Corrosive liquid for tellurium-cadmium-mercury material and preparation method of corrosive liquid

A preparation method and mercury cadmium telluride technology are applied in the field of manufacturing technology of mercury cadmium telluride detector chips, which can solve the problems of high purity requirements of hydrobromic acid and strict requirements on the temperature range of corrosive environment, and achieve a large viscosity coefficient and high reliability. The effect of controlling corrosion and reducing corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Immerse the mercury cadmium telluride material to be corroded successively in MOS-grade trichlorethylene, ether, acetone, and alcohol for 10 minutes, and dry it with nitrogen after cleaning;

[0015] 2. Set the speed of the KW-4 homogenizer to 2000r / min, and the rotation time to 30s. Spin-coat a layer of photoresist on the surface of the HgCdTe material, and then bake it in an oven at 80 degrees Celsius for 30 minutes;

[0016] 3. Select a tabletop photolithography plate, use MJB3 photolithography machine to lithography, expose for 7s, develop for 10s, fix with deionized water, and bake in an oven at 80 degrees Celsius for 30 minutes;

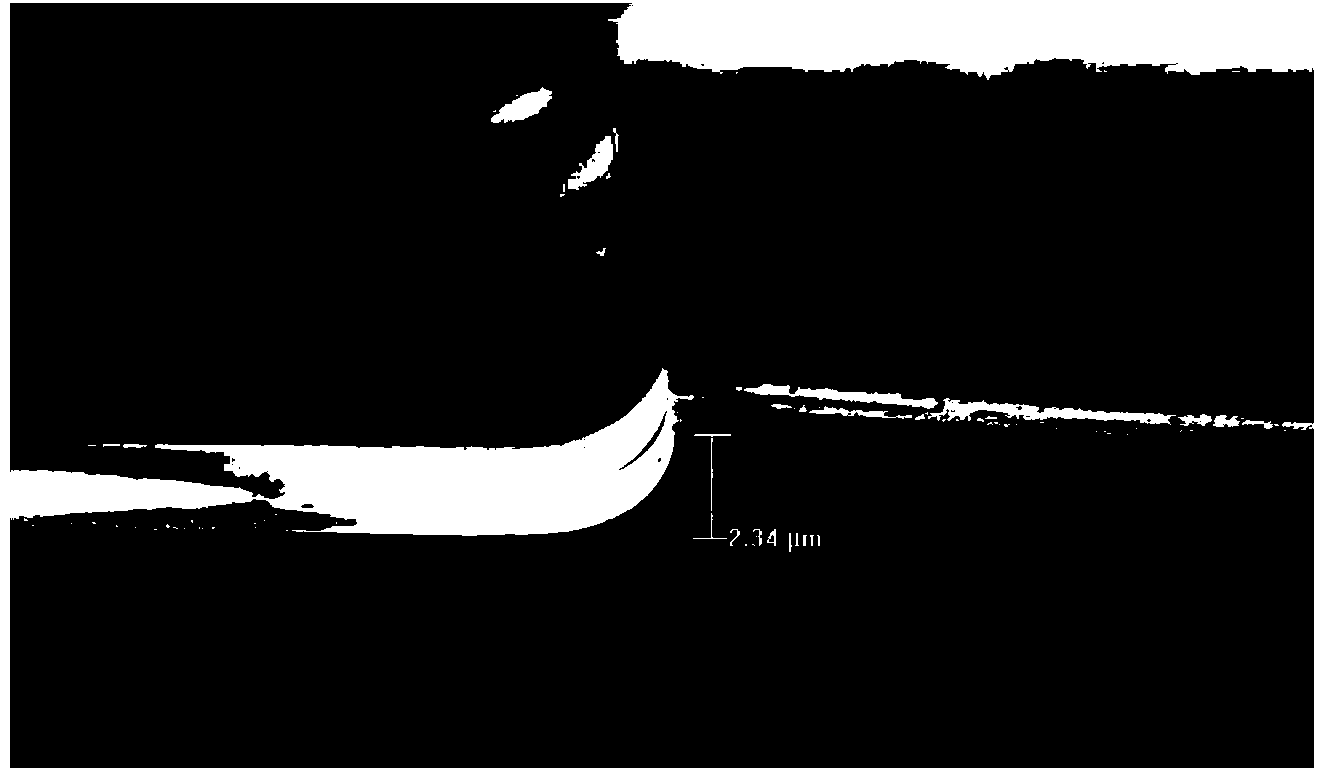

[0017] 4. Prepare HgCdTe material corrosion solution, the volume ratio is bromine: hydrobromic acid: ethylene glycol = 1:5:50. First pour the hydrobromic acid solution into the ethylene glycol solution in proportion, let it stand for 10 minutes, then pour the bromine solution into the mixed solution of hydrobromic acid and ethylene gl...

