Preparation method of water-chestnut fermented beverage

A technology of fermented beverages and horseshoes, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve problems such as lack of clear instructions, restrictions on the development of horseshoe products, complex processes, etc., to reduce the amount of enzymes used, The effect of reducing processing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

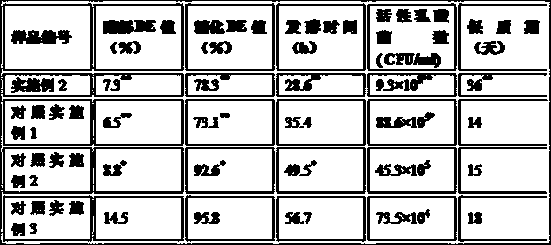

Examples

Embodiment 1

[0030] Take fresh horseshoes, wash them three times with running water, and then treat them at 15MPa in an ultra-high pressure treatment device for 45 minutes; crush the horseshoes after ultra-high pressure treatment, add water 3-5 times the weight of raw materials for grinding; then add to the slurry Add 4U / g of α-amylase and 2U / g of isoamylase, enzymatically hydrolyze at 85°C for 40 minutes, add 80U / g of glucoamylase after inactivation, and perform enzymatic hydrolysis at 75°C for 120min for saccharification, after saccharification, inactivate the enzyme. Then add bifidobacteria and lactic acid bacteria mixed at a ratio of 1:1 to the saccharification solution after enzyme inactivation, the inoculum amount is 3.5%, and ferment at 42°C until the acidity is 70 0 T. Homogenize the fermented raw materials for 3 times at room temperature of 20Mpa, and directly seal and pack in cans after homogenization.

Embodiment 2

[0032]Take fresh horseshoes, wash them three times with running water, and then treat them at 20MPa in an ultra-high pressure treatment device for 30 minutes; crush the horseshoes after ultra-high pressure treatment, add water 3-5 times the weight of raw materials for grinding; then add to the slurry Add 6U / g of α-amylase and 1U / g of isoamylase, enzymatically hydrolyze at 85°C for 45min, add 120U / g of glucoamylase after enzymatic hydrolysis at 85°C for 60min for saccharification, and inactivate the enzyme after saccharification. Then add bifidobacteria and lactic acid bacteria mixed at a ratio of 1:2 to the saccharification solution after enzyme inactivation, the inoculum amount is 5%, and ferment at 42°C until the acidity is 70 0 T. The fermented raw materials are homogenized twice at room temperature of 25Mpa, and directly sealed and packed in cans after homogenization.

Embodiment 3

[0034] Take fresh horseshoes, wash them three times with running water, and then treat them in an ultra-high pressure treatment device at 25MPa for 20 minutes; crush the horseshoes after ultra-high pressure treatment, add water 3-5 times the weight of raw materials for grinding; then add to the slurry Add 5U / g of α-amylase and 3U / g of isoamylase, enzymatically hydrolyze at 85°C for 30min, add 100U / g of glucoamylase after enzymatic hydrolysis at 85°C for 90min for saccharification, and inactivate the enzyme after saccharification. Then add bifidobacteria and lactic acid bacteria mixed at a ratio of 1.5:1 to the saccharification solution after enzyme inactivation, the inoculum amount is 4%, and ferment at 42°C until the acidity is 70 0 T. Homogenize the fermented raw materials once at room temperature of 30Mpa, and directly seal and pack them in cans after homogenization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com