Method for the purification of alpha-alumina fibers

An oxide and oxygen separation technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, aluminate/alumina/aluminum hydroxide purification, etc., can solve problems such as incomplete removal of metal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1: α-Al 2 O 3 Preparation of whiskers

[0068] α-Al was prepared by placing 99.9 wt% pure aluminum wires (diameter 4 mm, length 1 cm) on a powder bed 2 o 3 whiskers. The powder on the powder bed comprises quartz sand, with additional metals (or metal oxides) of various percentages of transition metals (eg, Ni, Fe, or Co). The metals used are in powder form or in the form of small flakes (spheres, etc.), while the metal oxides used are generally fine powders (<63 μm). The programmed temperature cycle used consisted of an initial ramp rate of 10 °C / min to plateau temperature, a hold of 2 hours to 4 hours, and then cooling of the system to room temperature at a rate of 10 °C / min. The platform temperature was maintained at 1300°C to 1600°C, but a temperature of 1550°C was used most of the time. A furnace with an inner atmosphere of argon was used and an argon flux of 0.2 L / min was maintained during the ramp up and ramp down steps. During the constant...

Embodiment 2

[0069] Example 2: α-Al 2 O 3 Purification of whiskers

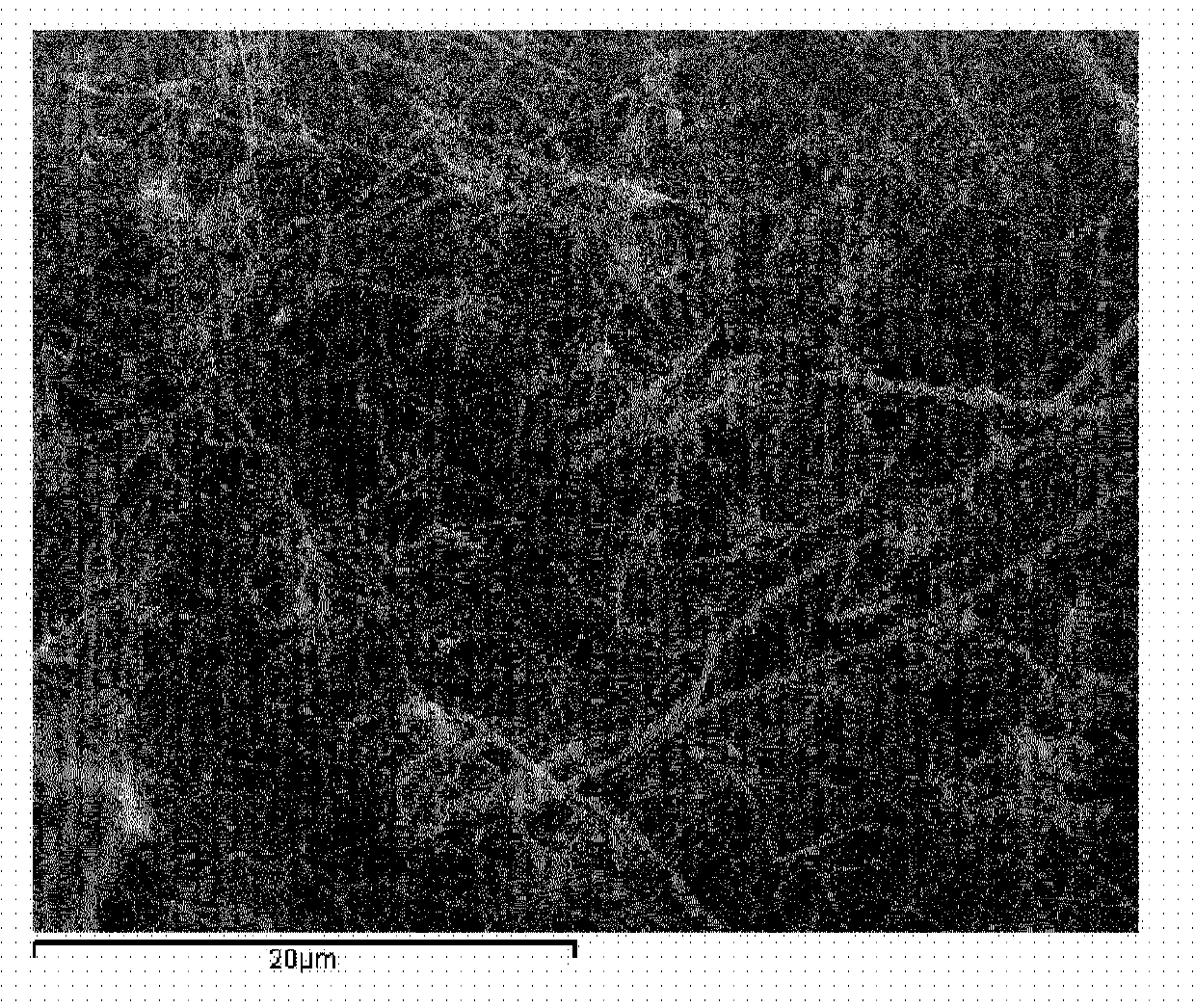

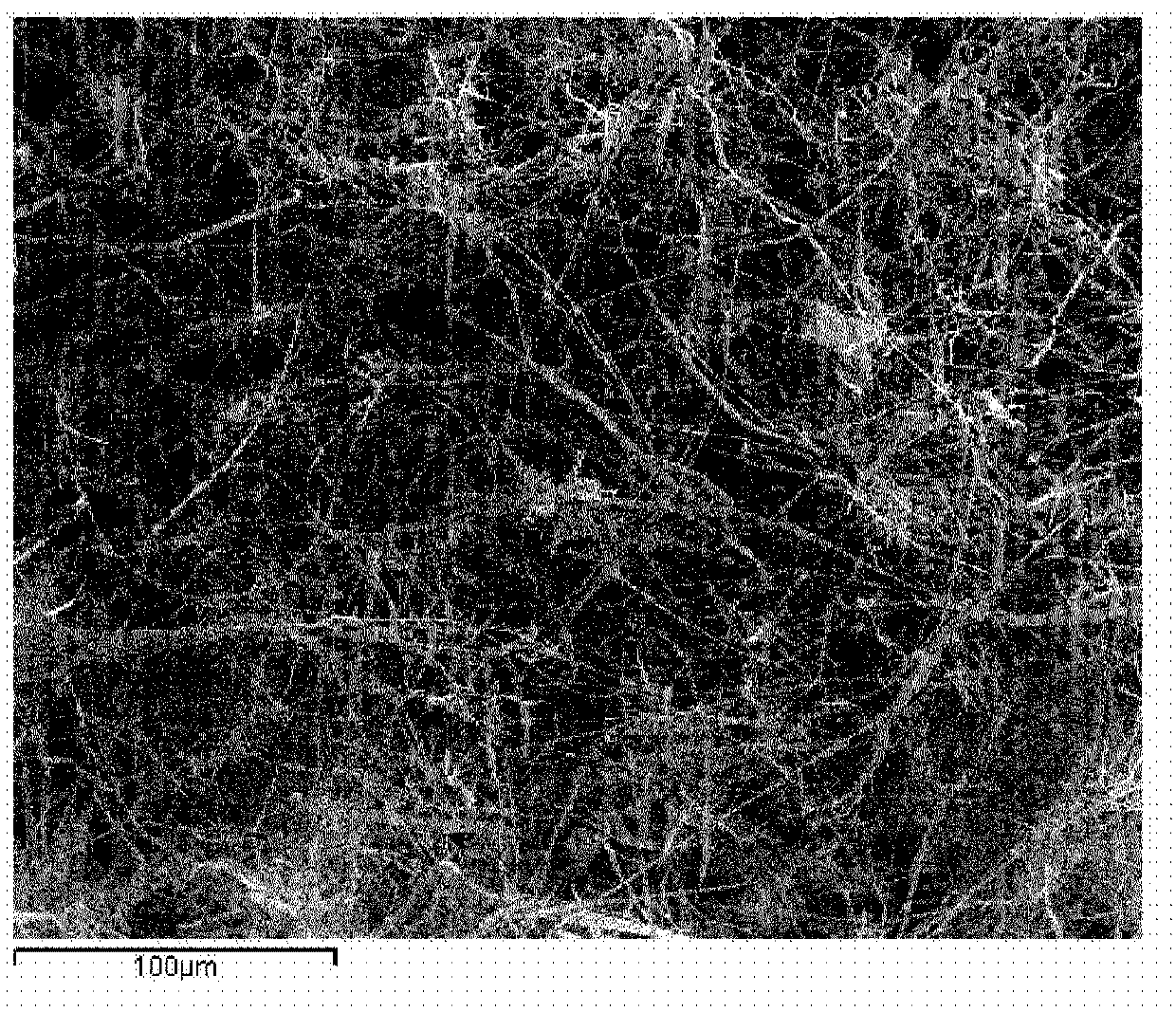

[0070] Fibers with an average size of 0.5 μm in diameter and 100 μm to 1 mm in length were placed on 4 alumina ceramic discs measuring 15 x 15 x 1 cm. They are then introduced into the interior of