a mos 2 Controllable Synthesis and Simultaneous Surface Modification of Nanosheets

A nanosheet, mixed solvent technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of controllable synthesis and surface PEG modification of MoS2 nanosheets that have not yet been developed, and the inability to achieve nanosheet shape. appearance, complex process and other problems, to achieve good blood compatibility and biocompatibility, improve biocompatibility, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

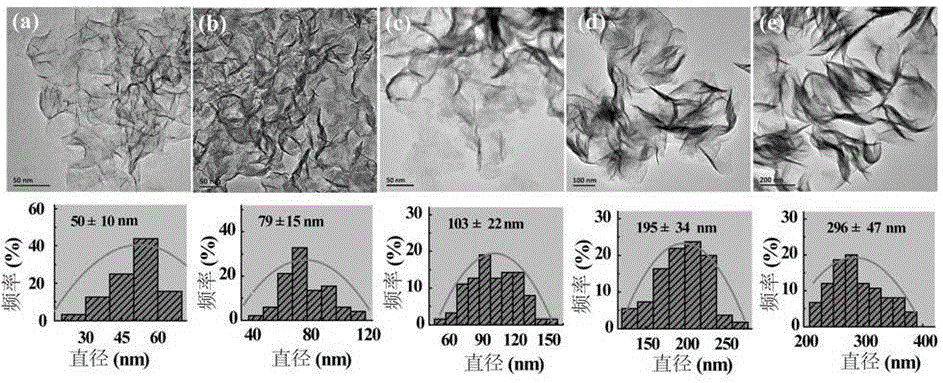

[0064] Weigh 0.3 g of ammonium tetrathiomolybdate (purchased from Changsha Jingkang New Material Technology Co., Ltd.), mix with 60 mL of distilled water, and stir at room temperature for 1 h to obtain a clear and transparent solution. The resulting solution was transferred to a 100 mL volume stainless steel reaction kettle lined with p-polyphenylene and sealed. Put the reaction kettle into a high-temperature oven for heat treatment at 220°C for 12 hours. After naturally cooling to room temperature, the reaction mixture was centrifuged and washed 5 times with 50% ethanolamine solution and distilled water to obtain MoS 2 Nanosheets. TEM observation results ( figure 1 In a) shows that the resulting MoS 2 Presents an irregular lamellar structure. Using Image J 1.40G software (http: / / rsb.info.nih.gov / ij / download.html, National Institutes of Health, USA) to measure the diameter of nanosheets (measure at least 50 sheets), MoS 2 The diameter of the lamellae is 50±10 nm.

Embodiment 2

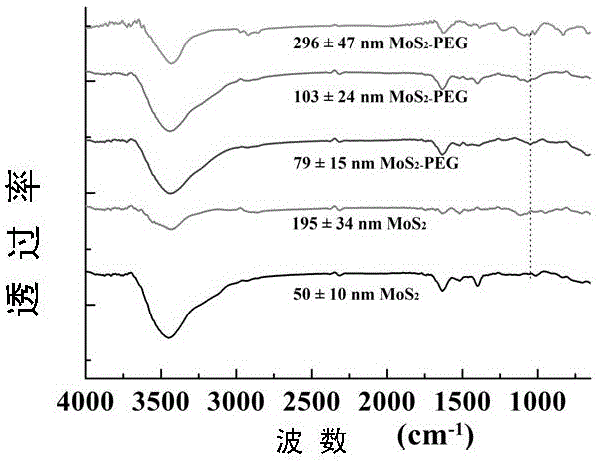

[0066] Weigh 0.3 g of ammonium tetrathiomolybdate (purchased from Changsha Jingkang New Material Technology Co., Ltd.), mix with 30 mL of distilled water, and stir at room temperature for 1 h to obtain a clear and transparent solution. Then, 30 mL PEG400 (Shanghai Sinopharm Chemical Reagent Co., Ltd.) was added to the above solution, and stirring was continued at room temperature for 1 h. The resulting solution was transferred to a 100 mL volume stainless steel reaction kettle lined with p-polyphenylene and sealed. Put the reaction kettle into a high-temperature oven for heat treatment at 220°C for 12 hours. After naturally cooling to room temperature, the reaction mixture was centrifuged and washed 5 times with 50% ethanolamine solution and distilled water to obtain MoS 2 - PEG nanosheets. TEM observation results ( figure 1 b) shows that the resulting MoS 2 It presents an irregular lamellar structure with a lamellar diameter of 79±15nm. FTIR results ( figure 2 ) indicat...

Embodiment 3

[0068] Weigh 0.15 g of ammonium tetrathiomolybdate (purchased from Changsha Jingkang New Material Technology Co., Ltd.), mix with 30 mL of distilled water, and stir at room temperature for 1 h to obtain a clear and transparent solution. Then, 30 mL PEG400 (Shanghai Sinopharm Chemical Reagent Co., Ltd.) was added to the above solution, and stirring was continued at room temperature for 1 h. The resulting solution was transferred to a 100 mL volume stainless steel reaction kettle lined with p-polyphenylene and sealed. Put the reactor into a high-temperature oven for heat treatment at 220°C for 12 hours. After cooling to room temperature naturally, the reaction mixture was centrifuged and washed 5 times with 50% ethanolamine solution and distilled water to obtain MoS 2 - PEG nanosheets. TEM observation results ( figure 1 In c) shows that the obtained MoS 2 -PEG presents an irregular lamellar structure with a lamellar diameter of 103±22nm. FTIR results ( figure 2 ) indicates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com