Environment-friendly preparation method of polyamide microspheres

A polyamide and environment-friendly technology, applied in the field of environment-friendly preparation of polyamide microspheres, can solve problems such as unfavorable environmental protection, chemical danger, increase of preparation cost, etc., and achieves avoiding cost increase, good particle size consistency, and avoiding process Complicated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

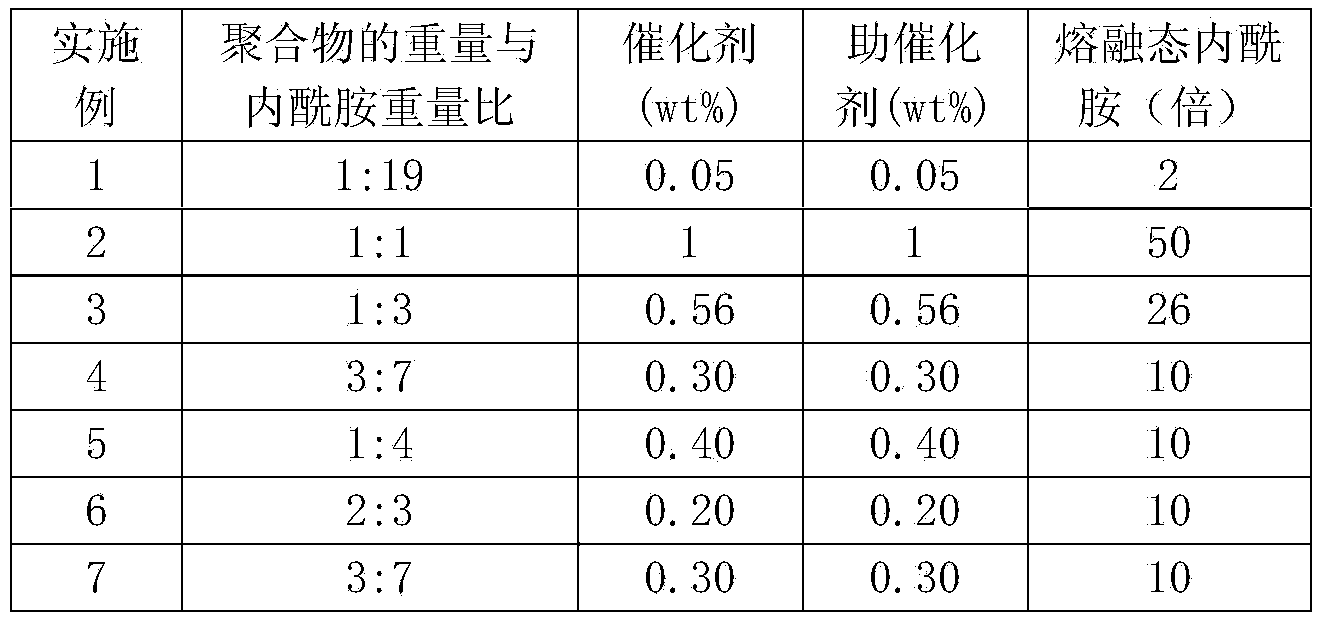

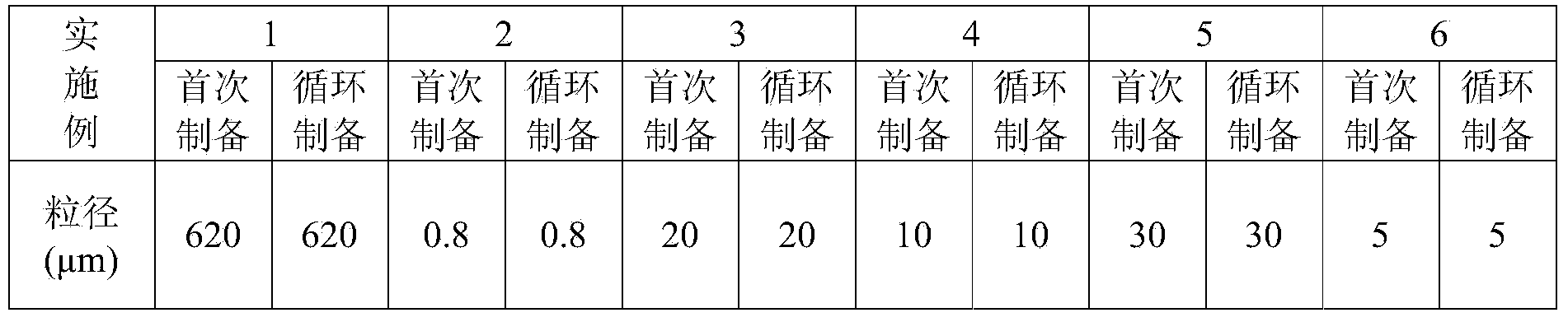

Embodiment 1

[0021] Weigh 95g of butyrolactam, heat it to a molten state of 30°C, add 5g of polystyrene into it, stir and dissolve; after the polystyrene is completely dissolved, turn on the vacuum pump, and carry out vacuum distillation on the above melt mixture to remove trace amounts of water, then add 0.05g of sodium and 0.05g of toluene-2,4-diisocyanate, mix quickly and evenly, pour it into a preheated mold at a temperature of 120°C, and carry out anionic ring-opening polymerization of butyrolactam, constant temperature reaction 1 Minutes later, the mold was cooled and demolded to obtain the polyamide / polystyrene alloy; the polyamide / polystyrene alloy was crushed, then added to 200g of molten butyrolactam at 30°C, fully dissolved and filtered, and the obtained insoluble matter was Polyamide microspheres; the remaining filtrate is the butyrolactam melt mixture containing 5g polystyrene, and the polystyrene of 5.27g is added in this melt mixture, and obtaining polystyrene content is the ...

Embodiment 2

