A zno/vo 2 Composite thermal phase change material and preparation method thereof

A phase change material, thermal phase change technology, applied in the growth of polycrystalline materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of temperature-controlled devices without metal-semiconductor phase change The process is difficult to deal with, and it is difficult to solve the problems of nano-optical electronic devices, so as to achieve the effect of rich morphology, controllable morphology and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

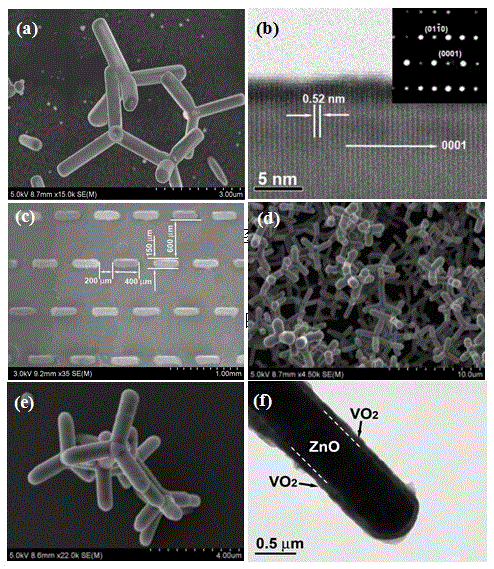

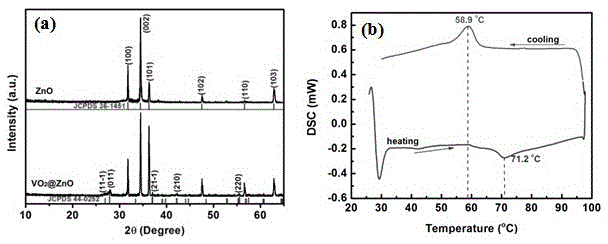

[0023] The concrete steps of this embodiment are as follows:

[0024] In the first step, ZnO powder and graphite powder are mixed and stirred at a mass ratio of 1:1, loaded into a quartz boat and placed in the center of the horizontal quartz tube furnace tube, and then the alumina substrate is placed on the horizontal tube In a type furnace, the substrate is covered with a stainless steel template, and the template is provided with holes arranged in a periodic distribution. A preferred periodic distribution of the holes is arranged in a matrix. The row spacing of the holes is 600 μm, and the column spacing is The hole is a rounded rectangular hole with a length of 400 μm and a width of 150 μm, so that a patterned template is formed, and the distance between the quartz boat and the template is 11 cm.

[0025] In the second step, the temperature at the center of the furnace tube was raised to 300°C at a rate of 10°C / min, kept for 20 minutes, and then naturally cooled to 180°C. ...

Embodiment 2

[0032] The steps of the present embodiment are the same as the steps of the above-mentioned embodiment 1, and the difference is the variation of some control quantities in the specific steps, as follows:

[0033] In the first step: a. the distance between the substrate and the quartz boat is controlled at 8cm;

[0034] In the second step: a. the temperature at the center of the furnace tube is raised to 290° C. at a rate of 8° C. / min and maintained for 25 minutes;

[0035] b. Nitrogen as a carrier gas is used to bring the central temperature of the furnace chamber to 475°C at a heating rate of 10°C / min and keep it for 35 minutes.

[0036] In the third step: a. The temperature in the vanadyl acetylacetonate storage area is controlled at 200°C; the purity is 99.999%;

[0037] b. Oxygen and nitrogen with a purity of 99.999% and a volume ratio of 8:92 are mixed to form a carrier gas, and the carrier gas is passed into the chemical vapor deposition system at a flow rate of 40ccm, ...

Embodiment 3

[0039] The steps of the present embodiment are the same as the steps of the above-mentioned embodiment 1, and the difference is the variation of some control quantities in the specific steps, as follows:

[0040] In the first step: a. the distance between the substrate and the quartz boat is controlled at 15cm;

[0041] In the second step: a. the temperature at the center of the furnace tube is raised to 310° C. at a rate of 12° C. / min and maintained for 15 minutes;

[0042] b. Feed nitrogen gas with purity and flow rate of 98.5% to 99.999% and 520 sccm respectively as carrier gas, and raise the temperature of the center of the furnace chamber to 485° C. at a heating rate of 20° C. / min and keep it for 45 minutes.

[0043] In the third step: a. The temperature in the vanadyl acetylacetonate placement area is controlled at 200°C;

[0044] b. Oxygen and nitrogen with a purity of 99.999% and a volume ratio of 11:89 are mixed to form a carrier gas, and the carrier gas is passed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com