Preparation method of biomass source N/P co-doped carbon aerogel/cross-linked chitosan composite membrane electrode

A technology of cross-linked chitosan and carbon airgel, which is applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of relying on the fine structure and size of templates, difficulty in mass production, and high production costs. Achieve the effect of reducing production cost, increasing adsorption capacity and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 (by chitosan and N, P co-doped carbon airgel mass ratio is 1:0.1 implementation)

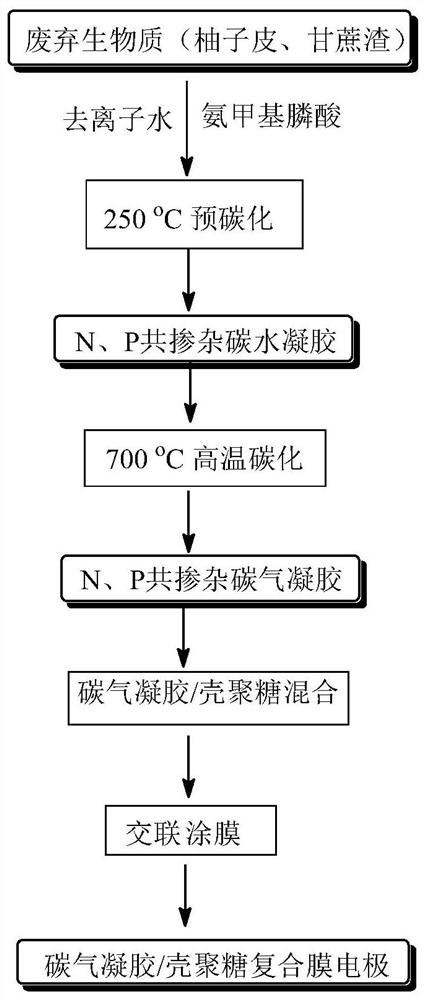

[0030] The preparation method of biomass source N, P co-doped carbon airgel / cross-linked chitosan composite membrane electrode, the specific steps are as follows:

[0031] (1) Preparation of biomass-sourced N and P co-doped carbon aerogels

[0032] The discarded biomass (grapefruit peel, bagasse) is removed from the outer skin, cut into a suitable size and washed, and then the 30g biomass is fully absorbed, then mixed with 80ml deionized water, 3g aminomethylphosphonic acid (N, P co-doping sources) were added to the hydrothermal kettle together, and the hydrothermal reaction was carried out at 250°C for 16 hours to obtain pre-carbonized N and P co-doped carbon hydrogels, and then the pre-carbonized N and P co-doped The carbon hydrogel is soaked in a mixture of water and ethanol for several days to remove soluble impurities in the pre-carbonized N, P co-doped carbon hydrogel;

...

Embodiment 2

[0037] Example 2 (by chitosan and N, P co-doped carbon airgel mass ratio is 1:0.2 implementation)

[0038] The preparation method of biomass source N, P co-doped carbon airgel / cross-linked chitosan composite membrane electrode, the specific steps are as follows:

[0039] (1) Preparation of biomass-sourced N and P co-doped carbon aerogels

[0040] The discarded biomass (grapefruit peel, bagasse) is removed from the outer skin, cut into a suitable size and washed, and then the 30g biomass is fully absorbed, then mixed with 80ml deionized water, 3g aminomethylphosphonic acid (N, P co-doping sources) were added to the hydrothermal kettle together, and the hydrothermal reaction was carried out at 250°C for 16 hours to obtain pre-carbonized N and P co-doped carbon hydrogels, and then the pre-carbonized N and P co-doped The carbon hydrogel is soaked in a mixture of water and ethanol for several days to remove soluble impurities in the pre-carbonized N, P co-doped carbon hydrogel;

...

Embodiment 3

[0045] Example 3 (by chitosan and N, P co-doped carbon airgel mass ratio is 1:0.3 implementation)

[0046] The preparation method of biomass source N, P co-doped carbon airgel / cross-linked chitosan composite membrane electrode, the specific steps are as follows:

[0047] (1) Preparation of biomass-sourced N and P co-doped carbon aerogels

[0048] The discarded biomass (grapefruit peel, bagasse) is removed from the outer skin, cut into a suitable size and washed, and then the 30g biomass is fully absorbed, then mixed with 80ml deionized water, 3g aminomethylphosphonic acid (N, P co-doping sources) were added to the hydrothermal kettle together, and the hydrothermal reaction was carried out at 250°C for 16 hours to obtain pre-carbonized N and P co-doped carbon hydrogels, and then the pre-carbonized N and P co-doped The carbon hydrogel is soaked in a mixture of water and ethanol for several days to remove soluble impurities in the pre-carbonized N, P co-doped carbon hydrogel;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com