Efficient liquid fuel additive and liquid fuel with additive

A liquid fuel and additive technology, applied in the field of high-efficiency liquid fuel additives and liquid fuels, can solve the problems of methanol’s low calorific value, accelerated combustion speed, and high latent heat of methanol, and achieve high heat utilization rate, corrosion prevention, and large flame Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

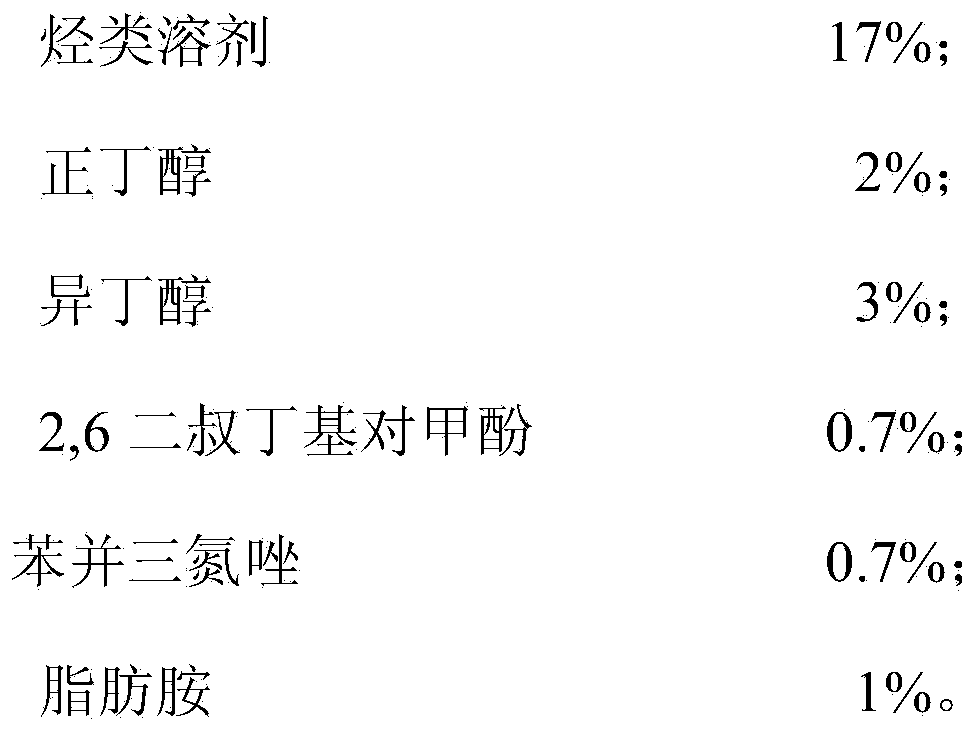

[0025] Embodiment 1: The liquid fuel additive provided by this embodiment on the one hand comprises the following components in weight percent:

[0026]

[0027]

[0028] The liquid fuel additive preparation method in the present embodiment is as follows:

[0029] Using the method of stirring while adding, add 2.4kg of MTBE, 3.2kg of acetone, 1kg of fatty amine, 2kg of n-butanol, 3kg of isobutanol, 0.7kg of 2,6-di-tert-butyl-p-cresol, and 0.7kg of benzotriazole Add 17kg of solvent hydrocarbons to fully dissolve and mix to form a uniform mixed solution. After mixing for 30 minutes, add the mixed solution to 70kg of condensed aldehyde and stir. After 30 minutes, a liquid fuel additive is obtained.

[0030] In another aspect of this embodiment, the liquid fuel containing the above-mentioned liquid fuel additive comprises the following components in weight percentage:

[0031] Liquid fuel additives 15%;

[0032] 83% sulfur-free methanol with an accuracy of 96%;

[0033] I...

Embodiment 2

[0036] Embodiment 2: The liquid fuel additive provided by this embodiment on the one hand comprises the following components in weight percent:

[0037]

[0038]

[0039] The liquid fuel additive preparation method in the present embodiment is as follows:

[0040] Using the method of stirring while adding, add 2.6kg of MTBE, 3kg of acetone, 0.8kg of fatty amine, 2kg of n-butanol, 3kg of isobutanol, 0.8kg of 2,6-di-tert-butyl-p-cresol, and 0.8kg of benzotriazole Add 15kg of solvent hydrocarbon to fully dissolve and mix to form a uniform mixed solution. After mixing for 32 minutes, add the mixed solution to 72kg of condensed aldehyde and stir. After 30 minutes, a liquid fuel additive is obtained.

[0041] In another aspect of this embodiment, the liquid fuel containing the above-mentioned liquid fuel additive comprises the following components in weight percentage:

[0042] Liquid fuel additives 16.5%;

[0043] 81% sulfur-free methanol with an accuracy of 96%;

[0044] ...

Embodiment 3

[0047] Embodiment 3: The liquid fuel additive provided by this embodiment on the one hand comprises the following components in weight percent:

[0048]

[0049] The liquid fuel additive preparation method in the present embodiment is as follows:

[0050] Using the method of adding and stirring, add 2kg of MTBE, 2.5kg of acetone, 0.6kg of fatty amine, 3kg of n-butanol, 4kg of isobutanol, 0.4kg of 2,6-di-tert-butyl-p-cresol, and 0.5kg of benzotriazole 15.5kg of solvent hydrocarbons, fully dissolved and mixed to form a uniform mixed solution, mixed for 30 minutes, then added to 71.5kg of condensed aldehyde and stirred, and the liquid fuel additive was obtained after 30 minutes.

[0051] In another aspect of this embodiment, the liquid fuel containing the above-mentioned liquid fuel additive comprises the following components in weight percentage:

[0052] Liquid fuel additives 15%;

[0053] 82% sulfur-free methanol with an accuracy of 96%;

[0054] Industrial soft water 3%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com