Composition for biofilm and biofilm using same

A technology of biomass film and composition, applied in the field of biomass for food by-products, capable of solving problems such as low water resistance, oil resistance and gas barrier performance, impossibility to perform continuous work, and reduced processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

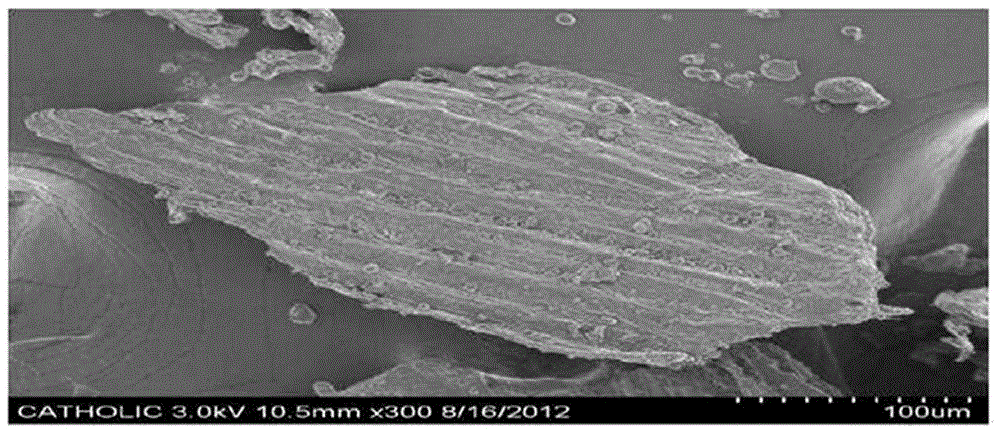

Image

Examples

example 1

[0038] Preparation of mixture containing green agricultural waste 1

[0039] Wheat bran is dried to a moisture content of 5%, firstly pulverized by a ball mill, and passed through a 150-200 mesh sieve, and air jet mill (Micro-Jet Mill System, obtained from HANKOOK PULVERIZING MACHINERY Co. , LTD.) Further pulverize the obtained powder. 100 parts by weight of prepared wheat bran powder, 15 parts by weight of calcium carbonate (which contains 10% of calcium carbonate with a size of 100 nm based on 100% of calcium carbonate), 1 part by weight of calcium stearate and 5 parts by weight of TEG was kneaded at a high speed for 15 minutes while gradually heating from 80°C to 110°C, thereby preparing filled porous green agricultural waste (biomass).

example 2

[0040] Preparation of mixture containing green agricultural waste 2

[0041] Porous green biomass was prepared in the same manner as in Example 1 except that 5 parts by weight of carrageenan was further added.

[0042] Preparation of Compositions for Biomass Films

[0043]100 parts by weight of LLDPE, 120 parts by weight of the filled porous green biomass of Example 1, 5 parts by weight of glycidyl methacrylate and 5 parts by weight of calcium stearate were mixed at 80°C to 110°C using a mixer. Mix on low for 25 minutes (Example 3). Additionally, a composition (Example 4) was prepared using a mixture comprising the red algae extract of Example 2.

[0044]

[0045] The compositions for biomass films of Examples 3 and 4 were extruded to prepare biomass films. as in figure 2 As seen in , the bran is dispersed in the membrane.

example 7

[0047] The resin mixture of Example 3 was further mixed with 10 parts by weight of SEBS to prepare a composition, which was then fabricated into a biomass film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com