A kind of fluorosilicone copolymer and preparation method thereof

A technology of fluorosilicon copolymer and methyltrifluoropropylcyclotrisiloxane, which is applied in the field of organosilicon synthesis chemistry, can solve the problems of insufficient temperature resistance and solvent resistance, and achieve good high temperature resistance and low temperature resistance Performance, broad application prospects, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

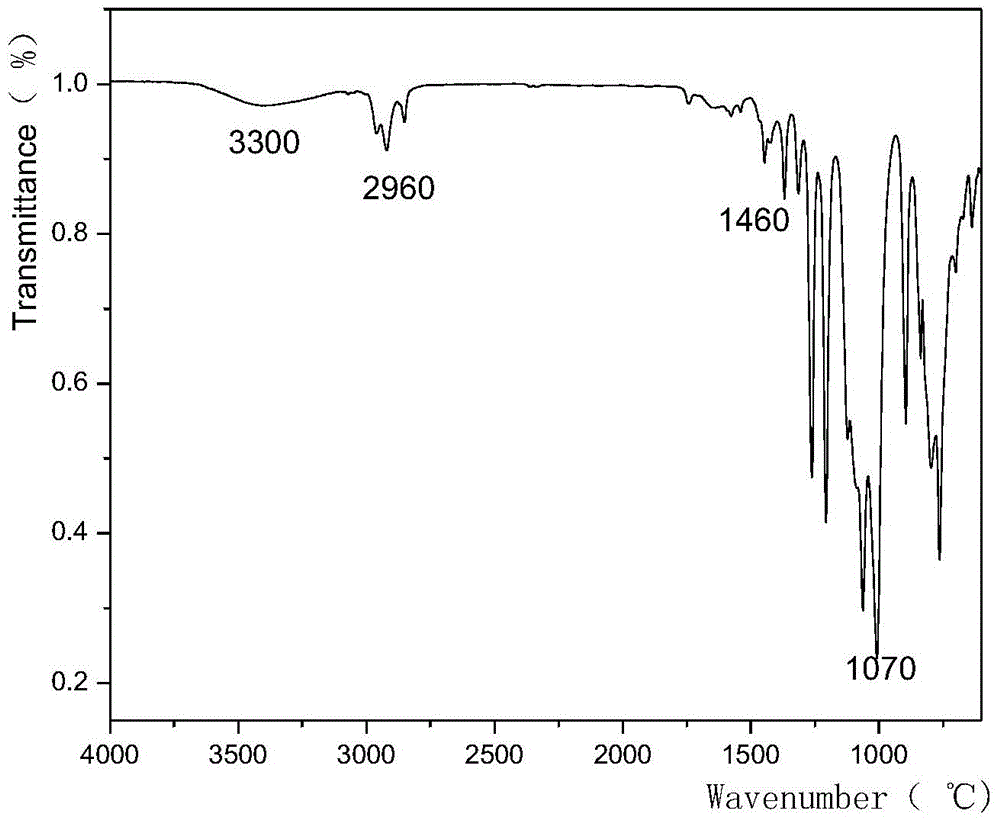

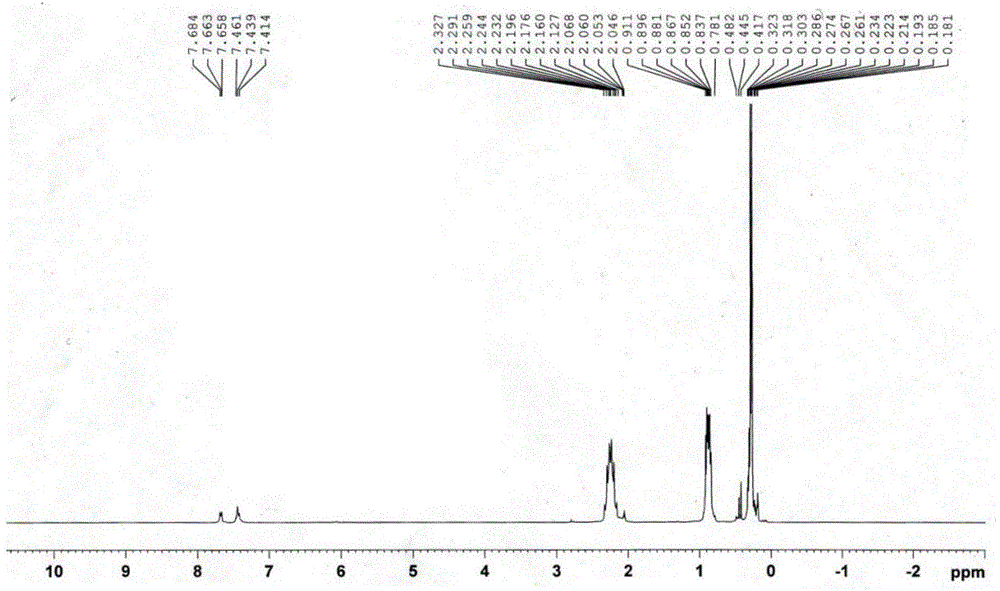

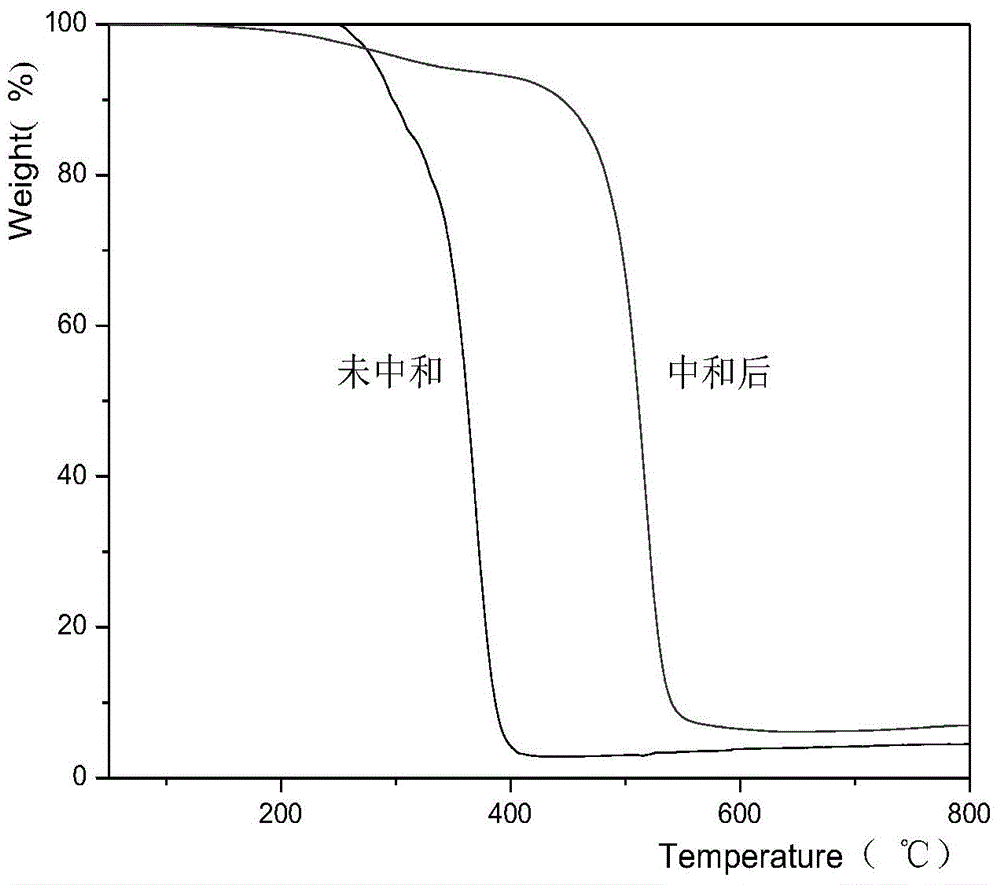

Method used

Image

Examples

Embodiment 1

[0040] To prepare a copolyfluorosilicone rubber with a molar ratio of methylphenylsiloxane chain links of 3.7%:

[0041] (1) 4.41g methyl phenyl cyclosiloxane, 94.32 g methyl trifluoropropyl cyclotrisiloxane, and 1.27 g tetramethyl tetravinyl cyclosiloxane (D 4 Vi ) Was added to the reactor one by one, and kept at a constant temperature of 60°C for 30 minutes under vacuum to remove moisture and CO 2 Impurities

[0042] (2) Raise the temperature to 130°C, add 0.01% of the total mass of the reactants (denoted by alkali metal hydroxide) sodium siliconate and 0.01% mass fraction of tributyl phosphate. Under normal pressure, N 2 In the atmosphere, under the action of mechanical stirring, after the system starts to wrap around the shaft, stop stirring and continue the equilibrium reaction for 2.5h;

[0043] (3) Add 0.1g of glacial acetic acid, mix uniformly on a mixer, heat up to 160°C to remove small molecules in vacuum, and cool down to discharge. The raw rubber is added to the Soxhlet ...

Embodiment 2

[0047] To prepare a copolyfluorosilicone rubber with a molar ratio of methylphenylsiloxane chain links of 7.2%:

