Coking wastewater pretreatment method and coking wastewater pretreatment system

A technology for coking wastewater and pretreatment, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of high capital construction cost and operating cost of physical method, and large influence of biochemical method on water volume. , difficult to meet the standard stably, to achieve the effect of reducing energy consumption, improving economy, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

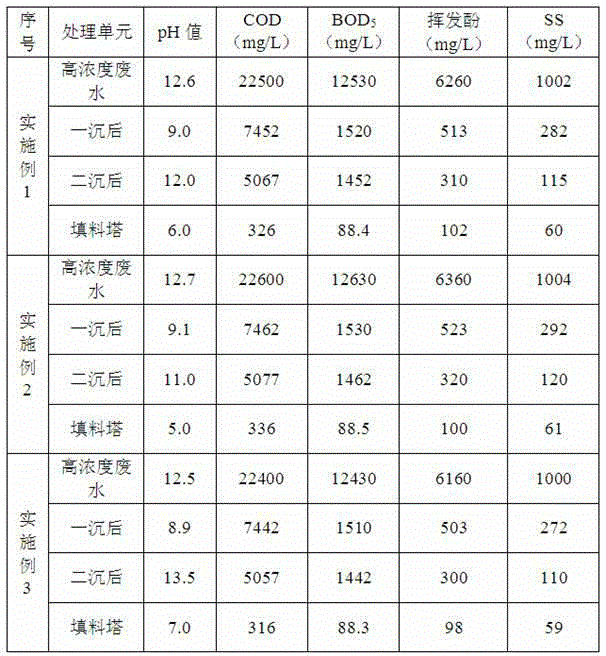

Embodiment 1

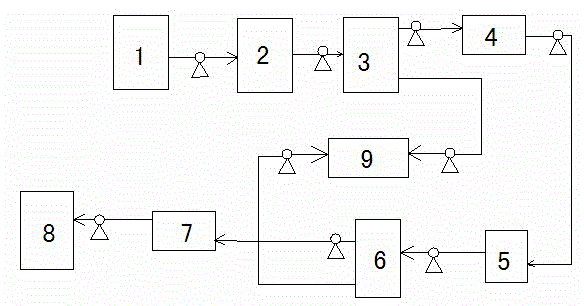

[0017] Such as figure 1 As shown, the coking wastewater pretreatment system includes a sump 1, a first regulating pond 2, a first sedimentation pond 3, an oxidation pond 4, a second regulating pond 5, a second Pool 7 and packed tower 8. Both the first sedimentation tank 3 and the second sedimentation tank 6 are connected with a sludge tank 9 through a pump.

[0018] The coking wastewater pretreatment method includes the following steps: (1) The coking wastewater passing through the grid enters the sump 1 with a total volume of 20 cubic meters. The wastewater enters the first regulating tank 2 through a pump, and 200 L of sulfurous acid with a concentration of 30 g / L is added. Iron solution, aerated and stirred for 10 minutes; (2) enter the first sedimentation tank 3 through the pump, and stir while adding cationic polyacrylamide (50 ionicity) with a molecular weight of 12 million until the mud and water in the first sedimentation tank 3 Stratification; (3) pump the solution ...

Embodiment 2

[0020] Such as figure 1 As shown, the coking wastewater pretreatment system includes a sump 1, a first regulating pond 2, a first sedimentation pond 3, an oxidation pond 4, a second regulating pond 5, a second Pool 7 and packed tower 8. Both the first sedimentation tank 3 and the second sedimentation tank 6 are connected with a sludge tank 9 through a pump.

[0021] Coking wastewater pretreatment method: (1) The coking wastewater passing through the grid enters the sump 1, with a total volume of 20 cubic meters. The wastewater enters the first regulating tank 2 through a pump, and 400L of ferrous sulfate solution with a concentration of 27g / L is added. Aeration and stirring for 15 minutes; (2) Then enter the first sedimentation tank 3 through the pump, and stir while adding cationic polyacrylamide (50 ionicity) with a molecular weight of 12 million until the mud and water in the first sedimentation tank 3 are separated; (3) Pump the solution in the upper layer into the oxida...

Embodiment 3

[0023] Such as figure 1 As shown, the coking wastewater pretreatment system includes a sump 1, a first regulating pond 2, a first sedimentation pond 3, an oxidation pond 4, a second regulating pond 5, a second Pool 7 and packed tower 8. Both the first sedimentation tank 3 and the second sedimentation tank 6 are connected with a sludge tank 9 through a pump.

[0024] Coking wastewater pretreatment method: (1) The coking wastewater passing through the grid enters the sump 1, with a total volume of 20 cubic meters. The wastewater enters the first regulating tank 2 through a pump, and 600L of ferrous sulfate solution with a concentration of 25g / L is added. Aeration and stirring for 20 minutes; (2) Enter the first sedimentation tank 3 through the pump, and stir while adding cationic polyacrylamide (80 ionicity) with a molecular weight of 12 million until the mud and water in the first sedimentation tank 3 are separated; (3) Pump the solution in the upper layer into the oxidation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com