Method for preparing Ce<3+>-activated scintillation glass in air atmosphere

A technology of flashing glass and air atmosphere, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of increasing the cost of glass preparation and increasing the complexity of glass preparation process, so as to simplify the preparation process and manufacturing cost, chemical The effect of easy adjustment of components and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation process

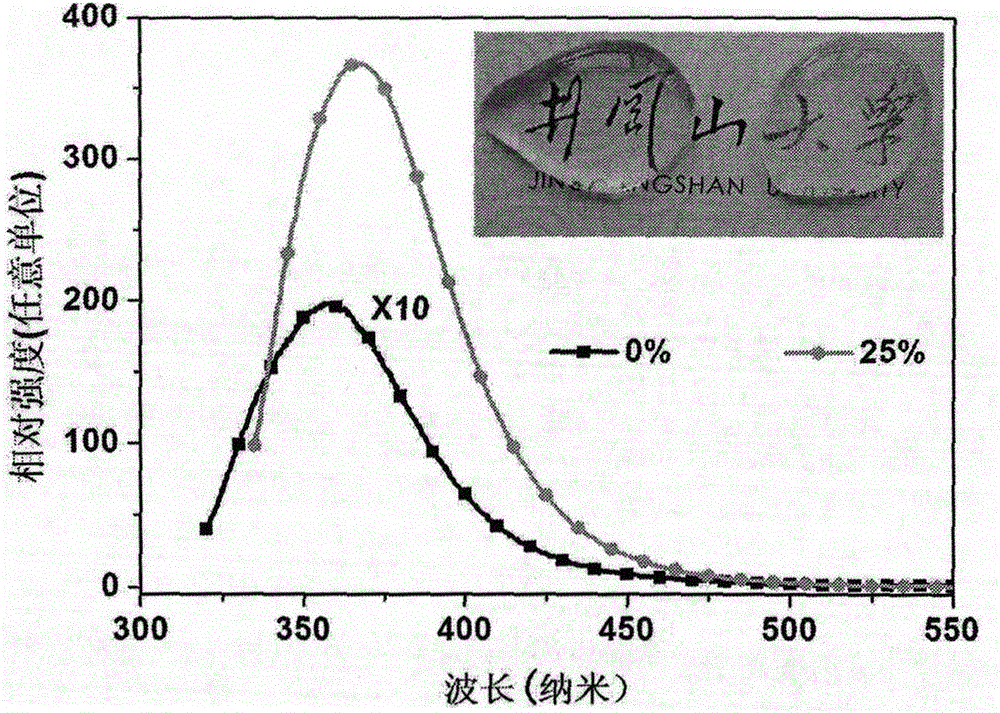

[0032] The first step: the borate scintillation glass formula of embodiment 1 is 32Li 2 O-64B 2 o 3 -4Gd 2 o 3 -0.25Ce 2 o 3 (X.Sun, et al., Nucl.Instrum.Meth.A, tosubmit), luminescent center Ce 3+ ions from CeO 2 introduce. In order to reflect the content of the patent of the present invention, undoped (0%) and externally doped 25% Si were prepared under the same conditions 3 N 4 (concentration in CeO 2 Concentration is reference, the same below) Two pieces of scintillation glass with strong reducing agent;

[0033] Step 2: Mix the formula thoroughly and melt it in the air atmosphere at 1000°C for 1 hour by high-temperature melting method;

[0034] Step 3: Pour the above melt into a preheated 300°C stainless steel mold for casting;

[0035] Step 4: Place the above glass in a muffle furnace at 370°C for 5 hours for annealing treatment, and then naturally cool to room temperature with the furnace to obtain the scintillation glass sam...

