Preparation method for hydrophilic magnetic nano material for enrichment of glycopeptides

A magnetic nanometer and glycosylation technology, applied in the field of separation and purification of glycosylated peptides, can solve the problems of complicated operation and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

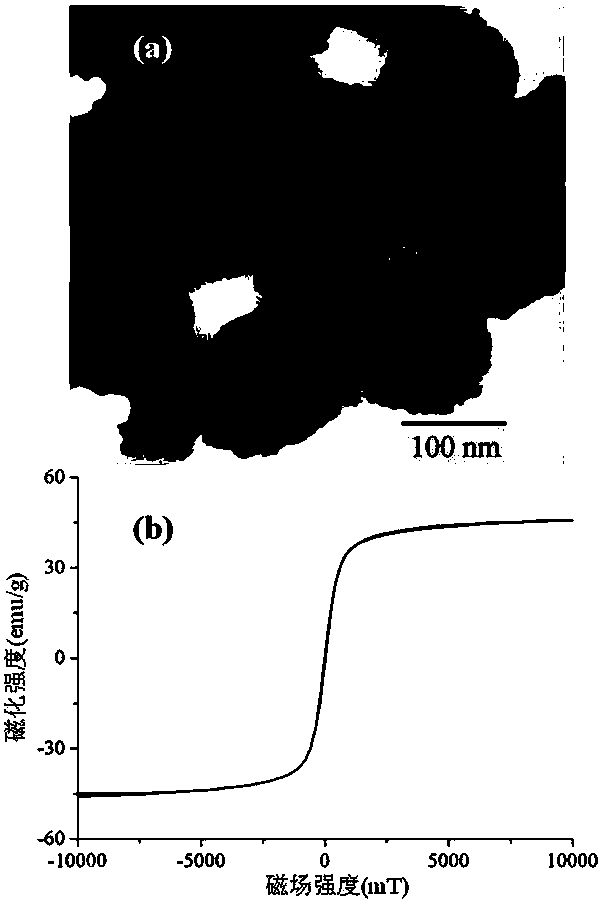

[0015] 3 g FeCl 3 ·6H 2 O was added to 70 mL of ethylene glycol, ultrasonically dissolved for 20 min to form a yellow transparent solution, and 5 g of NH 4 Ac and 1.5 g chitosan, under nitrogen protection at 150 o C heated and stirred for 2.4 h, then transferred to a 100 mL reactor for 190 o C hydrothermal reaction for 18 h. After the reaction was completed, the cooled black solution was magnetically separated, and the product was washed with high-purity water and absolute ethanol respectively, 65 o C vacuum dried. The TEM and hysteresis loops of the material are shown in figure 1 : Its size is about 140 nm, and the material maintains good magnetic properties.

Embodiment 2

[0017] 1 g FeCl 3 ·6H 2 O was added to 25 mL of ethylene glycol, ultrasonically dissolved for 10 min to form a yellow transparent solution, and 1 g of NH 4 Ac and 0.5 g cellulose, under nitrogen protection at 180 o C heated and stirred for 4 h, then transferred to a 100 mL reactor at 250 o C hydrothermal reaction for 14 h. After the reaction was completed, the cooled black solution was magnetically separated, and the product was washed with high-purity water and absolute ethanol, respectively, for 50 o C vacuum dried.

Embodiment 3

[0019] 5 g FeCl 3 ·6H 2 O was added to 100 mL of ethylene glycol, ultrasonically dissolved for 30 min to form a yellow transparent solution, and 10 g of NH 4 Ac and 4 g agarose, under nitrogen protection at 130 o C heated and stirred for 1 h, then transferred to a 100 mL reactor for 150 o C hydrothermal reaction for 24 h. After the reaction was completed, the cooled black solution was magnetically separated, and the product was washed with high-purity water and absolute ethanol, respectively, for 80 o C vacuum dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com