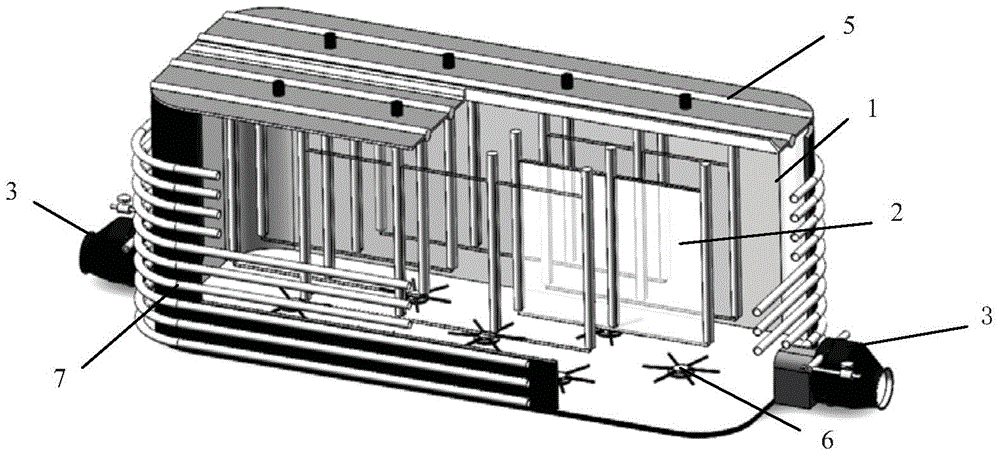

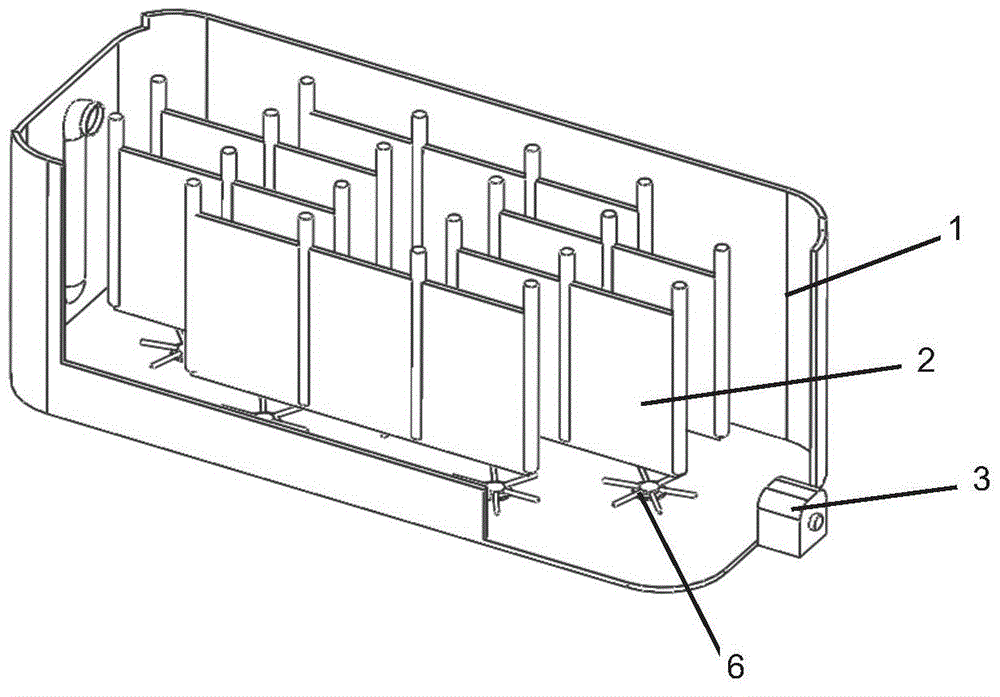

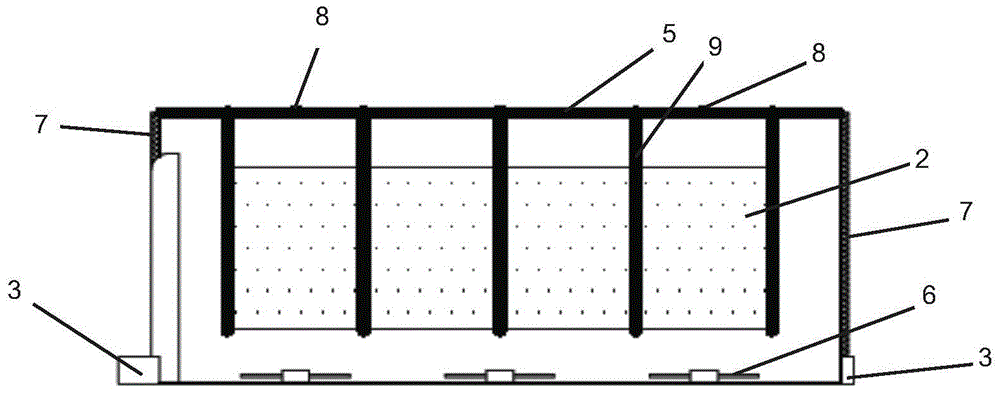

Built-in light source bioreactor and microalgae culture method

A bioreactor, built-in light source technology, applied in photobioreactor, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., can solve the problem of poor controllability, low efficiency and low degree of automation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] A conventional freshwater species of Nannochloropsis limnetica was selected, the initial culture density was 0.1g / L, and the liquid level depth of the reactor was 80cm (the cross-sectional area was 1m×1.5m). In the first stage, a red light LED with a wavelength of 706nm was used as the light source, and the temperature was kept at 24°C. Trace elements such as ammonium phosphate, zinc, and iron were added to the culture medium in advance, and a certain amount of CO was injected into the culture medium. 2 (about 90%) and NO or NO as nitrogen source 2 After waiting for nitrogen oxides for one hour, put in the algae seeds according to the initial culture density, and start the culture. After 36 hours, it was recorded that the biomass density increased to 6.86g / L (dry weight / solution, the same below), and after 72 hours, the biomass density 9.71g / L was recorded, and the microalgae in the reactor was moved to another reactor ( The depth of the liquid level is 80cm, and the c...

Embodiment 2

[0119] The freshwater species Nannochloropsis limnetica was selected, the initial culture density was 0.1g / L, and the liquid level depth of the reactor was 80cm (the cross-sectional area was 1m×1.5m). In the first stage, a blue LED with a wavelength of 450nm was used as the light source, and the temperature was kept at 24°C. Trace elements such as ammonium phosphate, zinc, and iron were added to the culture medium in advance, and a certain amount of CO was injected into the culture medium. 