Back side dampproof and impervious structure of indoor wall of building

A backwater and wall technology, applied to building components, building insulation materials, coatings, etc., can solve problems such as failure to take waterproof and moisture-proof measures, and damage to decorative surfaces, and achieve good moisture-proof and anti-seepage effects and high adhesion , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

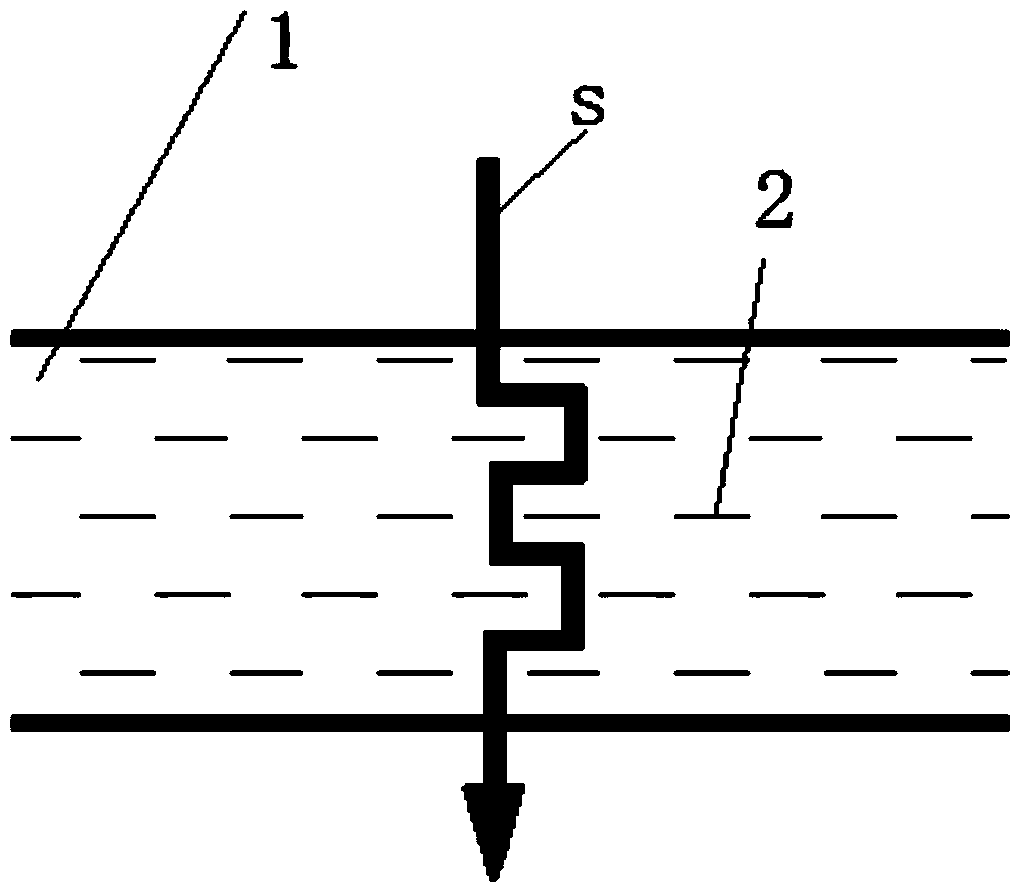

[0048] The owner of an apartment in a community is doing interior decoration and chooses ordinary interior wall latex paint as the decorative surface layer. The interior building envelope (especially the building exterior wall envelope) needs to be coated with inorganic scale water-based epoxy paint on the base layer of the moisture-proof parts. Resin paint to form a moisture-proof surface layer, and then putty and interior wall paint are applied on the moisture-proof surface layer.

[0049] The moisture-proof structure of the indoor wall in this embodiment is composed of a substrate layer composed of concrete or cement mortar, a moisture-proof surface layer, and an interior wall paint decorative layer. The specific formation process is as follows:

