Method for purifying cooking oil fumes through rare earth catalysis low-temperature plasma technology, and apparatus thereof

A low-temperature plasma and plasma technology, applied in the field of plasma, can solve the problems of limited removal range of pollutants, difficult maintenance, secondary pollution, etc., and achieve the effects of avoiding back corona, solving cleaning difficulties, and enhancing fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

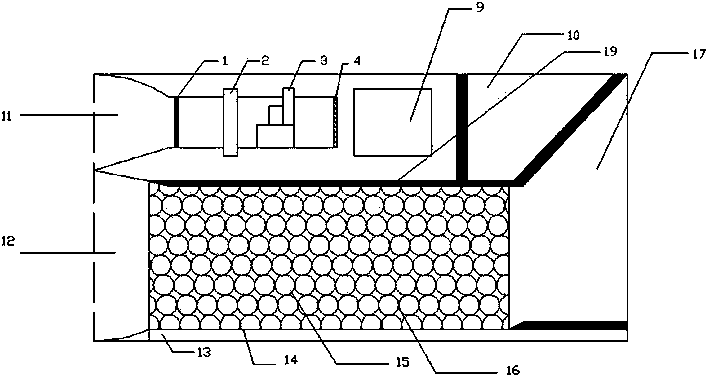

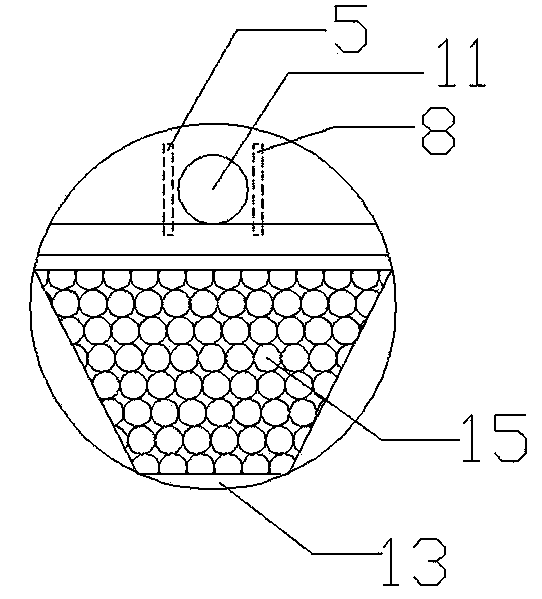

[0046] Example 1 1) The present invention adopts the plate-hole-plate corona atomization discharge plasma generation area and the adsorption catalysis synergistic plasma purification area as the basis, and adopts the atomization corona discharge method to generate plasma.

[0047] 2) Adjust the pulse voltage of the power supply to 10KV, and the discharge frequency to 50Hz.

[0048] 3) Adsorption material Al in the adsorption catalytic synergistic plasma purification zone 2 o 3 The fill rate is 70%.

[0049] 4) Adsorption material Al 2 o 3 Catalyst coating - rare earth based perovskite composite oxide (LaCoO 3 ) load is 15%.

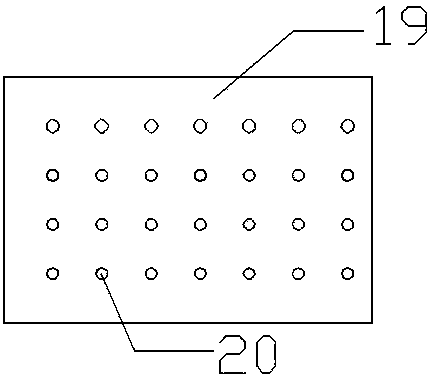

[0050] 5) A small amount of kitchen fume enters through the upper fume inlet of the casing of the present invention, passes through the filter screen, and after being dried by the drying tube, enters between the high-voltage plate electrode and the ground plate electrode through the flow equalizing network, forming a pulse current near the micropor...

Embodiment 2

[0056] Other conditions remain unchanged, and the pulse voltage of the power supply in step (2) in Example 1 is changed from 10KV to 8KV.

Embodiment 3

[0058] Other conditions remain unchanged, and the pulse voltage of the power supply in step (2) in Example 1 is changed from 10KV to 12KV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com