Nitrogen-containing stainless bearing steel and preparation method thereof

A bearing steel, weight percentage technology, applied in the field of stainless steel, can solve the problems of high bearing alloy materials and processing costs, affecting surface quality and machining accuracy, affecting bearing service life, etc., to improve tempering stability and wear resistance. High performance, high machining accuracy, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

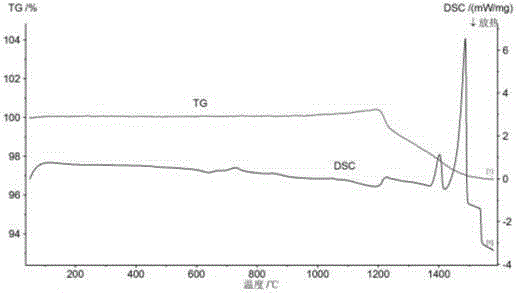

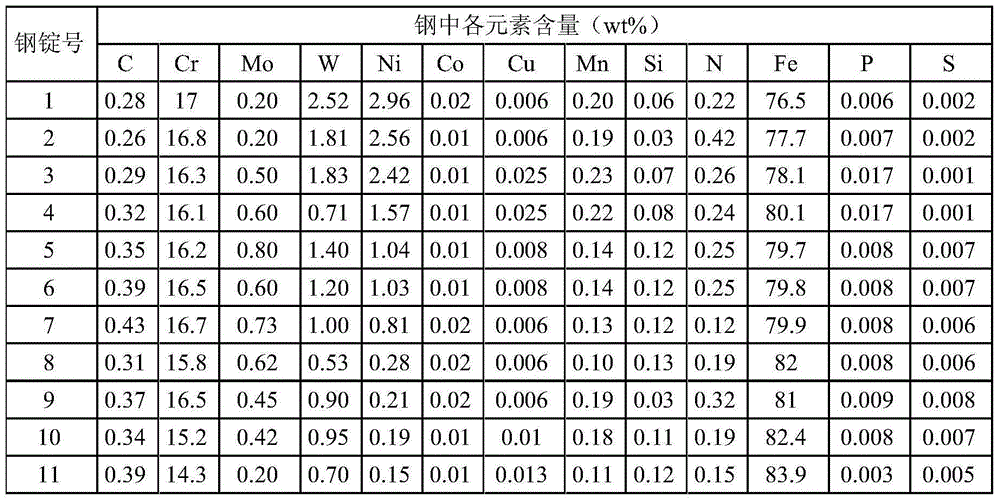

[0035] The nitrogen-containing stainless bearing steel component and content of the present invention are as shown in table 1:

[0036] Table 1 Component content of nitrogen-containing stainless bearing steel

[0037]

[0038] The above-mentioned nitrogen-containing stainless bearing steel is prepared according to the following method:

[0039] 1) Vacuum induction furnace melting

[0040] Put Fe, Cr, and W in a vacuum induction furnace according to the above ratio and refine at a high temperature of 1550-1650°C for 20-40 minutes, then add C to melt, add FeCrN under nitrogen protection, and refine at a relatively low temperature of 1480-1550°C for 10-20 minutes Minutes later, it is cast into an electroslag electrode rod;

[0041] 2) Electroslag remelting

[0042] with CaF 2 、Al 2 o 3 , CaO and MgO as the slag material, the weight percentage of each component of the slag material: CaF 2 65-68%, Al 2 o 3 12-20% for CaO, 10% for CaO, and 5-13% for MgO. Heat the slag mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com