Sludge multi-effect drying incineration treatment system and application method thereof

A treatment system and sludge technology, applied in combustion methods, dewatering/drying/concentrating sludge treatment, incinerators, etc., can solve the problems of difficult treatment cost of odorous flue gas, low production capacity, difficulty in large-scale, etc. The effect of drying energy saving, high drying efficiency and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

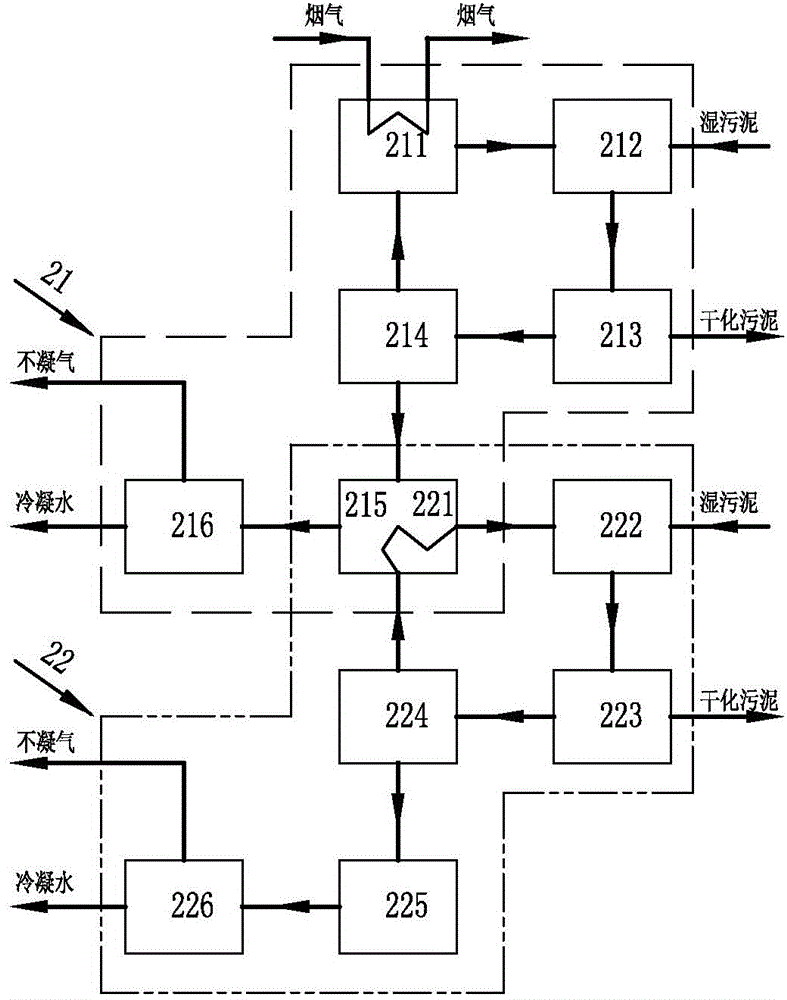

[0092] In this embodiment, the combined drying system adopts a 2-stage air-flow bed drying subsystem to dry the sludge and then incinerate it.

[0093] The process flow is connected as follows:

