Preparation method of calcium, strontium and barium scale inhibitor

A technology of scale inhibitor, strontium barium, which is applied in the field of preparation of calcium strontium barium scale inhibitor, can solve the problems of narrow trial range and weak anti-scaling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

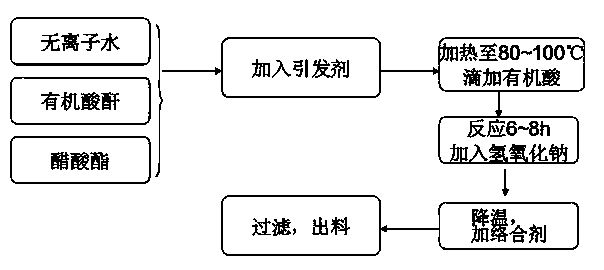

[0014] see figure 1 , A preparation method of calcium, strontium and barium scale inhibitor, adding 80-120kg of organic acid anhydride, 15-35kg of acetate, 150-250kg of deionized water into a 500L reactor, adding 0.5-1kg of initiator, and heating to 80-100℃, Add 30-80kg of organic acid dropwise, react for 6-8 hours; add 5-25kg of sodium hydroxide, cool to room temperature, add 50-100kg of complexing agent, stir for 30 minutes, and filter out.

[0015] The organic acid anhydride is one or a mixture of acetic anhydride, tartaric acid, citric acid, maleic anhydride, and phthalic anhydride.

[0016] Acetate is one or a mixture of ethyl acetate, methyl acetate, propyl acetate, or vinyl acetate.

[0017] The initiator is one or two of benzoyl peroxide, ammonium persulfate, or azobisisobutyronitrile.

[0018] The organic acid is one or a mixture of acrylic acid or methacrylic acid or styrene sulfonic acid or epoxysuccinic acid or aspartic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com