2 (about 90%) and NO or NO as nitrogen source 2 After waiting for nitrogen oxides for one hour, put in the algae seeds according to the initial culture density, and start the culture. After 36 hours, it was recorded that the biomass density increased to 5.66g / L, and after 72 hours, it was recorded that the biomass density was 8.03g / L. 2m×3m), stop supplying nitrogen oxides and keep CO 2 Supply, using a red LED with a wavelength of 706nm as the light source, the temperature is constant at 3...

Embodiment 3

[0122] The freshwater species of Nannochloropsis limnetica was selected, the initial culture density was 0.1g / L, and the depth of the liquid level in the reactor was 80cm (the cross-sectional area was 2m×3m). In the first stage, a red light LED with a wavelength of 706nm was used as the light source, and the temperature was kept at 24°C. Trace elements such as ammonium phosphate, zinc, and iron were added to the culture medium in advance, and a certain amount of CO was injected into the culture medium. 2 (about 90%) and NO or NO as nitrogen source 2 After waiting for nitrogen oxides for one hour, put in the algae seeds according to the initial culture density, and start the culture. Samples were taken at a certain time to measure the biomass density. Breeding ends after 144 hours.

[0123] Results: After 36 hours, the measured biomass density increased to 6.86g / L, after 72 hours, the measured biomass density was 9.91g / L, after 108 hours, the measured biomass density was 12.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com