Preparation process of titanium nitride-coated artificial joint

An artificial joint and preparation process technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of easy peeling, low coating crystallinity, weak bonding strength, etc., and achieve a good biological phase. Compatibility and biological activity, simple equipment and preparation process, effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

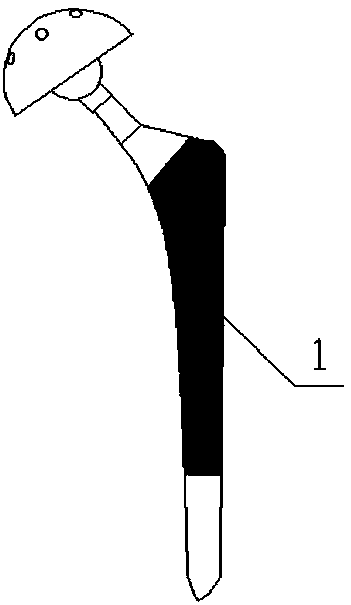

[0022] Titanium Nitride Coating Fabrication for Artificial Hip Prosthesis.

[0023] The femoral part of the artificial hip joint prosthesis is made of titanium-based metal. The surface is ground and polished, and after ultrasonic cleaning, it is placed in a glow ion nitriding furnace to protect the surface that does not need coating, and place it at the cathode position After sealing, when the vacuum is evacuated to 100Pa-200Pa, turn on the power and start arcing. When the voltage increases to 400~800V, the glow is ignited, and the glow flash point appears on the surface of the sample. A small amount of ammonia gas is introduced to control the test temperature. The temperature is 900°C, adjust the voltage and current to stabilize the pressure in the furnace at about 300Pa, and last for 4 hours. After the reaction is completed, cool down to room temperature with the furnace.

Embodiment 2

[0025] Titanium Nitride Coating Fabrication for Artificial Hip Prosthesis.

[0026] The tibial part of the artificial knee joint prosthesis is made of titanium-based metal. The surface is ground and polished, and after ultrasonic cleaning, it is placed in a glow ion nitriding furnace to protect the surface that does not need coating and place it at the cathode position After sealing, when the vacuum is evacuated to 100Pa-200Pa, turn on the power and start arcing. When the voltage increases to 400~800V, the glow is ignited, and the glow flash point appears on the surface of the sample. A small amount of ammonia gas is introduced to control the test temperature. The temperature is 900°C, adjust the voltage and current to stabilize the pressure in the furnace at about 300Pa, and last for 4 hours. After the reaction is completed, cool down to room temperature with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com