Method for preparing copper-based catalyst

A copper-based catalyst, chloride technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the complicated operation, prolonged catalyst preparation process, and energy consumption. Large and other problems, to achieve the effect of simple preparation process, short reaction time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

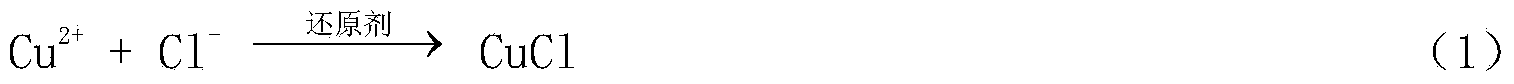

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A mixed aqueous solution made of 250g copper sulfate pentahydrate and 58.5g sodium chloride is used as a feed liquid, and is transferred into a pressure-resistant and corrosion-resistant reaction kettle. Add polyvinyl alcohol and glucose 18g, the mass ratio of polyvinyl alcohol and reducing agent glucose is 2:1, add 163.25g of copper-based catalyst carrier, after ultrasonic dispersion, transfer the material liquid into the reaction kettle, seal the kettle, seal and heat to 120°C, water Thermal reduction reaction was carried out for 7 hours to form cuprous chloride crystals, which were filtered after cooling, and the precipitate was washed with dilute hydrochloric acid and ethanol in sequence, and vacuum-dried at 70°C to obtain the target product cuprous chloride crystal catalyst.

[0044] Wherein, the preparation steps of copper-based catalyst carrier are as follows:

[0045] Weigh 20g of 200-mesh distiller's grains, carbonize with 80g of mixed acid at 20°C for 2 hours, t...

Embodiment 2

[0047] A mixed aqueous solution made of 250g copper sulfate pentahydrate and 58.5g sodium chloride is used as a feed liquid, and is transferred into a pressure-resistant and corrosion-resistant reaction kettle. Add polyethylene glycol and reducing agent glucose 30g, the mass ratio of polyethylene glycol and reducing agent glucose is 4:3, add 169.25g of copper-based catalyst carrier, after ultrasonic dispersion, transfer the material liquid into the reaction kettle, seal the kettle, and heat it tightly to 140°C, hydrothermal reduction reaction for 7 hours to produce cuprous chloride crystals, filtered after cooling, washed the precipitate with dilute hydrochloric acid and ethanol in sequence, and vacuum dried at 70°C to obtain the target product cuprous chloride crystal catalyst.

[0048] Wherein, the preparation steps of copper-based catalyst carrier are as follows:

[0049] Weigh 20g of 300-mesh distiller's grains, carbonize with 120g of mixed acid at 80°C for 12h, the ratio ...

Embodiment 3

[0051] The mixed aqueous solution made of 250g copper sulfate pentahydrate and 64g sodium chloride was used as the feed liquid, and transferred into a pressure-resistant and corrosion-resistant reaction kettle. Copper polyvinylpyrrolidine and glucose reducing agent 36g, the mass ratio of copper polyvinylpyrrolidine and glucose reducing agent is 1:1, add 175g copper-based catalyst carrier, after ultrasonic dispersion, transfer the material liquid into the reaction kettle, seal the kettle, and seal it tightly Heating to 140°C, hydrothermal reduction reaction for 8 hours, forming cuprous chloride crystals, filtering after cooling, washing the precipitate with dilute hydrochloric acid and ethanol in sequence, and vacuum drying at 70°C to obtain the target product cuprous chloride crystal catalyst.

[0052] Wherein, the preparation steps of copper-based catalyst carrier are as follows:

[0053] Weigh 20g of 250-mesh distiller's grains, carbonize with 100g of mixed acid at 80°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com