Organically modified silica sol and preparation method thereof

A silica and organosilicon technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as non-aqueous systems that cannot be directly applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Method embodiment 1 of the present invention: it comprises the following steps:

[0028] (1) Dissolve 20ml of tetraethyl orthosilicate in 50ml of N,N-dimethylformamide under stirring conditions at room temperature to prepare mixed solution A.

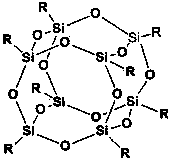

[0029] (2) Measure 20ml of N,N-dimethylformamide into a three-necked flask under stirring at room temperature, add 2 drops of ammonia water, 1.5ml of deionized water and 0.01g of trisilanol phenyl POSS , to make mixed solution B.

[0030] (3) Add the mixed solution in A dropwise to the mixed solution B at a certain temperature under the condition of stirring. After the dropwise addition, stir for 10-12 hours, transfer the mixed solution to a beaker, and seal it with a parafilm. Prick several small holes on the sealing film, seal and store at room temperature for 1-15 days to obtain POSS modified nano-silica sol.

Embodiment 2

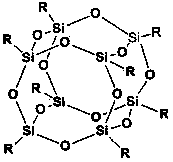

[0032] (1) Dissolve 10ml of tetraethyl orthosilicate and 0.01g of octaaminophenyl POSS in 30ml of isopropanol under stirring at room temperature to make mixed solution A.

[0033] (2) At room temperature and under stirring conditions, measure 10ml of N,N-dimethylformamide in a three-necked flask, add 0.1ml of tetramethylammonium hydroxide and 1ml of deionized water to make a mixed solution b.

[0034] (3) Add the mixed solution in A to the mixed solution B dropwise at a certain temperature and under stirring conditions, stir for 10-12 hours, transfer the mixed solution to a beaker, seal it with a parafilm, and tie it on the parafilm Several small holes are sealed and stored at room temperature for 1-15 days to obtain POSS-modified nano silica sol.

Embodiment 3

[0036] (1) Dissolve 10ml of tetraethyl orthosilicate in 30ml of N,N-dimethylformamide under stirring at room temperature to make mixed solution A.

[0037] (2) Under room temperature and stirring conditions, measure 10ml of N,N-dimethylformamide in a three-necked flask, add 0.77ml of deionized water, 3 drops of acetic acid and 0.05g of carboxyl-terminated hyperbranched polyester , to make mixed solution B.

[0038] (3) Add the mixed solution in A dropwise to the mixed solution B at a certain temperature under the condition of stirring. After the dropwise addition, stir for 10-12 hours, transfer the mixed solution to a beaker, and seal it with a parafilm. Piercing several small holes on the sealing film, sealing and storing at room temperature for 1-15 days to obtain hyperbranched polyester modified nano-silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com