[0048] By changing the ratio of methyl phenyl siloxane ring body and methyl trifluoropropyl siloxane ring body, copolymerized fluorosilicone rubber with different molar ratios of methyl phenyl siloxane chain links can be prepared.

[0049] In this embodiment, a copolyfluorosilicone rubber with a molar ratio of methyl phenylsiloxane chain links of 7.2% was selected for the preparation. The quality of raw materials required to prepare 100g of copolyfluorosilicone rubber is given in Table 1 below.

[0050] Table 1 The quality of raw materials required to prepare 100g of methylphenylsiloxane chain link molar ratio of 7.2% copolyfluorosilicone rubber

[0051]

[0052] The preparation process is to keep the temperature at 60℃ for 30min under vacuum condition, after removing the water, N 2 Replace three times to remove residual O 2 , CO 2 . After the water is removed, add 0.01% ...

Embodiment 3

[0055] A copolyfluorosilicone rubber with a molar ratio of methyl phenylsiloxane segments of 9.6% was prepared.

[0056] Through this embodiment, a copolyfluorosilicone rubber with a molar ratio of methyl phenyl siloxane chain links of 9.6% was selected to prepare. Table 2 below shows the quality of raw materials required to prepare 100 g of copolyfluorosilicone rubber.

[0057] Table 2 The quality of raw materials needed to prepare 100g of methylphenylsiloxane chain link molar ratio of 9.6% copolyfluorosilicone rubber

[0058]

[0059] The preparation process is to keep the temperature at 60℃ for 30min under vacuum condition, after removing the water, N 2 Replace three times to remove residual O 2 , CO 2 . After the moisture is removed, at 130°C, 0.01% of the total mass of the reactants and 0.01% of the total mass of the reactants are added with tributyl phosphate. In this example, NaOH is used (the mass fraction is prepared as 2% sodium siloxanol alkali gel 0.5g), under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com