Organic composite substrate for oilseed rape tray-soilless seedling and preparation method thereof

A technology for raising seedlings with composite substrates and plug trays, which is applied in the field of agricultural cultivation, can solve problems such as organic composite seedling raising substrates for vegetables that have not yet been seen, and achieve the effects of promoting large-scale promotion, reducing production costs, and realizing safe overwintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

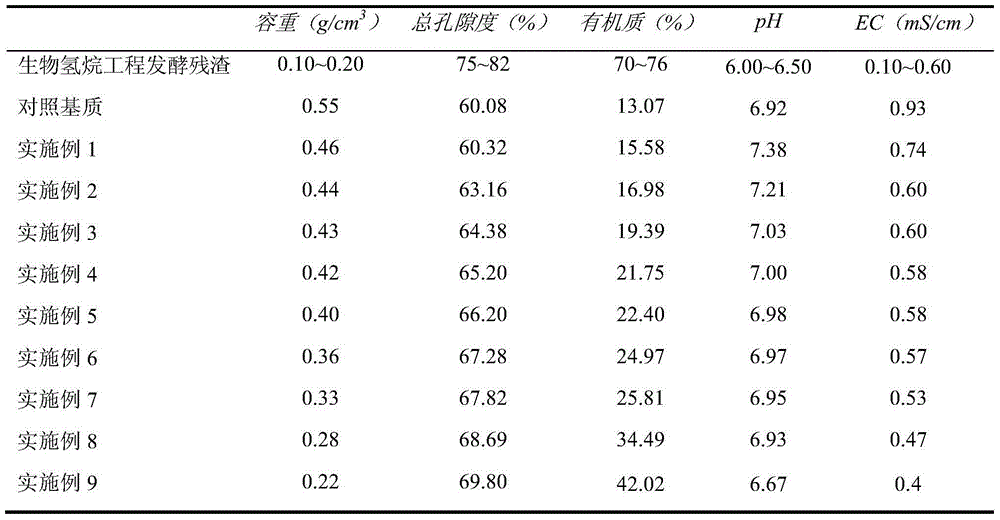

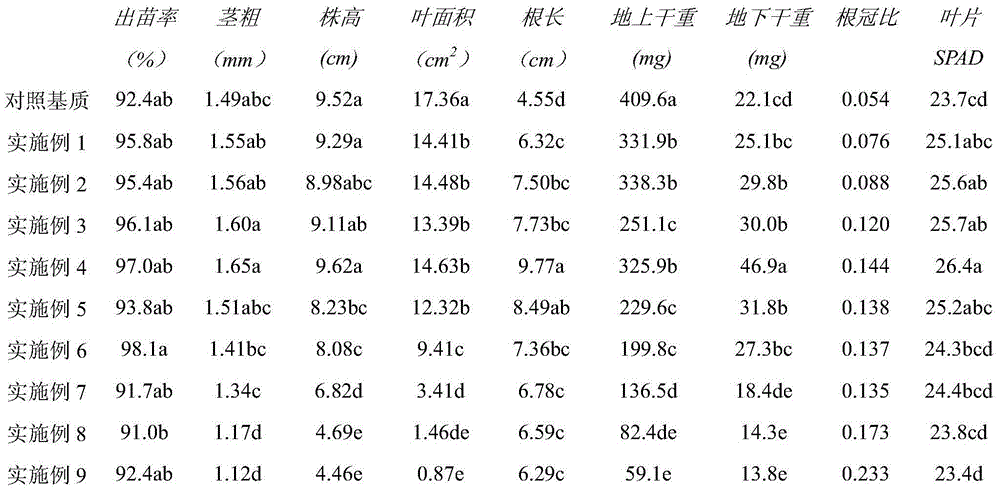

[0037] Embodiment 1 The preparation of organic composite matrix 1

[0038] (1) Preparation and treatment of residues from biohydrocarbon engineering: separate the residue and fermentation liquid from corn straw fermented and decomposed in the hydrogen production stage of biohydrocarbon engineering; air-dry and pulverize the separated fermentation residue for later use .

[0039] The weight range of each component in the treated fermentation residue is 70-76 parts of organic matter, 25-30 parts of humic acid, 44-49 parts of total carbon, 0.8-1.5 parts of total nitrogen, 0.5-1.0 parts of total phosphorus, and 0.5 parts of total potassium ~1.0 parts, total calcium 0.15~0.23 parts, total magnesium 0.05~0.1 parts, C / N is 45~55, and also contains rich trace elements such as iron, manganese, zinc, copper, boron and molybdenum. The content of heavy metal elements cadmium, chromium, lead, mercury and arsenic is within the safe use range, which meets the requirements of NY525-2011 "Org...

Embodiment 2

[0042] Example 2 Preparation of Organic Composite Matrix 1

[0043] (1) Preparation and treatment of biohydroane engineering residue: same as in Example 1.

[0044] (2) Preparation of organic composite matrix: the steps are the same as in Example 1, except that the volume ratio of fermentation residue to peat, vermiculite and perlite is 0.6:1.4:1:1.

[0045] When in use, the organic composite substrate is introduced into the seedling raising tray of the seedbed, sprayed with water, and the seeds can be directly sown.

Embodiment 3

[0046] Example 3 Preparation of Organic Composite Matrix 1

[0047] (1) Preparation and treatment of biohydroane engineering residue: same as in Example 1.

[0048] (2) Preparation of organic composite matrix: the steps are the same as in Example 1, except that the volume ratio of fermentation residue to peat, vermiculite and perlite is 0.7:1.3:1:1.

[0049] When in use, the organic composite substrate is introduced into the seedling raising tray of the seedbed, sprayed with water, and the seeds can be directly sown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com