[0023] Weigh 50g of caprolactam, heat it to 180°C to melt, then add 50g of polyacrylonitrile into it, and stir to dissolve; after the polyacrylonitrile is completely dissolved, turn on the vacuum pump, and carry out vacuum distillation on the above melt mixture to remove a small amount of water, and then Add 1g of sodium hydride and 1g of benzoyl chloride, mix quickly and evenly, pour into a preheated mold at a temperature of 180°C, carry out anionic ring-opening polymerization of caprolactam, react at a constant temperature for 30 minutes, and then cool and demould to obtain polyamide / polyethylene Acrylonitrile alloy. Break the polyamide / polyacrylonitrile alloy, then add it to 5000g of molten caprolactam at 180°C, fully dissolve and filter, the obtained insoluble matter is polyamide microspheres; the obtained filtrate is caprolactam containing 50g of polyacrylonitrile Melt mixture, add 4450g of polyacrylonitrile to the melt mixture to obtain a caprolactam melt mixture with a ...

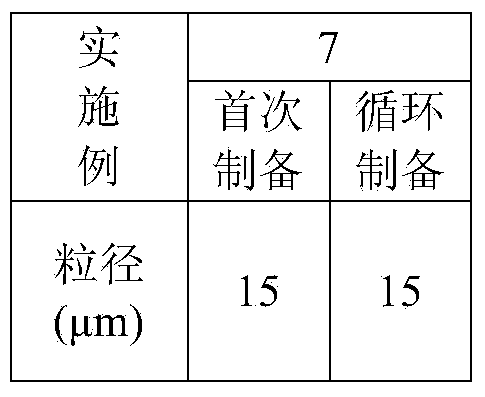

Embodiment 3

[0025] Weigh 75g of enantholactam, heat to 105°C to melt, then add 25g of polymethyl methacrylate, stir to dissolve; after the polymethyl methacrylate is completely dissolved, turn on the vacuum pump, and carry out vacuum distillation on the above melt mixture , remove a small amount of water, then add 0.56g sodium ethoxide and 0.56g maleic anhydride, mix quickly and evenly, pour into a preheated mold with a temperature of 150°C, and carry out enantholactam anionic ring-opening polymerization reaction, constant temperature reaction After 15 minutes, it was cooled and demolded to obtain a polyamide / polymethyl methacrylate alloy. Break the polyamide / polymethyl methacrylate alloy, then add it to 2600g of molten enantholactam at 105°C, fully dissolve and filter, the obtained insoluble matter is polyamide microspheres; the obtained filtrate contains 25g The enantholactam melt mixture of polymethyl methacrylate, add 840g polyacrylonitrile to this melt mixture, obtain the polyacrylon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com