Embodiment 2

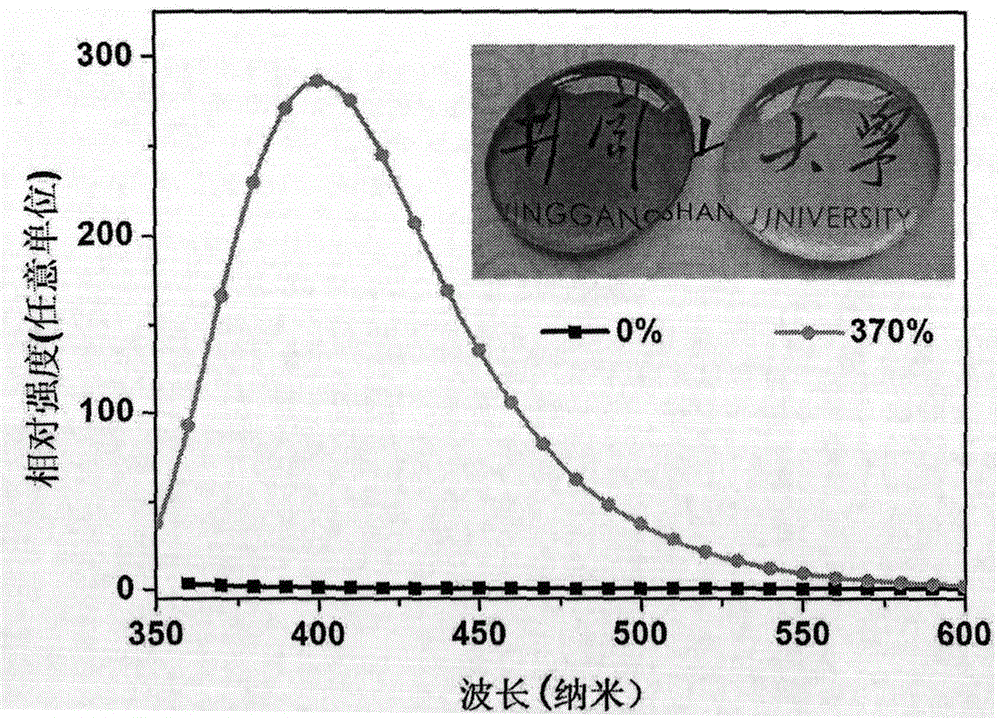

[0042] Embodiment 2 borosilicate scintillation glass component is 25B 2 o 3 -30SiO 2 -15BaO-29Gd 2 o 3 -1Ce 2 o 3 (Source of components: C.Jiang, P.Deng, J.Zhang, F.Gan, Phys.Lett.A323(2004)323-328), luminescent center Ce 3+ ions from CeO 2 introduce. In order to reflect the content of the patent of the present invention, undoped (0%) and externally doped 370% Si were prepared under the same conditions. 3 N 4 Two pieces of scintillating glass with strong reducing agent, the melting atmosphere is air, the melting temperature is 1470°C, the holding time is 3h, and the glass is annealed in a muffle furnace at 650°C for 12h after forming.

[0043] figure 2 Be the photoluminescence collection of collections (excitation wavelength 340nm) of embodiment 2 borosilicate scintillating glass, from figure 2 It can be seen that a broad peak located between 350-600 nm corresponds to the Ce 3+ The nanosecond optical transition of ions 5d-4f has the strongest emission peak near 4...

Embodiment 3

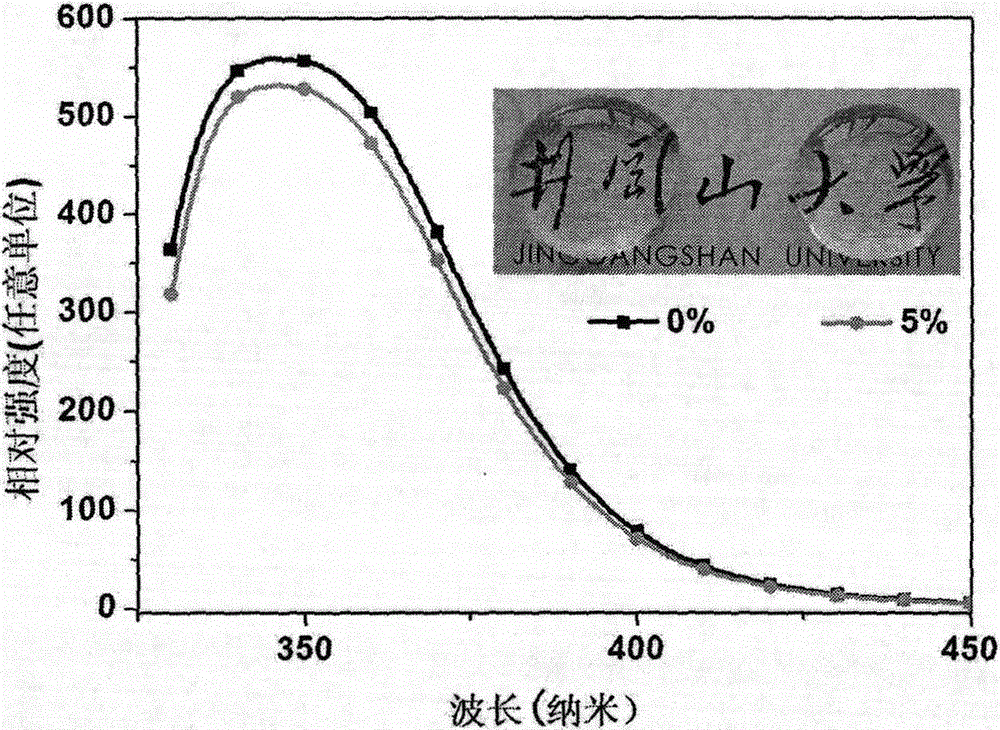

[0045] Embodiment 3 phosphate scintillation glass component is 80P 2 o 5 -10Na 2 O-10Gd 2 o 3 -0.6CeO 2 (Component sources: Zhong Jiuping, Zhou Jianbang, Yu Jianyong, Liang Hongbin, Su Qiang, Gong Bin, Liu Mingbiao, Liu Revolution, Lai Zhiyuan, Chinese invention patent, CN103319087A), luminescent center Ce 3+ ions from CeO 2 introduce. In order to reflect the patent content of the present invention, undoped (0%) and externally doped 5% Si were prepared under the same conditions 3 N 4 Strong reducing agent two pieces of scintillation glass, and specially CeO 2 The concentration is increased from 0.2mol% in the original patent to 0.6mol%, the melting atmosphere is air, the melting temperature is 1250°C, the holding time is 0.5h, and the glass is annealed in a 400°C muffle furnace for 4h after forming.

[0046] image 3 It is the photoluminescence spectrum (excitation wavelength 321nm) of the phosphate scintillation glass of Example 3. The broad peak between 330-450nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com