Embodiment 2

[0020] 1. Immerse the mercury cadmium telluride material to be corroded successively in MOS-grade trichlorethylene, ether, acetone, and alcohol for 10 minutes, and dry it with nitrogen after cleaning;

[0021] 2. Set the speed of the KW-4 homogenizer to 2000r / min, and the rotation time to 30s. Spin-coat a layer of photoresist on the surface of the HgCdTe material, and then bake it in an oven at 80 degrees Celsius for 30 minutes;

[0022] 3. Select a tabletop photolithography plate, use MJB3 photolithography machine to lithography, expose for 7s, develop for 10s, fix with deionized water, and bake in an oven at 80 degrees Celsius for 30 minutes;

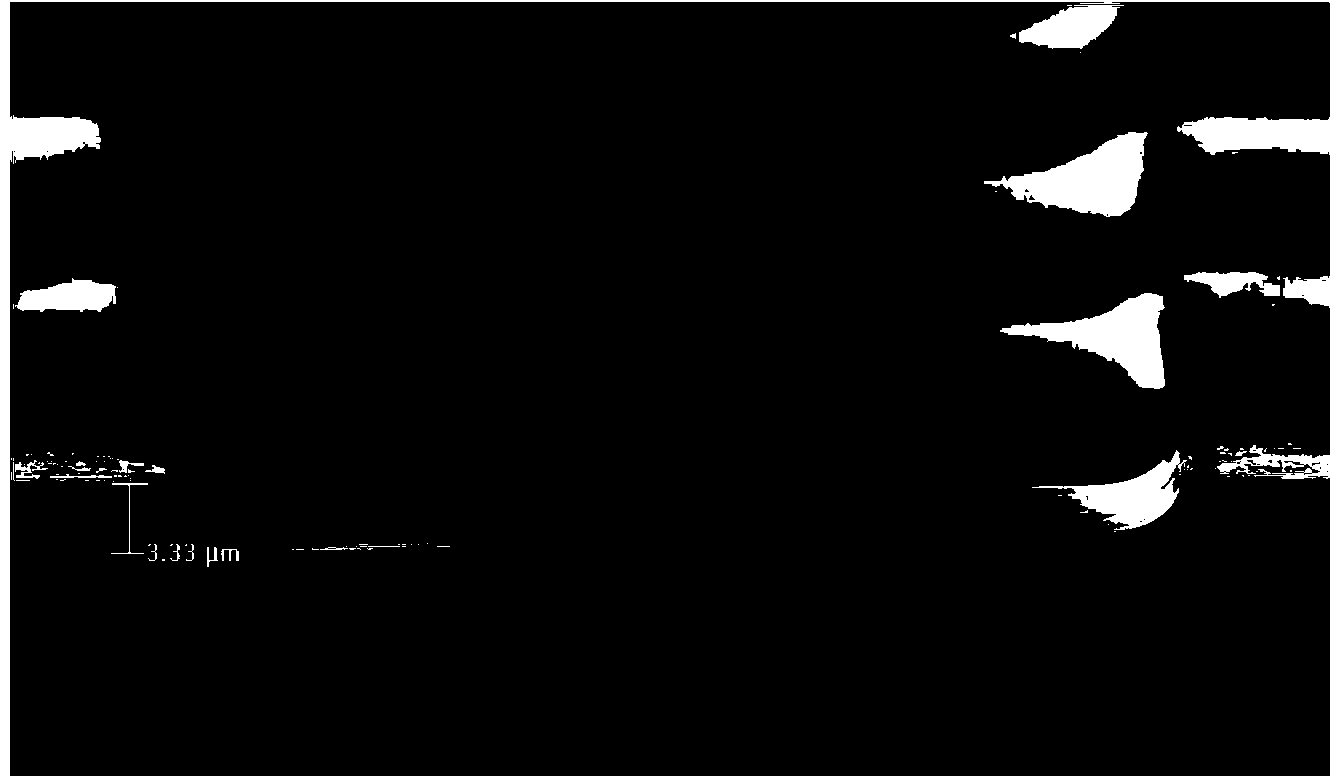

[0023] 4. Prepare HgCdTe material corrosion solution, the volume ratio is bromine: hydrobromic acid: ethylene glycol = 1:20:30. First pour the hydrobromic acid solution into the ethylene glycol solution in proportion, let it stand for 10 minutes, then pour the bromine solution into the mixed solution of hydrobromic acid and ethylene g...

