Preparation method for halogen-free flame retardant and flame retardant polyolefin composition thereof

A composition and polyolefin technology, applied in the preparation of halogen-free flame retardants, the field of flame retardant polyolefin compositions, can solve the problems of easy discoloration, low yield, low yield, etc., and achieve excellent physical properties, high purity, The effect of high flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

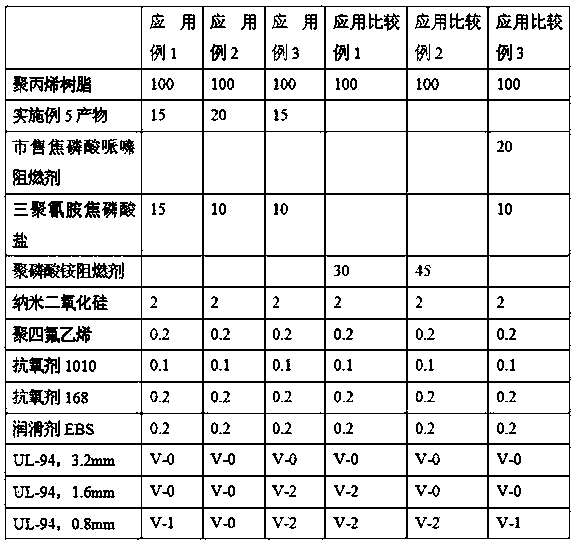

Examples

Embodiment 1

[0061] Weigh 23 kg of phosphoric acid solution and add it to 20 L of water, dissolve 8.6 kg of piperazine in 30 L of water and add it to the phosphoric acid solution through the feeding pipe, and stir for 4 hours at room temperature. Then heat up to 60°C, connect the reaction solution to the feed pump of the spray dryer with a feed pipe, then enter the spray dryer, and centrifugally spray dry at a speed of 18000r / min. The drying hot air temperature is 150°C to obtain 28.0 kg piperazine diphosphate.

Embodiment 2

[0063] Weigh 25.4kg of phosphoric acid solution and add it to 20L of water, dissolve 8.6kg of piperazine in 30L of water and add it to the phosphoric acid solution through the feeding pipe, and stir for 4 hours at room temperature. Then the temperature was raised to 60°C, and the reaction solution was connected to the feed pump of the spray dryer with a material pipe, and then entered into the spray dryer, and was centrifugally sprayed and dried at a speed of 8000r / min, and the drying hot air temperature was 160°C to obtain 27.8 kg piperazine diphosphate.

Embodiment 3

[0065] Weigh 23kg of phosphoric acid solution and add it to 20L of water, dissolve 8.6kg of piperazine in 30L of water and add it to the phosphoric acid solution through the feeding pipe, and stir for 2 hours at room temperature. Then the temperature was raised to 70°C, the reaction liquid was connected to the feed pump of the spray dryer with a feed pipe, and then entered into the spray dryer, and was centrifugally sprayed and dried at a speed of 10000r / min, and the drying hot air temperature was 140°C to obtain 27.5 kg piperazine diphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com