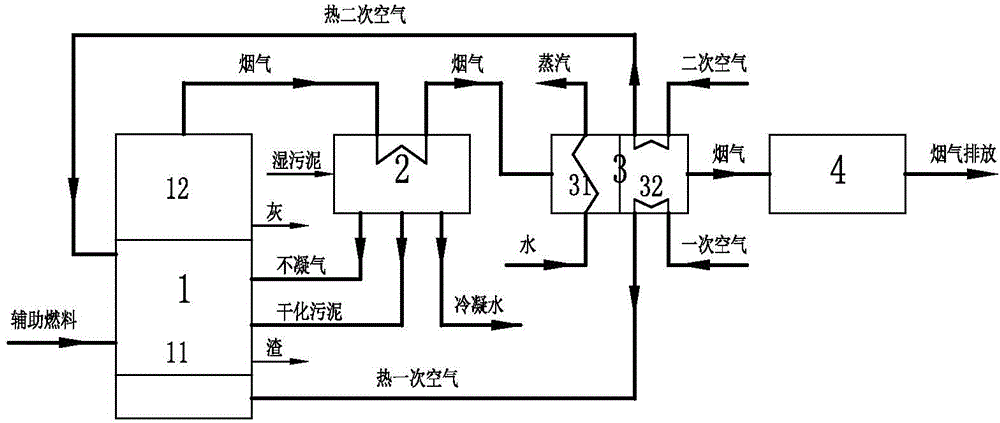

[0094] See figure 1 , figure 2 : Including an incineration system 1, a combined drying system 2, a flue gas waste heat recovery system 3, and a flue gas treatment and discharge system 4. The incineration system 1 includes a fluidized bed incinerator 11 and a high-temperature dust collector 12; the flue gas waste heat recovery system 3 includes a steam boiler 31 and an air preheater 32;

[0095] In this embodiment, the combined drying system 2 is composed of two-stage air-flow bed drying subsystems, the first-stage air-flow bed drying subsystem 21 and the second-stage air-flow bed drying subsystem 22 . The first-stage air-flow bed drying subsystem 21 is composed of a carrier gas heat exchanger 211, an air-flow bed dryer 212, a drying dust collector 213, a drying fan 214, a dry gas ...

Embodiment 2

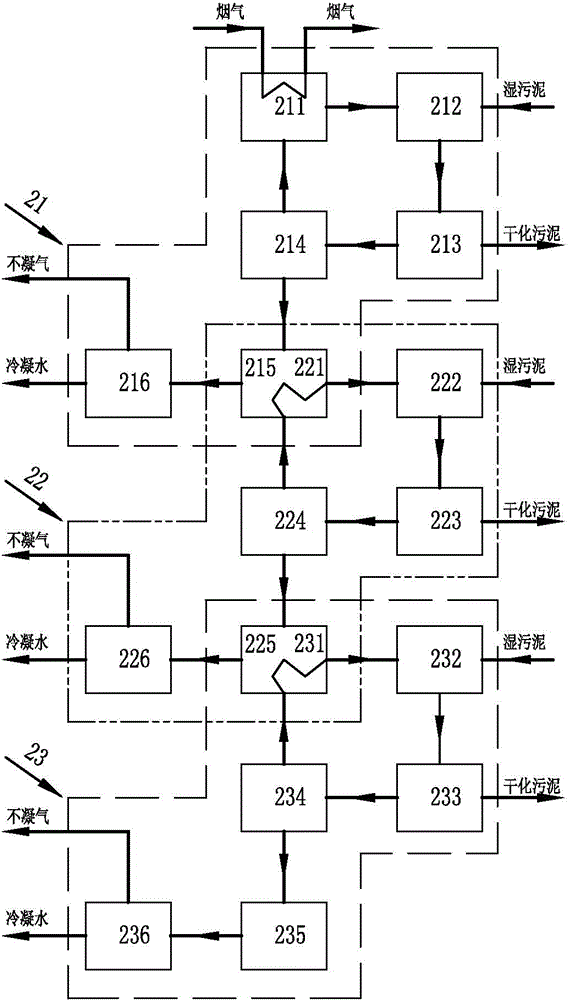

[0112] The combined drying system of this embodiment uses a 3-stage air-flow bed drying subsystem to dry the sludge and then incinerate it.

[0113] The process flow is connected as follows:

[0114] See figure 1 , image 3 : Including an incineration system 1, a combined drying system 2, a flue gas waste heat recovery system 3, and a flue gas treatment and discharge system 4. The incineration system 1 includes a fluidized bed incinerator 11 and a high-temperature dust collector 12; the flue gas waste heat recovery system 3 includes a steam boiler 31 and an air preheater 32;

[0115] In this embodiment, the combined drying system 2 is composed of three-stage air-flow bed drying subsystems, the first-stage air-flow bed drying subsystem 21 , the second-stage air-flow bed drying subsystem 22 , and the third-stage air-flow bed drying subsystem 23 .

[0116] The first-stage air-flow bed drying subsystem 21 is composed of a carrier gas heat exchanger 211, an air-flow bed dryer 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com