Preparation method of ultralight hierarchical-array-pore foam material

A foam material and array hole technology, which is applied in the field of preparation of ultra-light graded array cell foam materials, can solve the problems of demanding melting point range, high technical difficulty, easy aging and degradation, etc. The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

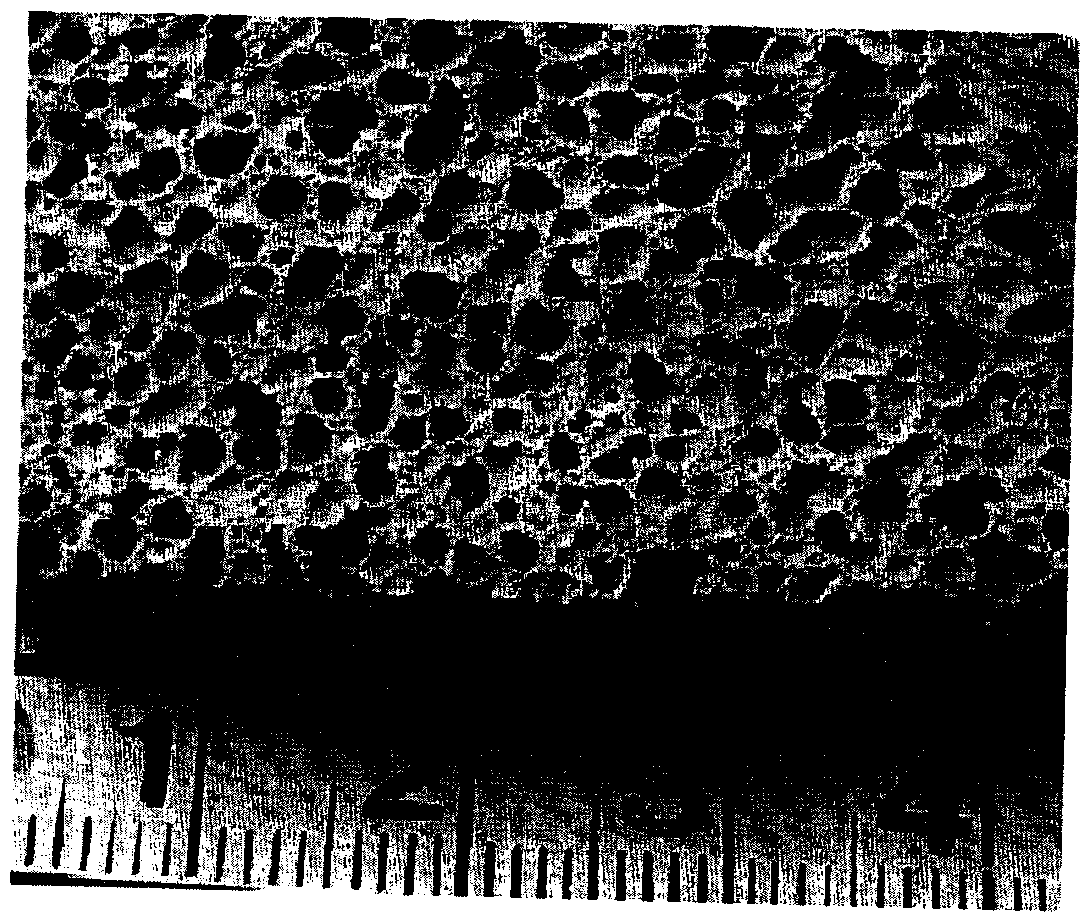

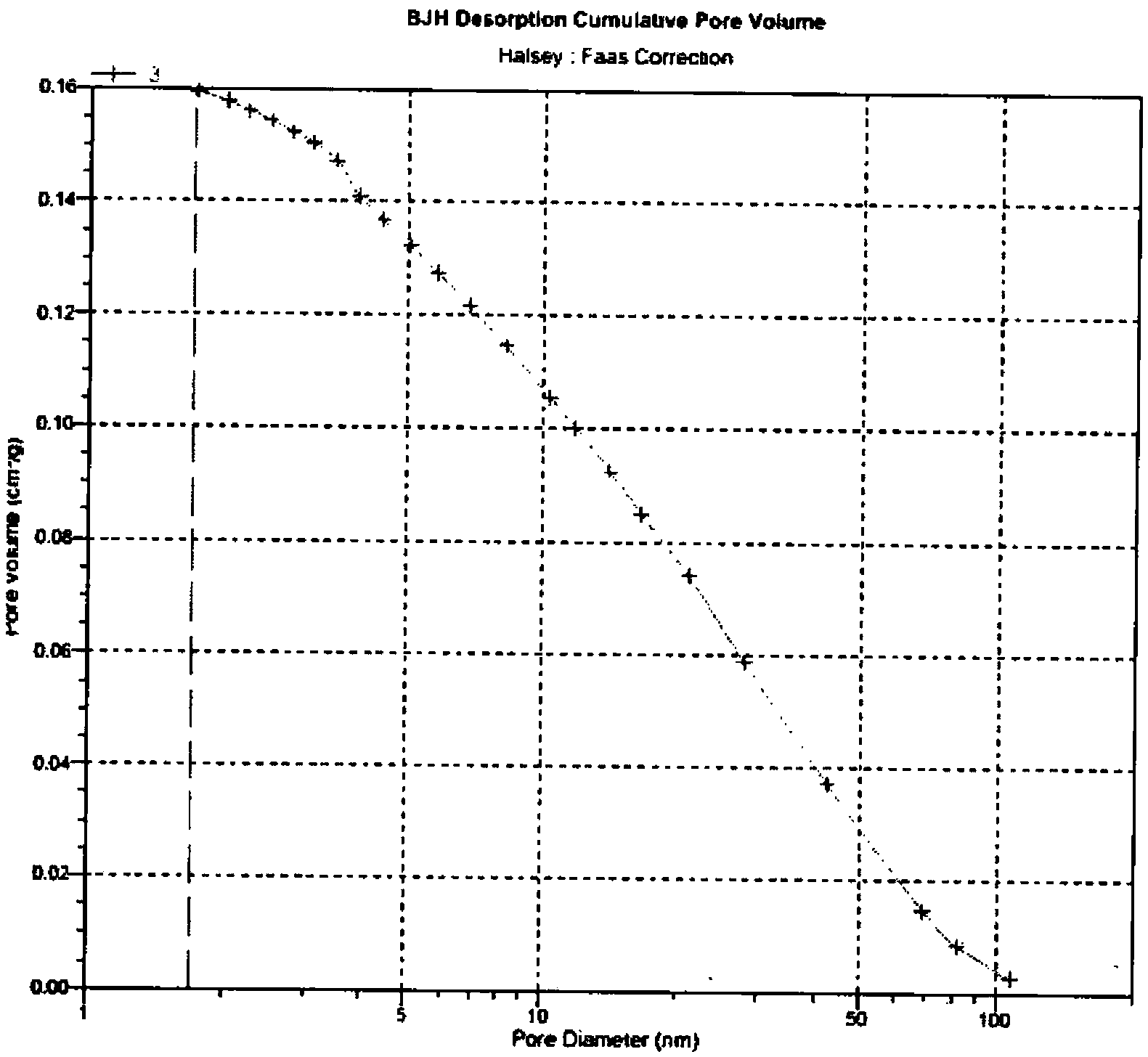

Image

Examples

Embodiment 1

[0039] Step 1 Preparation and Grinding

[0040] After the tailings discharged from the copper ore concentrator are ground and pulverized (the chemical composition is (ω%): SiO 2 44.05, Al 2 o 3 8.32, CaO17.77, MgO12.22, Fe 2 o 3 10.76, K 2 O1.12, Na 2 O0.99, other ingredients are trace. ), get it as 80% of the total weight, and quartz 2%, feldspar 2%, fluorite 6%, clay 2%, borax 5%, sodium carbonate 3% (the stated percentages are the percentage of total weight , The following examples are the same), and the sum of each component together with the copper tailings powder is 100% in total. Grind again with a high-energy ball mill to make more than 96% of the mixed powder with a particle size smaller than 0.034mm;

[0041] Step 2 Mineral powder infiltration

[0042] Mix the mineral powder in step 1, add a wetting solution of sodium dodecylbenzenesulfonate with a concentration of 15% by mass, stir it and place it for 4 hours, and keep the mass (g) of the mixed mineral powd...

Embodiment 2

[0050] Step 1 Preparation and Grinding

