Method for extracting soybean oil and proteins

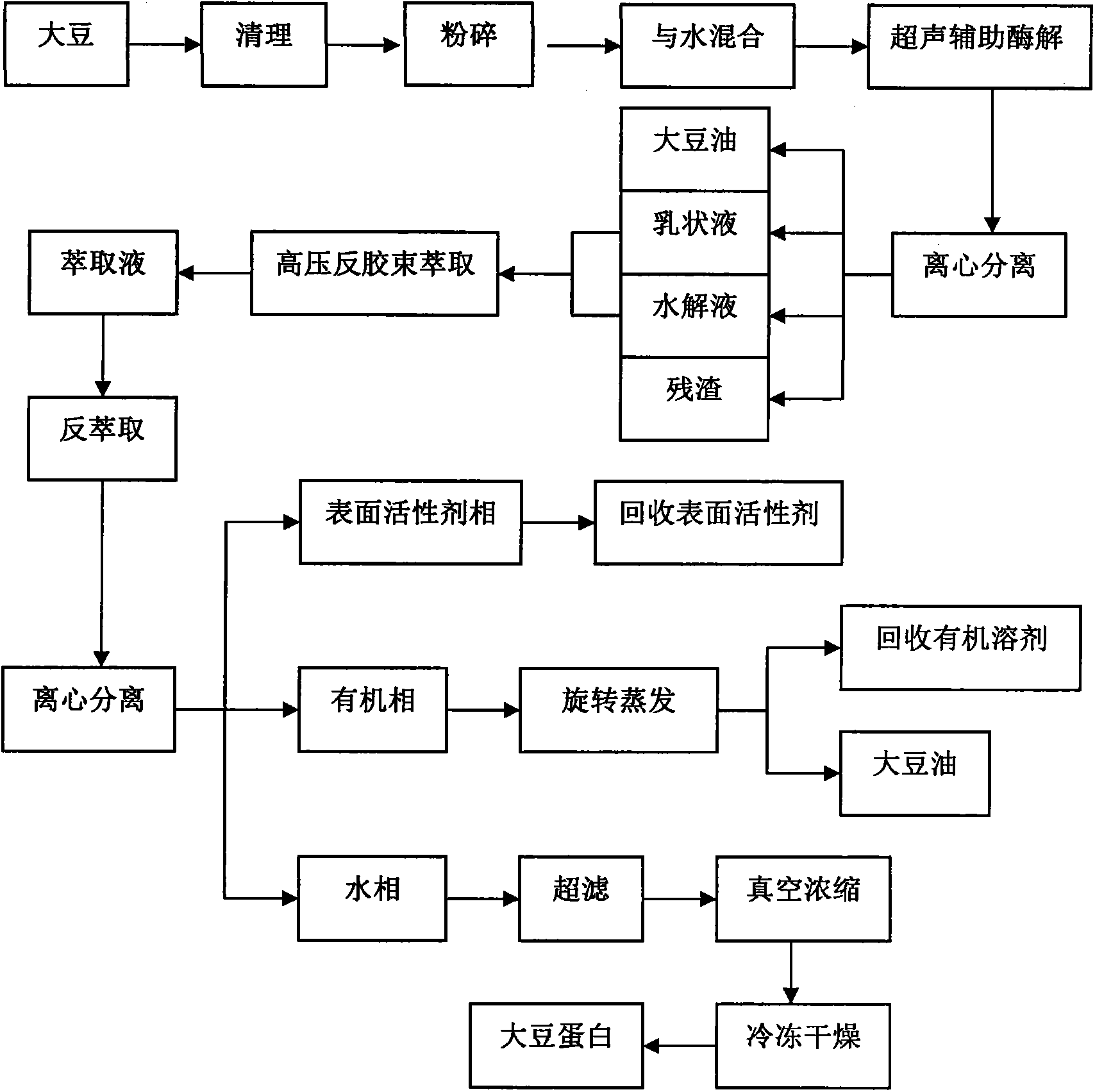

A soybean oil and protein technology, which is applied in the field of extraction and processing of vegetable oil and protein, can solve the problems of difficult research, low oil yield, difficult emulsion separation and other problems, and achieve simple process equipment, oil extraction rate and protein Improvement of extraction rate and better quality of soybean oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] After the soybeans are cleaned and crushed, they are mixed with water to form a mixed solution, and 2% alkaline protease is added to the mixed solution at an ultrasonic power of 350W, a liquid-solid ratio of 7:1mL / g, a reaction temperature of 55°C, and a reaction pH of 8.5 Ultrasonic assisted enzymolysis for 1.5h, and then centrifuged to obtain soybean oil, emulsion, hydrolyzate and residue; under the condition of ionic strength of 0.1mol / L KCl, the surfactant SDS with a concentration of 0.08g / mL and the volume ratio Mix 4:1 n-hexane / n-octanol to form SDS / n-hexane / n-octanol reverse micelle system, and add to the emulsion and hydrolyzate at an extraction pressure of 14Mpa, an extraction temperature of 50°C, and an extraction pH of 8 Add SDS / n-hexane / n-octanol reverse micelles system for high-pressure reverse micellar extraction for 10 minutes to obtain extract, mix the extract with equal volume of 1mol / L KCl solution for back extraction, and centrifuge after back extracti...

Embodiment 2

[0020] Clean and crush the soybeans and mix them with water to form a mixed solution. Add 2.5% alkaline protease to the mixed solution at an ultrasonic power of 300W, a liquid-to-solid ratio of 8:1mL / g, a reaction temperature of 60°C, and a reaction pH of 8. Ultrasound-assisted enzymolysis was carried out for 1 h, and then centrifuged to obtain soybean oil, emulsion, hydrolyzate and residue; under the condition of ionic strength of 0.1mol / L KCl, the volume ratio of the surfactant SDS with a concentration of 0.08g / mL was Mix 4:1 n-hexane / n-octanol to form SDS / n-hexane / n-octanol reverse micelle system, and add it to the emulsion and hydrolyzate at an extraction pressure of 12Mpa, an extraction temperature of 55°C, and an extraction pH of 9 The SDS / n-hexane / n-octanol reverse micellar system was subjected to high-pressure reverse micellar extraction for 15 minutes to obtain the extract, and the extract was mixed with 1mol / L KCl solution in equal volumes for back extraction, and aft...

Embodiment 3

[0022] After the soybeans are cleaned and crushed, they are mixed with water to form a mixed solution, and 1.5% alkaline protease is added to the mixed solution at an ultrasonic power of 400W, a liquid-to-material ratio of 6:1mL / g, a reaction temperature of 55°C, and a reaction pH of 7.5 Ultrasonic assisted enzymolysis for 1.5h, and then centrifuged to obtain soybean oil, emulsion, hydrolyzate and residue; under the condition of ionic strength of 0.1mol / L KCl, the surfactant SDS with a concentration of 0.08g / mL and the volume ratio Mix 4:1 n-hexane / n-octanol to form SDS / n-hexane / n-octanol reverse micelle system, and inject it into the emulsion and hydrolyzate at an extraction pressure of 16Mpa, an extraction temperature of 50°C, and an extraction pH of 7 Add SDS / n-hexane / n-octanol reverse micelles system for high-pressure reverse micellar extraction for 10 minutes to obtain extract, mix the extract with equal volume of 1mol / L KCl solution for back extraction, and centrifuge aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com