Embodiment 3

[0026] 1. Immerse the mercury cadmium telluride material to be corroded successively in MOS-grade trichlorethylene, ether, acetone, and alcohol for 10 minutes, and dry it with nitrogen after cleaning;

[0027] 2. Set the speed of the KW-4 homogenizer to 2000r / min, and the rotation time to 30s. Spin-coat a layer of photoresist on the surface of the HgCdTe material, and then bake it in an oven at 80 degrees Celsius for 30 minutes;

[0028] 3. Select a tabletop photolithography plate, use MJB3 photolithography machine to lithography, expose for 7s, develop for 10s, fix with deionized water, and bake in an oven at 80 degrees Celsius for 30 minutes;

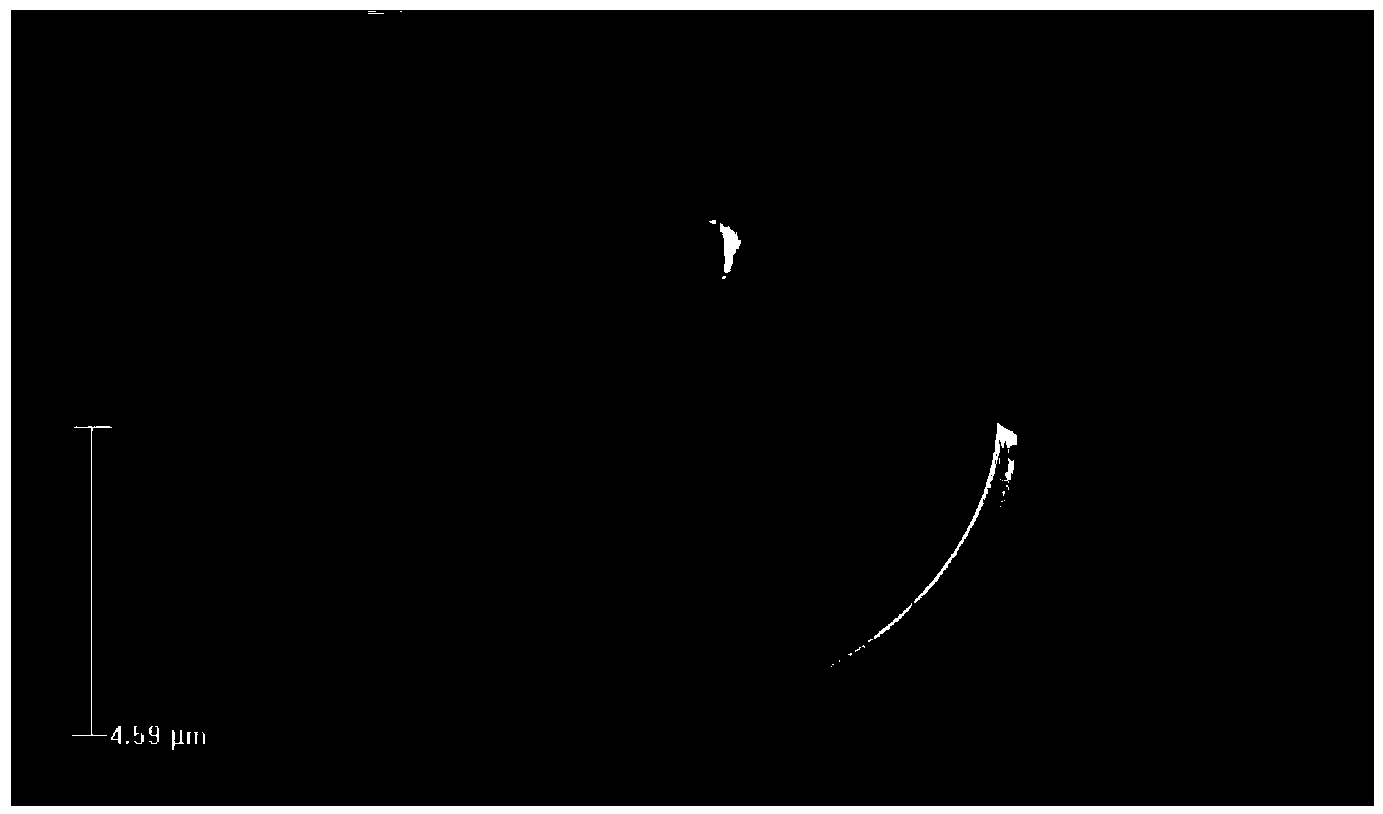

[0029] 4. Prepare HgCdTe material corrosion solution, the volume ratio is bromine: hydrobromic acid: ethylene glycol = 1:50:20. First pour the hydrobromic acid solution into the ethylene glycol solution in proportion, let it stand for 10 minutes, then pour the bromine solution into the mixed solution of hydrobromic acid and ethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com