the supernatant described in step 1, mix and stir evenly to form a secondary gel mixture, and then add the secondary The gel mixture is placed in a crystallization kettle, kept at 180°C for 26 hours for hydrothermal crystallization treatment, filtered after natural cooling to obtain a filter cake and filtrate; the ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com