Recycling system and technique for producing wastewater by cellulosic ethanol

A technology for cellulosic ethanol and waste water production, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste of resources, need to cool below 40°C, high energy consumption, etc. , to achieve the effect of reducing the amount of external drainage, reducing the amount of waste water, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

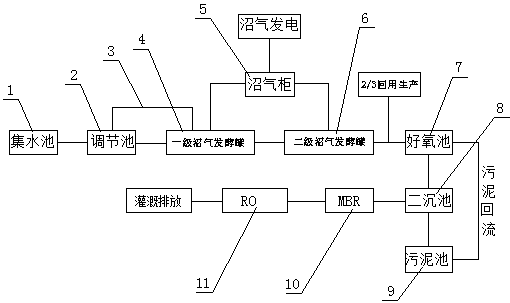

[0027] A cellulosic ethanol production wastewater recycling system, which sequentially includes a wastewater collection and adjustment module, a wastewater fermentation module and a resource utilization module, the wastewater collection and regulation module includes a sump 1 connected to the cellulosic ethanol production system and the sump 1 Connected regulating tank 2; the wastewater fermentation module includes a primary biogas fermentation tank 4, a secondary biogas fermentation tank 6 and a biogas cabinet 5, the primary biogas fermentation tank 4 is connected to the regulating pond 2, and the biogas cabinet 5 are respectively connected with the primary biogas fermentation tank 4 and the secondary biogas fermentation tank 6; the resource utilization module includes a biogas utilization module connected with the biogas cabinet 5 and connected with the secondary biogas fermentation tank 6' The biogas fermentation water utilization module uses biogas to generate electricity f...

Embodiment 2

[0034] A process method for comprehensive utilization of fiber ethanol wastewater resource utilization by using the fiber ethanol production wastewater recycling system of the first embodiment, comprising the following steps:

[0035] 1) Wastewater fermentation:

[0036] COD Cr Cellulosic ethanol production wastewater with a content of 40,000mg / L, a pH of 5, and a water temperature of 60°C is calculated as 1,000m 3 / d is collected by the sump 1 and enters the adjustment tank 2, the reflux ratio is controlled to 1:3, the temperature of the wastewater is adjusted to 58°C, and the pH is 5.2; the mixed water after reflux adjustment enters the first-level biogas fermentation tank 4, and the high-temperature anaerobic Oxygen fermentation, volume load using 15 kgCOD Cr / m 3 .d, 82% conversion of organic matter into biogas, COD Cr The content is reduced to 7200 mg / L, the temperature of the first-stage biogas fermentation effluent is 50°C, and the pH is 6.5. 1 / 4 of the effluent flo...

Embodiment 3

[0040] A process method for comprehensive utilization of fiber ethanol wastewater resource utilization by using the fiber ethanol production wastewater recycling system of the first embodiment, comprising the following steps:

[0041] 1) Wastewater fermentation:

[0042] COD Cr Cellulosic ethanol production wastewater with a content of 50,000 mg / L, a pH of 5.8, and a water temperature of 55°C is based on 1,000 m 3 / d After being collected by the collection pool 1, it enters the regulating pool 2, and the reflux ratio is controlled to be 1:3.5 to realize the temperature and pH adjustment of the production wastewater, and the water temperature is fine-tuned through the heat exchanger. The temperature is 56°C and the pH is 6; The regulated mixed water enters the primary biogas fermentation tank 4 from the regulating tank 2, adopts high-temperature anaerobic fermentation, and adopts 20 kgCOD volume load Cr / m 3 .d, 85% conversion of organic matter into biogas, COD Cr content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com