Preparation method of high-purity phycocyanin

A phycocyanin and high-purity technology, applied in the field of high-purity phycocyanin preparation, can solve the problems of complex process flow, loss of activity, variability and the like, and achieve the effects of simple and efficient extraction process, wide sources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of high-purity phycocyanin, the steps are as follows:

[0030] (1) Take freshly dried spirulina powder, mix it with 0.05mol / L phosphate buffer at a ratio of 1:15 (mass / volume), stir magnetically at room temperature for 2 hours, place it at -20°C to freeze completely, take out Melt in a 37°C water bath, stir gently with a glass rod to avoid air bubbles, and freeze at -20°C after completely melting. Freezing and thawing was repeated 8 times in this way, centrifuged at 4°C and 8000rpm for 30min, and the supernatant was taken.

[0031] (2) Add solid ammonium sulfate to the supernatant of step (1) to a saturated concentration of 30%, let stand at 4°C for 8 hours, centrifuge at 4°C and 10,000rpm for 30min, take the supernatant, then add solid ammonium sulfate to 45% saturation Concentration, after standing at 4°C for 8 hours, centrifuge at 4°C and 10,000rpm for 30min, and take the precipitate.

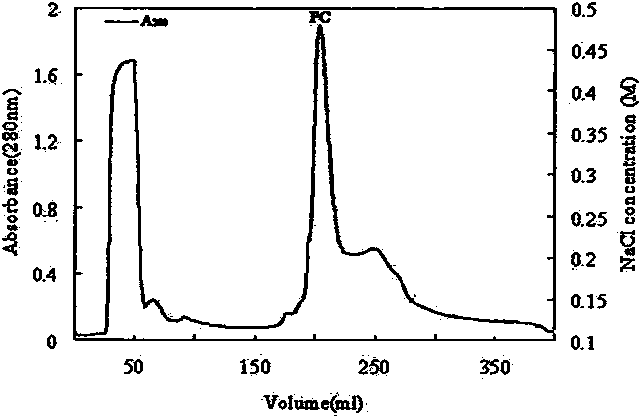

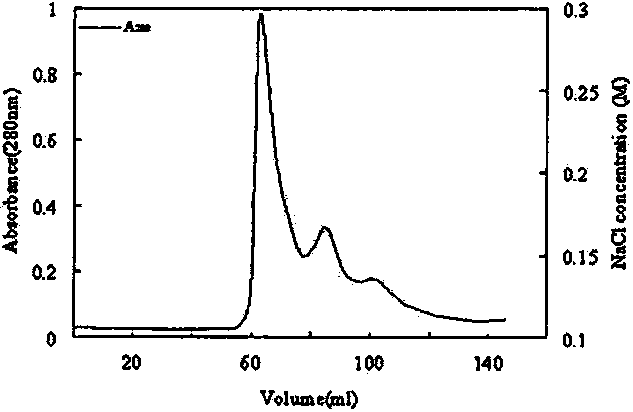

[0032] (3) Dissolve the precipitate in step (2) with a sma...

Embodiment 2

[0037] A preparation method of high-purity phycocyanin, the steps are as follows:

[0038] (1) Take fresh and dried spirulina powder, mix it with 0.05mol / L phosphate buffer at a ratio of 2:25 (mass / volume), stir magnetically at room temperature for 2 hours, place it in -20°C to freeze completely, take out Melt in a 37°C water bath, stir gently with a glass rod to avoid air bubbles, and freeze at -20°C after completely melting. Freezing and thawing was repeated 10 times in this way, centrifuged at 4°C, 10,000 rpm for 30 min, and the supernatant was taken.

[0039] (2) Add solid ammonium sulfate to the supernatant of step (1) to a saturated concentration of 25%, let stand at 4°C for 8 hours, centrifuge at 4°C and 10000rpm for 30min, take the supernatant, then add solid ammonium sulfate to 50% saturation Concentration, after standing at 4°C for 8 hours, centrifuge at 8000rpm for 30min at 4°C to collect the precipitate.

[0040] (3) Dissolve the precipitate in step (2) with a sm...

Embodiment 3

[0045] A preparation method of high-purity phycocyanin, the steps are as follows:

[0046] (1) Take fresh and dried spirulina powder, mix it with 0.05mol / L phosphate buffer saline in a ratio of 1:10 (mass / volume), stir magnetically at room temperature for 2 hours, place it at -20°C to freeze completely, take out Melt in a 37°C water bath, stir gently with a glass rod to avoid air bubbles, and freeze at -20°C after completely melting. Freezing and thawing was repeated 8 times in this way, centrifuged at 4°C and 12000rpm for 30min, and the supernatant was taken.

[0047] (2) Add solid ammonium sulfate to the supernatant of step (1) to a saturated concentration of 30%, let stand at 4°C for 8 hours, centrifuge at 12000rpm for 30min at 4°C, take the supernatant, then add solid ammonium sulfate to 55% saturation Concentration, after standing at 4°C for 8 hours, centrifuge at 12000rpm for 30min at 4°C to collect the precipitate.

[0048] (3) Dissolve the precipitate in step (2) wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com