Method and system for manufacturing compressed natural gas through low concentration gas

A low-concentration gas, compressed natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of waste of resources, low separation coefficient, increased energy consumption, etc., achieve high recovery rate, high methane recovery rate, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

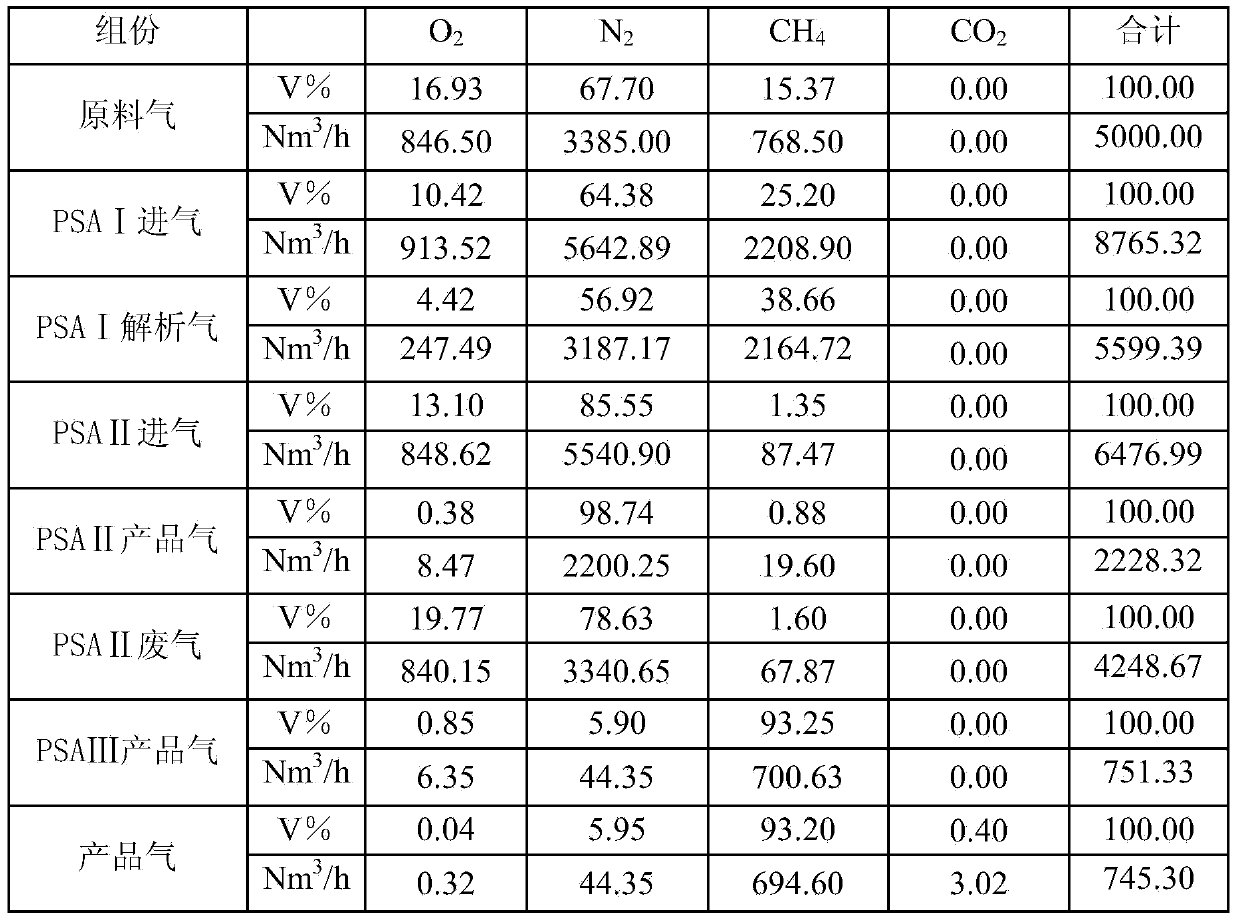

[0049] Table 1 Low concentration gas components

[0050] Component

O 2

N 2

CH 4

pressure MPa

Flow Nm 3 / h

V%

16.93

67.70

15.37

0.003

5000

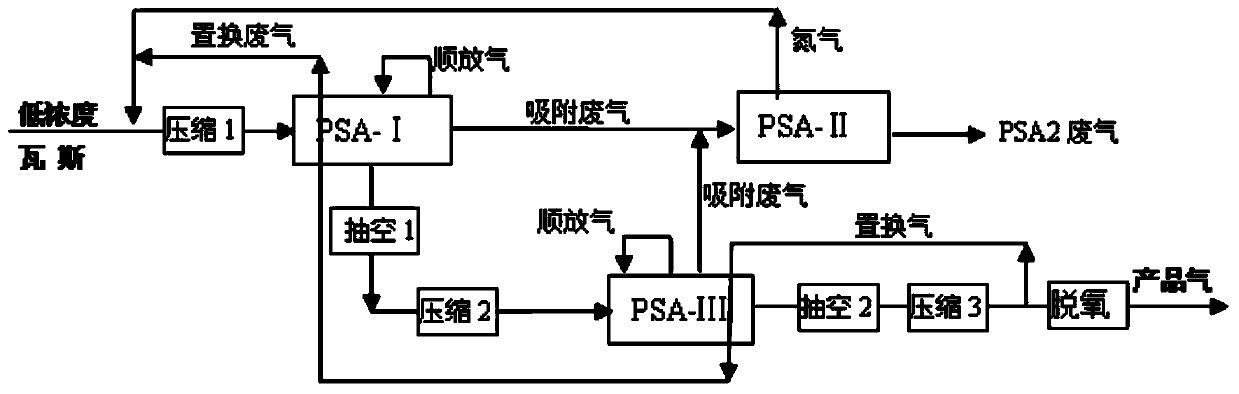

[0051] The system for producing compressed natural gas using low-concentration gas in this embodiment includes three pressure swing adsorption systems and a deoxidation system. The compressor 1 is connected to the pressure swing adsorption system I, and the pressure swing adsorption system I is connected to the pressure swing adsorption system II. The pressure adsorption system I is connected with the pressure swing adsorption system III through the compressor 2, and the pressure swing adsorption system III is connected with the deoxygenation system through the compressor 3, and the deoxygenation system is connected with the cooler, the gas-water separator, and the compressor 4 in sequence, and the pressure swing The nitrogen outlet of adsorption system II is connected to ...

Embodiment 2

[0056] Table 3 Low concentration gas components

[0057] Component

O 2

N 2

CH 4

pressure MPa

Flow Nm 3 / h

V%

15.5

62.0

22.5

0.003

10000

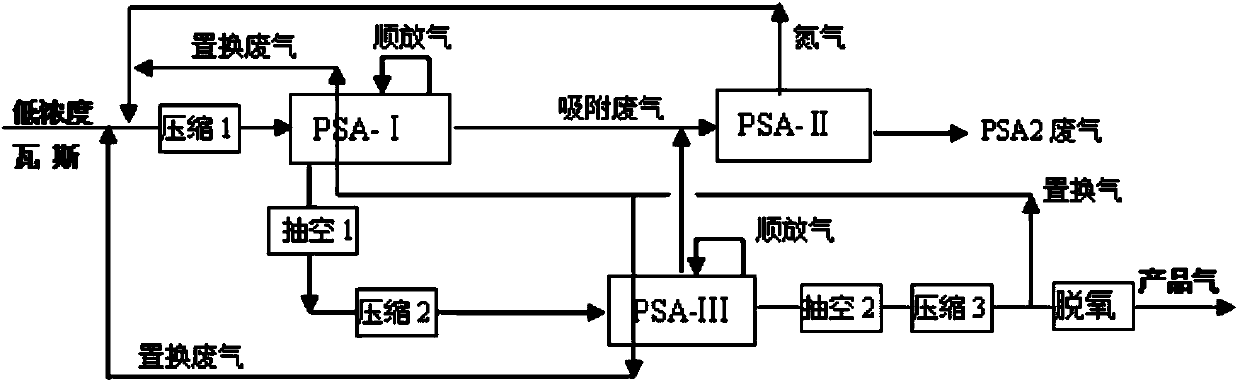

