Method for coupling extraction and fermentation to separate 2,3-butanediol in fermentation broth

A technology of butanediol and fermented liquid, which is applied in the field of bioengineering, can solve the problems of difficult recycling and excessive waste water discharge, and achieve the effects of avoiding high salt concentration, reducing treatment and discharge, and low energy consumption for separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation of 2,3-butanediol fermentation broth:

[0036] (1) Inoculate Enterobacter cloacae into the seed culture medium, and culture it on a shaker at 35-38° C. and 200-300 rpm for 12-18 hours;

[0037] (2) Insert the bacterium culture liquid of step (1) into the fermentation medium according to the inoculum amount of 10%, and culture it on a shaker at 37°C and 200rpm for 48-90h to obtain 2,3-butanediol fermentation liquid, and the fermentation ends When the residual sugar concentration is 10~15g / L.

[0038] In a specific embodiment, the bacterium culture solution in step (1) can also be fermented in a fermenter, specifically: with Biotech5L full-automatic fermenter, the bacterium culture solution in step (1) is inoculated with 10% inoculum Put it into 2L fermentation medium, control the pH to 5.8 with 5mol / L NaOH, and ferment at 37°C and 250r / min. Keep 200ml / L in the fermentation process. min compressed air, the initial concentration of glucose is 135g / L, soli...

Embodiment 1

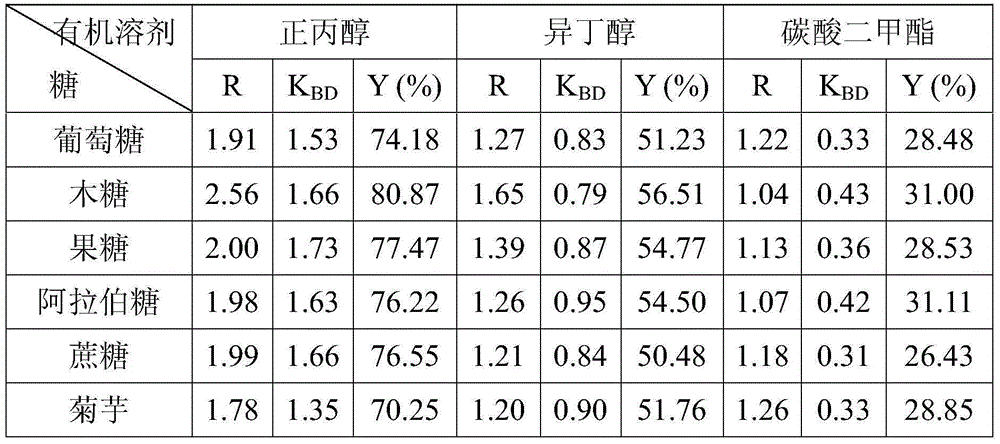

[0053] The influence of different sugars of embodiment 1 on the separation effect of 2,3-butanediol

