Organic electroluminescent device and preparation method

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of light loss, poor refractive index, low light performance, etc., to reduce total emission and improve Light efficiency, avoiding the effect of total reflection phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

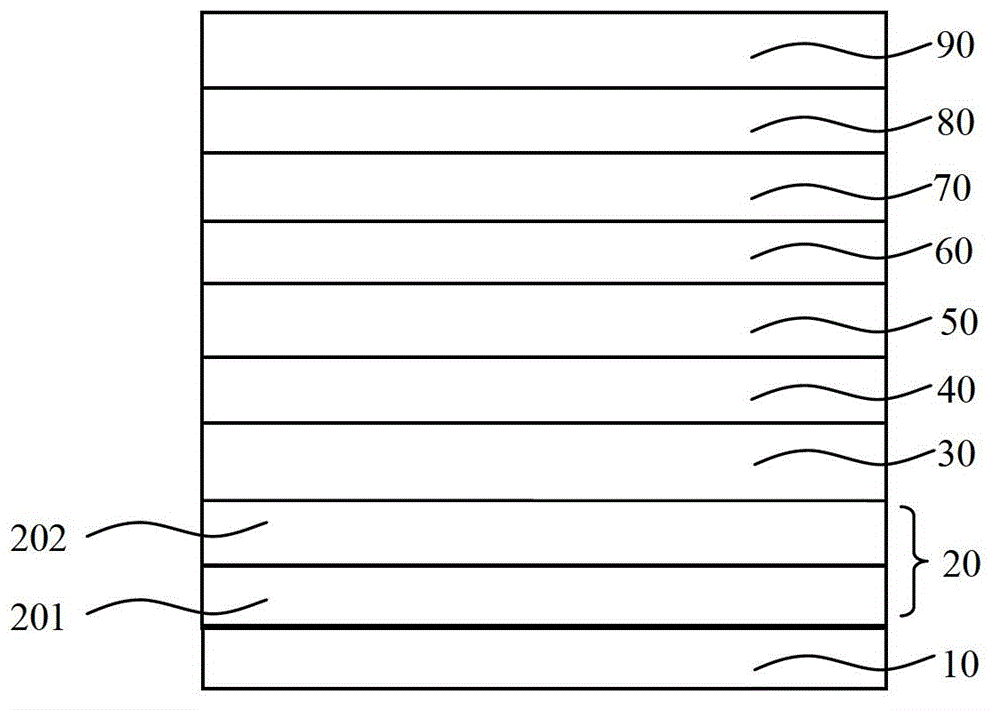

[0099] A method for preparing an organic electroluminescent device, comprising the following steps:

[0100] (1) After rinsing the N-LASF44 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0101] (2) In the high-vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), carbon aerogel with a particle size of 20nm was added to the PEDOT:PSS aqueous solution at a mass fraction of 15% to obtain a mixed solution, which was mixed at a speed of 3000rpm The mixed solution was spin-coated for 20 s on a clean glass substrate, and then dried at 100 °C for 30 min to obtain a carbon airgel layer with a thickness of 25 μm. The mass fraction of PEDOT in the PEDOT:PSS aqueous solution was 3.5%, and PEDOT and The mass ratio of PSS is 3:1;

[0102] ZnO with a particle size of 80nm is placed on the carbon airgel layer by electron beam evaporation to obtain a zinc oxide layer with a thickness of 100nm, wh...

Embodiment 2

[0112] A method for preparing an organic electroluminescent device, comprising the following steps:

[0113] (1) After rinsing the N-LAF36 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0114] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), carbon airgel with a particle size of 10nm was added to the PEDOT:PSS aqueous solution at a mass fraction of 20% to obtain a mixed solution, which was mixed at a speed of 2000rpm. The mixed solution was spin-coated for 10 s on a clean glass substrate, and then dried at 50 °C for 40 min to obtain a carbon airgel layer with a thickness of 30 μm. The mass fraction of PEDOT in the PEDOT:PSS aqueous solution was 1%, and PEDOT and The mass ratio of PSS is 2:1;

[0115] ZnO with a particle size of 200nm is placed on the carbon airgel layer by electron beam evaporation to obtain a zinc oxide layer with a thickness of 20nm, wherei...

Embodiment 3

[0121] A method for preparing an organic electroluminescent device, comprising the following steps:

[0122] (1) After rinsing the N-LASF31A glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0123] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), carbon airgel with a particle size of 100nm was added to the PEDOT:PSS aqueous solution at a mass fraction of 1% to obtain a mixed solution, which was mixed at a speed of 6000rpm The mixed solution was spin-coated for 60 s on a clean glass substrate, and then dried at 200 °C for 15 min to obtain a carbon airgel layer with a thickness of 10 μm. The mass fraction of PEDOT in the PEDOT:PSS aqueous solution was 5%, and PEDOT and The mass ratio of PSS is 6:1;

[0124] ZnO with a particle size of 50nm is placed on the carbon airgel layer by electron beam evaporation to obtain a zinc oxide layer with a thickness of 200nm, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com