[0051] After grinding and pulverizing the tailings formed during iron ore development and beneficiation (the chemical composition is (ω%): SiO 2 30.09, Al 2 o 3 11.73, CaO5.64, MgO4.33, Fe 2 o 3 28.02, K 2 O0.55, Na 2 O1.78, traces of other ingredients. ), taking it as 50% of the total weight, and then adding a component regulator, wherein 15% of quartz, 8% of feldspar, 5% of fluorite, 5% of limestone, 5% of clay, 5% of borax, 7% of sodium carbonate, each The sum of the ingredients together with the tailings powder adds up to 100%. Grind again with a high-energy ball mill to make more than 96% of the mixed mineral powder with a particle size of less than 0.034mm;

[0052] Step 2 Mineral powder infiltration

[0053] Mix the powder in step 1, add the wetting solution containing sodium dodecylsulfonate with a concentration of 3% by mass, stir it and leave it for 3 hours, and keep the mass (g) of the mixed mineral powder and wettin...

Embodiment 3

[0059] Step 1 Preparation and Grinding

[0060] After grinding the tailings formed during gold mine development (its chemical composition is (ω%): SiO 2 66.39, Al 2 o 3 4.97, CaO4.92, MgO3.54, Fe 2 o 3 14.63,K 2 O1.58, Na 2 O0.81, trace amounts of other components. ), which is taken as 70% of the total weight, mixed with 10% feldspar, 1% fluorite, 6% clay, 4% borax, 5% dolomite, 4% sodium carbonate, each component is added together with gold tailings powder Add up to 100%. Grind again with a high-energy ball mill to make a mixed powder with more than 96% of the particle size smaller than 0.034mm.

[0061] Step 2 Mineral powder infiltration

[0062] Mix the mineral powder in step 1, add a mixed wetting solution composed of 2.5% sodium dodecylbenzenesulfonate and 2.5% sodium cetylsulfonate in mass percent concentration, stir well and place it for 5h, keep The mass (g): volume (ml) ratio of the mixed mineral powder to the wetting solution is 1:0.15.

[0063] Step 3 foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com