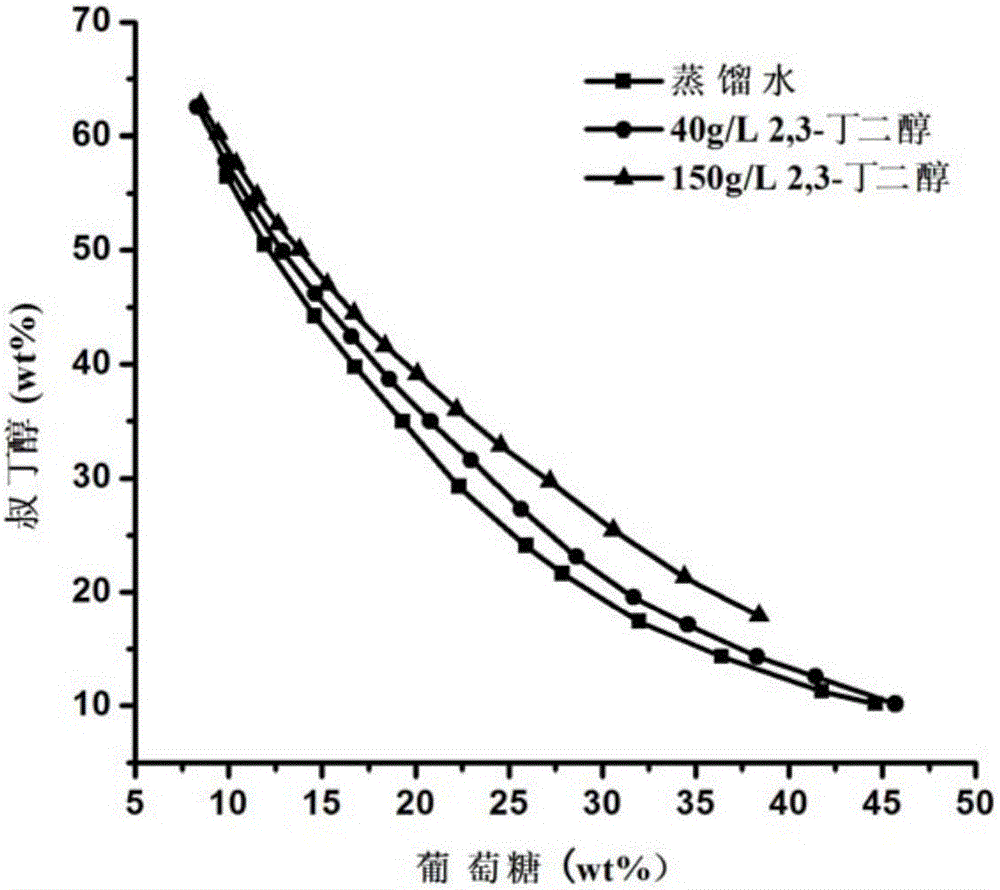

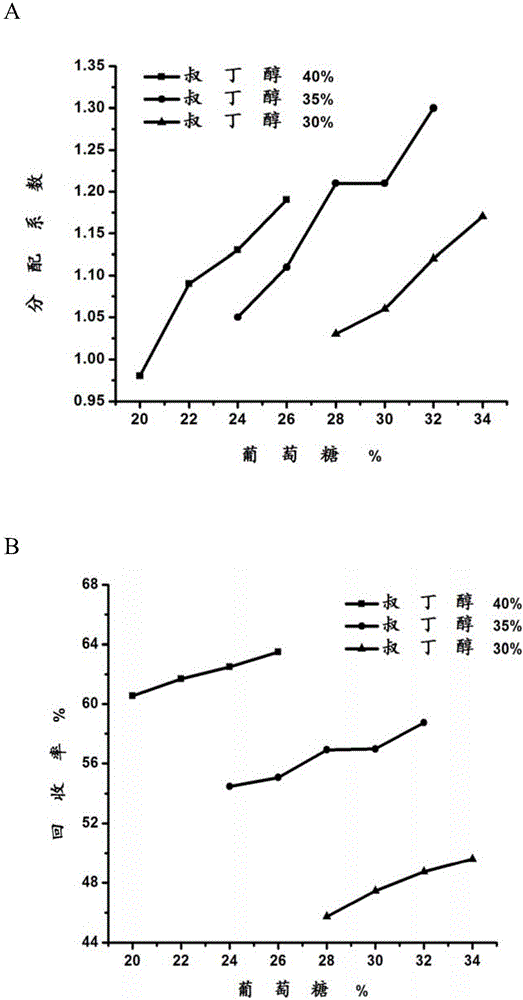

[0054] According to the method described in step 1)-3) in the above-mentioned 3 (from 2,3-butanediol fermentation broth or 2,3-butanediol fermentation liquid, the method for isolating 2,3-butanediol) from 2 , 2,3-butanediol was separated from 3-butanediol fermentation supernatant. Wherein, the concentration of 2,3-butanediol in the 2,3-butanediol fermentation clear liquid is 85.54g / L, and in the 2,3-butanediol fermentation clear liquid, add different kinds of sugar (the kind of sugar, such as Table 1) After dissolving, add different organic solvents (organic solvent types, such as Table 1), mix, stand at room temperature, separate phases, take samples to measure the concentration of 2,3-butanediol in the upper phase and the lower phase, and calculate 2 , the partition coefficient of 3-butanediol (K BD ) and recovery (Y); and measure compared to (R), the results are shown in ...

Embodiment 2

[0058] The influence of embodiment 2 different organic solvents on 2,3-butanediol separation effect

[0059] According to the method described in step 1)-3) in the above-mentioned 3 (from 2,3-butanediol fermentation broth or 2,3-butanediol fermentation liquid, the method for isolating 2,3-butanediol) from 2 , 2,3-butanediol was separated from 3-butanediol fermentation supernatant. Among them, the concentration of 2,3-butanediol in the 2,3-butanediol fermentation liquid is 69.70g / L, and the 2,3-butanediol fermentation liquid is added to the 2,3-butanediol fermentation liquid 15% and 30% of the mass of glucose are dissolved to obtain a sugary mixture. Add different organic solvents (types of organic solvents, as shown in Table 2) to the two kinds of sugar-containing mixed liquids respectively, and mix them. The volume ratio of the organic solvents to the 2,3-butanediol fermentation clear liquid is 1:1. Separate the phases, take samples to measure the concentration of 2,3-butan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com