An anticoagulant soil element polypeptide and its enzymatic hydrolysis preparation method and application

An anti-coagulation and soil-element technology, which is applied to medical preparations containing active ingredients, blood diseases, pharmaceutical formulations, etc., can solve the problem of no further separation and purification, achieve a simple and easy-to-understand structure, and improve bioavailability. , the effect of efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

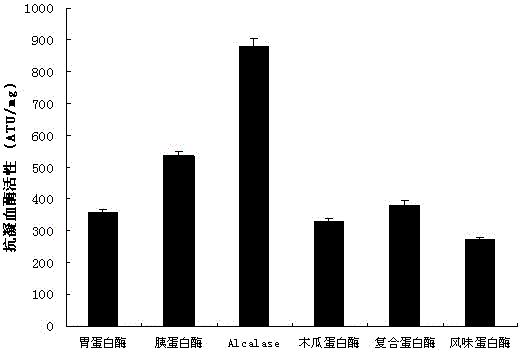

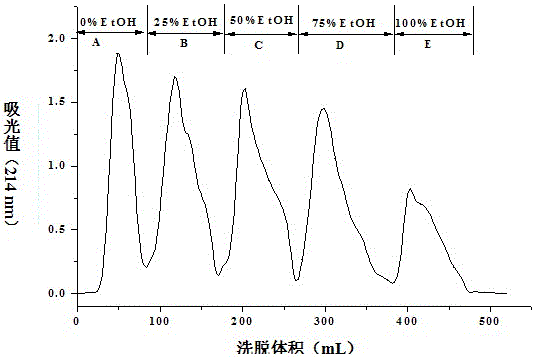

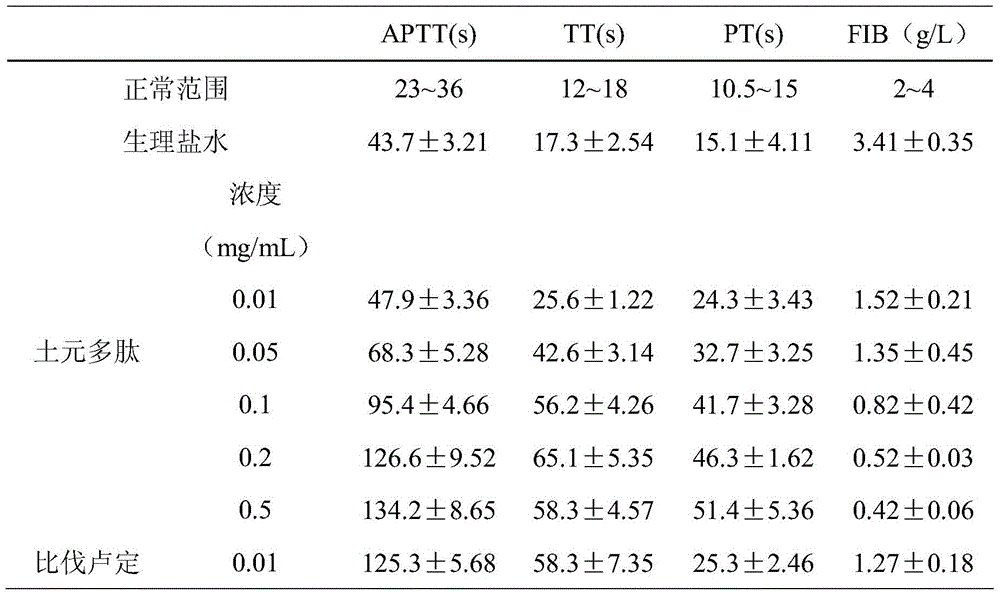

Embodiment 1

[0033]Take 500g of clean Tuyuan dry powder, the ratio of dry powder to water is 10g:100mL, adjust the pH to 9.0, stir evenly at a speed of 200r / min for 3 hours, take the supernatant, and then adjust the pH to 4, and finally obtain protein precipitation. The pH was adjusted to 7.0, and dried to obtain earth element protein. Add the earth element protein to dissolve in water, the ratio of protein and water is 10g:100mL, control the pH value at 10, then add Alcalase2.4L alkaline protease (Novozymes company, Denmark), the ratio of enzyme volume to earth element protein weight is 1mL : 100g, the reaction temperature is 50°C, the stirring speed is 200r / min, and the reaction time is 3h. Boil for 10 minutes, pass the enzymatic solution through the macroporous adsorption resin DA201-C exchange column, gradually increase the concentration of ethanol starting from pure water, and carry out gradient elution with ethanol at different mass percentage concentrations of 0, 25, 50, 75, and 100...

Embodiment 2

[0035] Take 500g of clean Tuyuan dry powder, the ratio of dry powder to water is 15g: 100mL, adjust the pH to 9.5, stir evenly at a speed of 100r / min for 4 hours, take the supernatant, and then adjust the pH to 4.5, and finally obtain protein precipitation. The pH was adjusted to 7.0, and dried to obtain earth element protein. Add the earth element protein to dissolve in water, the ratio of protein and water is 15g:100mL, control the pH value at 9, then add Alcalase2.4L alkaline protease (Novozymes company, Denmark), the ratio of enzyme volume to earth element protein weight is 1.5 mL: 100g, the reaction temperature is 60°C, the stirring speed is 150r / min, and the reaction time is 3.5h. Boil for 10 minutes, pass the enzymatic solution through the macroporous adsorption resin DA201-C exchange column, gradually increase the concentration of ethanol starting from pure water, and carry out gradient elution with different concentrations of ethanol at 0, 25, 50, 75, and 100%, and th...

Embodiment 3

[0037] Take 500g of clean Tuyuan dry powder, the ratio of dry powder to water is 20g: 100mL, adjust the pH to 10, stir evenly at a speed of 300r / min for 5h, take the supernatant, and then adjust the pH to 5.0, and finally obtain protein precipitation. The pH was adjusted to 7.0, and dried to obtain earth element protein. Add the earth element protein to dissolve in water, the ratio of protein and water is 20g: 100mL, control the pH value at 8.5, then add Alcalase2.4L alkaline protease (Novozymes company, Denmark), the ratio of enzyme volume to earth element protein weight is 3mL : 100g, the reaction temperature is 65°C, the stirring speed is 250r / min, and the reaction time is 2h. Boil for 10 minutes, pass the enzymatic solution through the macroporous adsorption resin DA201-C exchange column, gradually increase the concentration of ethanol starting from pure water, and carry out gradient elution with different concentrations of ethanol at 0, 25, 50, 75, and 100%, and the flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com