[0058] The process flow of the method for producing compressed natural gas using low-concentration gas in this embodiment is as follows: figure 2As shown in Table 3, the components of raw material low-concentration gas are shown in Table 3. During the start-up stage, pressure swing adsorption II air nitrogen production is first started, and low-concentration gas from outside the boundary is mixed with nitrogen, and the raw material compressor is pressurized to 0.4MPa. It enters PSA I to enrich methane, and the adsorbed waste gas enters PSA II to recover nitrogen, and the nitrogen obtained returns to the inlet of compressor 1, and the degassing of PSA I directly enters the regenerated adsorption tower, and PSA I concentrates After the methane mixture is pressurized to 0.4MP...

Embodiment 3

[0063] Table 5 Low concentration gas components

[0064] Component

O 2

N 2

CH 4

pressure MPa

Flow Nm 3 / h

V%

14.0

56.0

30

0.003

10000

[0065] The components of the raw material gas low-concentration gas in this embodiment are shown in Table 5. In the start-up stage, the pressure swing adsorption II air nitrogen production is first started, and the low-concentration gas from outside the boundary is mixed with the nitrogen gas, and the pressure is increased to 0.3 by the raw material compressor. After MPa, it enters pressure swing adsorption I to enrich methane, and the adsorbed waste gas enters pressure swing adsorption II to recover nitrogen, and the obtained nitrogen returns to the inlet of compressor 1, and the degassing of pressure swing adsorption I directly enters the regenerated adsorption tower, and pressure swing adsorption I extracts The dense methane mixed gas is pressurized to 0.5MPa and then enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com