the oven chamber and stacked on top of each other with the aid of aluminum oxide supports. Next, close the furnace and make it airtight by vacuum to achieve 6×10 -2 oxygen partial pressure atm. Then, a programmed temperature cycle was started with an initial heating rate of 5 °C / min to a plateau temperature of 1650 °C for 2 hours, after which the system was cooled to room temperature.

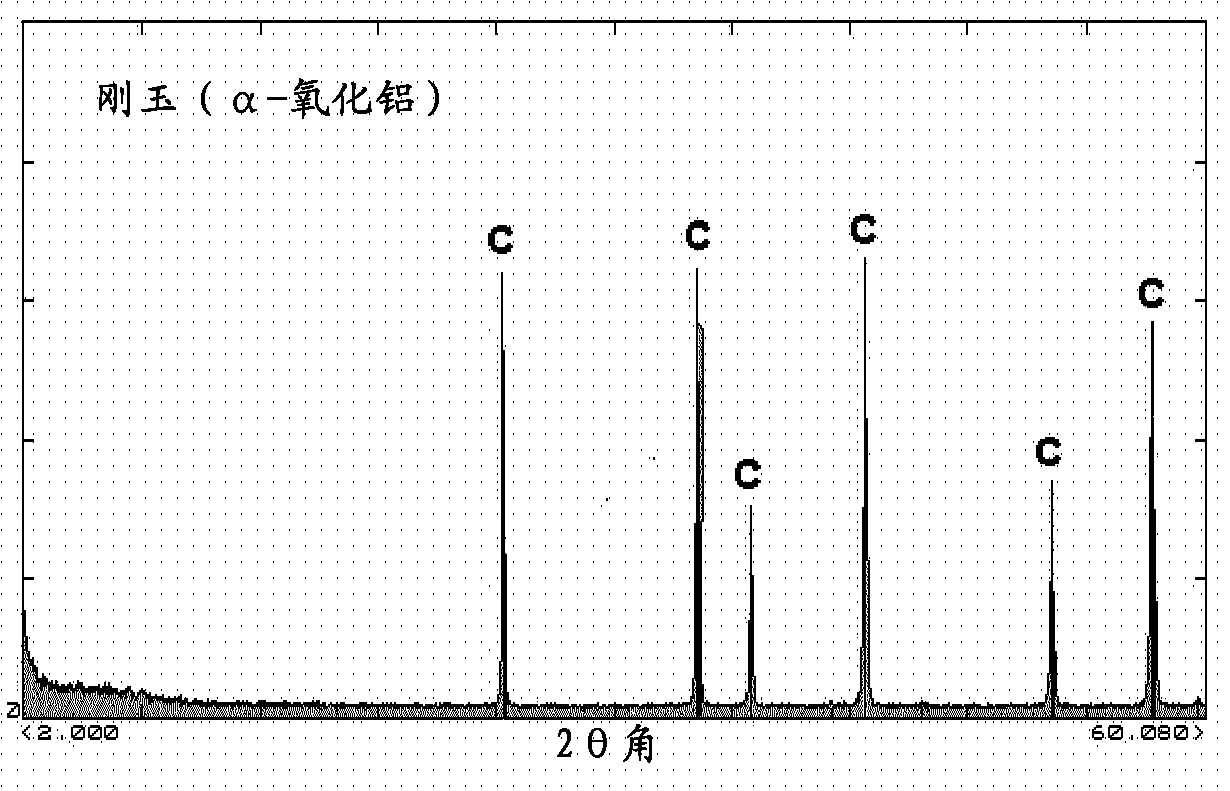

[0071] The purified alumina whiskers were characterized by X-ray diffraction, and this analysis revealed that the only crystalline phase present was the corundum or α-alumina phase ( figure 1 ). Analysis by chemical analysis ICP showed alumina fibers with a purity higher than 99.97%, due to the almost complete removal of transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com