Flake graphite composite sealing plate and manufacturing method

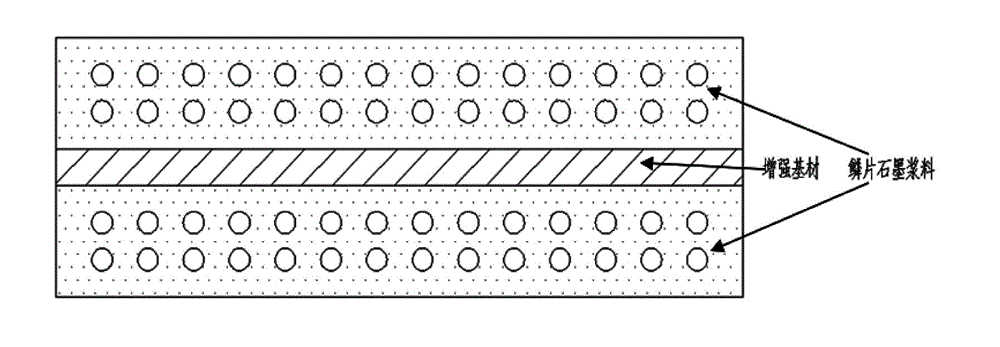

A flake graphite and composite sealing technology, which is applied in the manufacture of tools, engine seals, ceramic molding machines, etc., can solve the problems of high content of harmful elements, poor air tightness, poor forming process, etc., and achieve simple forming process and low cost. Low cost, simple and easy controllable forming process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

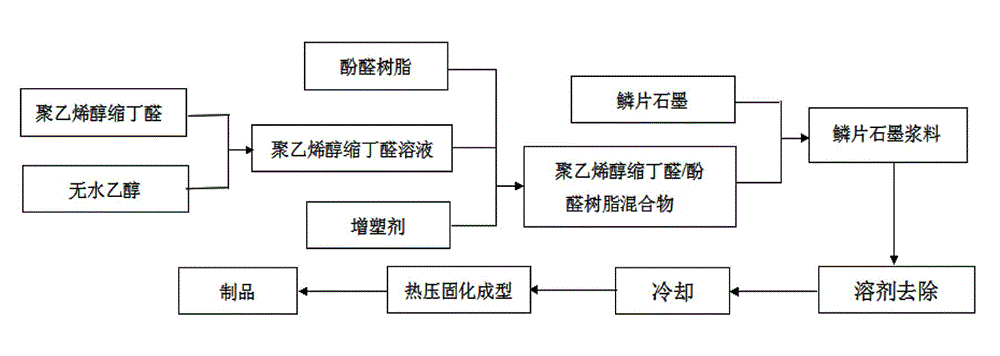

[0027] (1) Preparation of flake graphite slurry

[0028] Prepare fine flake graphite slurry with good fluidity, the mass fraction of the slurry is: 25 parts of fine flake graphite powder (this fine flake graphite powder is 200 mesh sieve), 25 parts of organic binder, plasticizer 2.4 parts, 47.6 parts of solvent.

[0029] The above organic binder is: polyvinyl butyral powder and liquid phenolic resin, the mass ratio of which is 3:1.

[0030] Above-mentioned solvent is dehydrated alcohol, and plasticizer is dibutyl phthalate.

[0031] According to the above ratio, put the polyvinyl butyral powder into the liquid absolute ethanol at a speed of 200r / min while stirring, and try to avoid forming agglomerated polyvinyl butyral (due to the formation of agglomerated After polyvinyl butyral, the dissolution time will increase several times), stir on a magnetic stirrer for 35 minutes to completely dissolve the polyvinyl butyral powder, then add liquid phenolic resin and continue for 15...

Embodiment 2

[0039] (1) Preparation of fine flake graphite slurry

[0040] Prepare fine flake graphite slurry with good fluidity. The mass fraction of the slurry consists of: 24.5 parts of fine flake graphite powder (this fine flake graphite powder is a 300 mesh sieve), 19.6 parts of organic binder, plasticizer 1.9 parts, 54 parts of solvent.

[0041] The above organic binder is: polyvinyl butyral powder and liquid phenolic resin, the mass ratio of which is 2:1.

[0042] The above-mentioned solvent is absolute ethanol and acetone, and its composition mass ratio is 3:1, and the plasticizer is dioctyl phthalate.

[0043] According to the above ratio, put polyvinyl butyral powder into absolute ethanol and acetone at an appropriate speed while stirring, and try to avoid agglomerated polyvinyl butyral (due to the formation of agglomerated polyethylene After alcohol butyral, the dissolution time will increase several times), stir on a magnetic stirrer for 30 minutes to completely dissolve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com