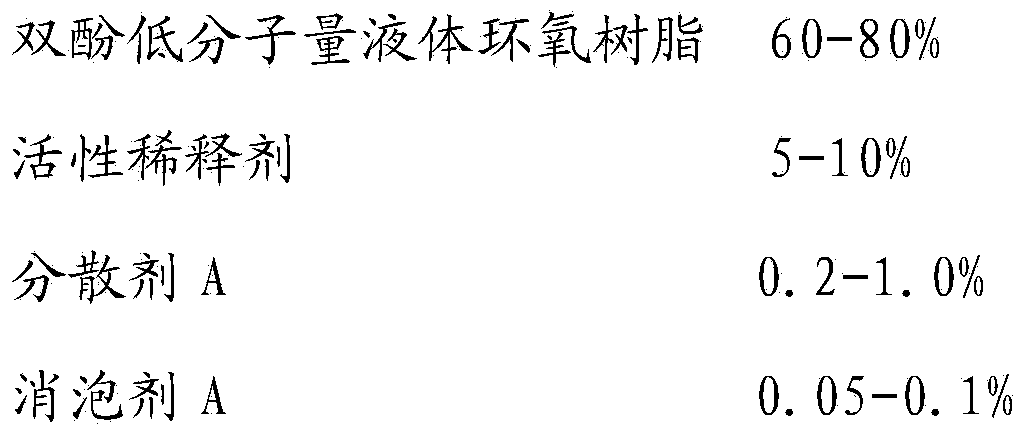

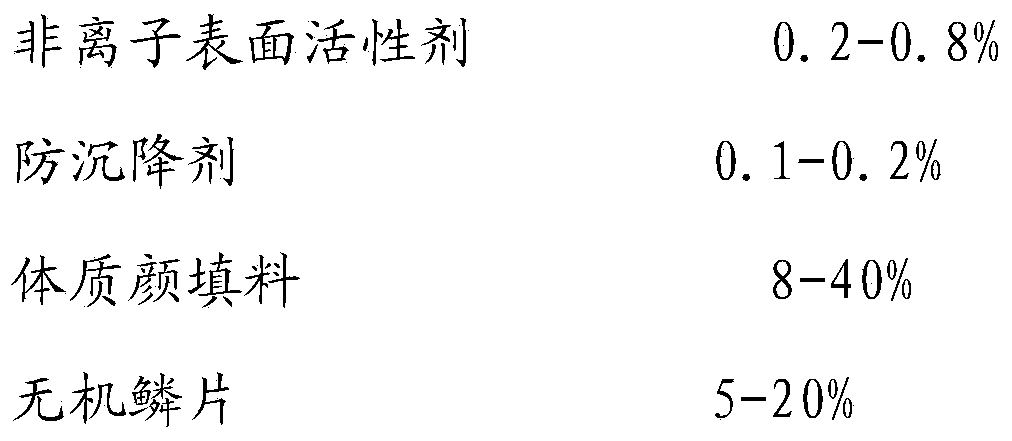

[0050] After the surface of the substrate layer is cleaned, leveled and dried, a moisture-proof surface layer is formed: first coat the substrate layer with an inorganic scale water-based epoxy resin coating, and then coat it after...

Embodiment 2

[0072] A sales center is being renovated, and wallpaper is selected as the decorative surface layer. The interior building envelope (especially the building exterior wall envelope) is coated with inorganic scale water-based epoxy resin coating on the base layer of the moisture-proof parts to form a moisture-proof structure. surface layer, and then apply putty and paste wallpaper on the moisture-proof surface layer.

[0073] The moisture-proof structure of the indoor wall of the building in this embodiment is composed of a substrate layer made of concrete or cement mortar, a moisture-proof surface layer, and a wallpaper decoration layer. The specific formation process is as follows:

[0074] After the surface of the substrate layer is cleaned, leveled and dried, a moisture-proof surface layer is formed: first coat the substrate layer with an inorganic scale water-based epoxy resin coating, and then coat it after the coating is completely cured and dried. One or more coats of in...

Embodiment 3

[0094]Partial wall decoration inside a villa, wooden decorative panels are selected as the decorative surface layer, and solid wood door frames are also used for kitchen and bathroom door frames. Inorganic flake water-based epoxy resin paint is applied to form a moisture-proof surface layer. In addition, this paint is also used to paint the surface of the wooden keel on the wall, and the decorative panel is directly laid without laying a moisture-proof film structure.

[0095] The moisture-proof structure of the indoor wall of the building in this embodiment is composed of a base material layer composed of concrete or cement mortar, a moisture-proof surface layer, and a decorative layer of a wall decorative board. The specific formation process is as follows:

[0096] 1) Form the base material layer: install and fix the embedded parts of the decorative board on the design part of the wall in advance, and then use cement mortar to level the wall surface; The substrate layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com