Preparation of natural nutshell carbon material and application of natural nutshell carbon material in electrochemical capacitors

A nutshell carbon, natural technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of reducing the conductivity of carbon materials, restricting the specific gravity of carbon materials, and achieve good stability and stability. , the effect of increasing the specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: making porous nano pistachio shell carbon material

[0067] Step 1, carbonization of natural fruit shell;

[0068] Pistachio shells with a moisture content of less than 5% are placed in a steel jade boat in a tube furnace, and carbonized in a protective atmosphere of high-purity argon gas with a volume percentage of 99.99%, to obtain carbonized pistachio shells;

[0069] Carbonization conditions: raise the temperature to 270°C at a heating rate of 3°C / min, and treat at a constant temperature for 2 hours; then raise the temperature to 750°C at a heating rate of 3°C / min, and treat at a constant temperature for 3 hours;

[0070] In the present invention, the tube furnace is a 1200-degree open-type vacuum atmosphere tube furnace with multi-temperature zones produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., whose model is SX-G05123K-655.

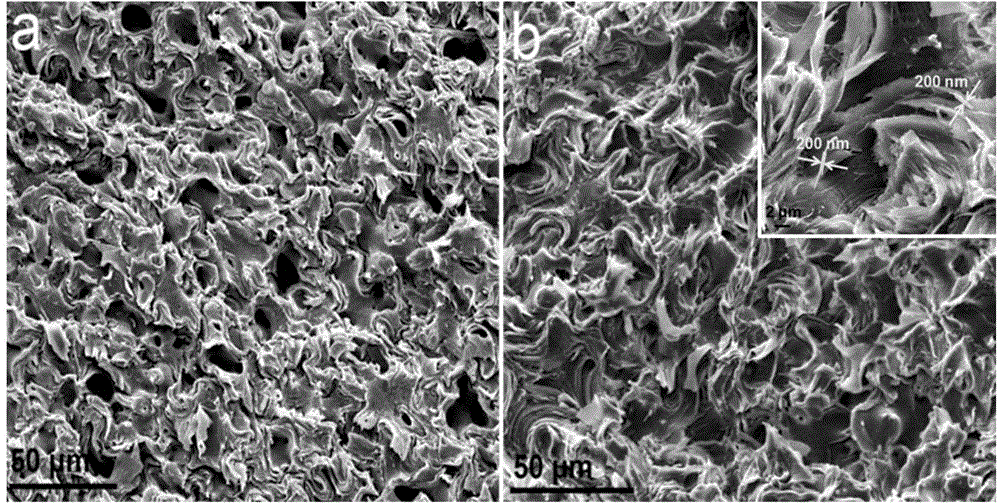

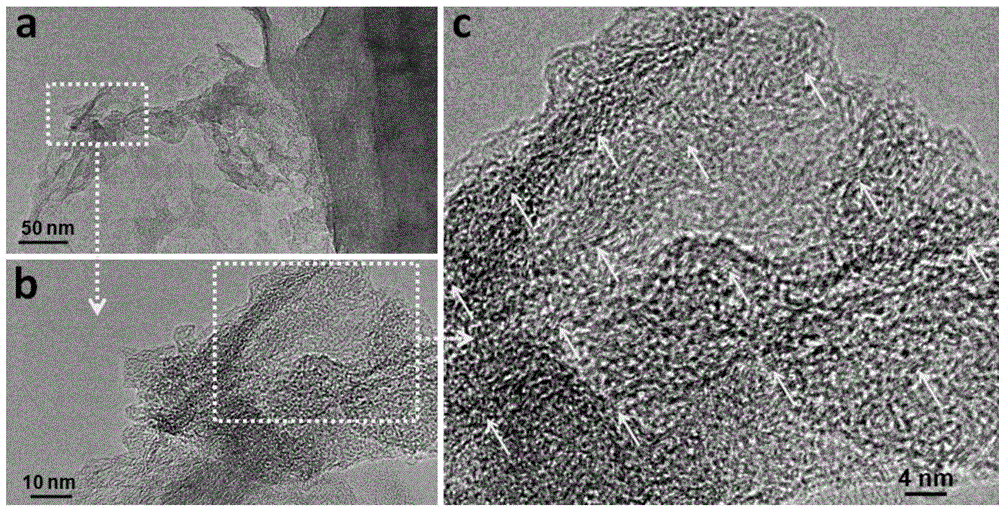

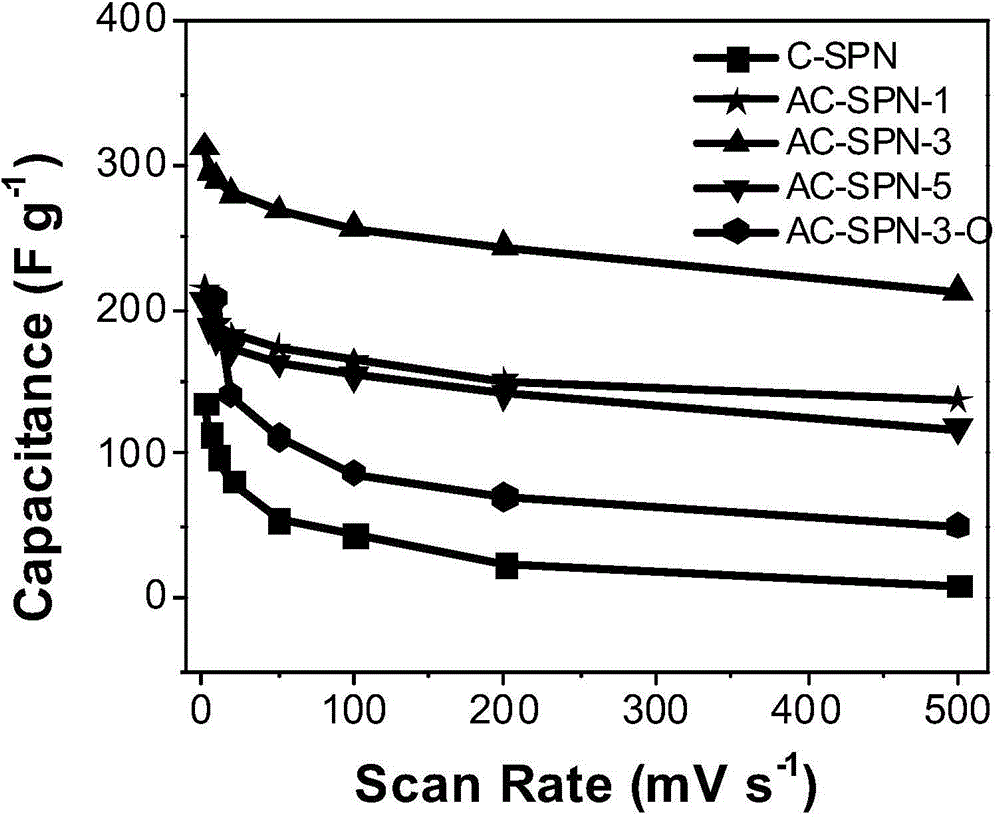

[0071] see figure 1 As shown, a in the figure is a scanning electron microscope (SEM) photo of pista...

Embodiment 2

[0103] Embodiment 2: making porous nano-peanut shell shell carbon material

[0104] Step 1, carbonization of natural fruit shell;

[0105] placing peanut shells with a moisture content of less than 5% in a steel jade boat in a tube furnace, and carbonizing them in a protective atmosphere of high-purity argon with a volume percentage of 99.99%, to obtain carbonized peanut shells;

[0106] Carbonization conditions: raise the temperature to 220°C at a heating rate of 5°C / min, and treat at a constant temperature for 1 hour; then raise the temperature to 750°C at a heating rate of 3°C / min, and treat at a constant temperature for 3 hours;

[0107] In the present invention, the tube furnace is a 1200-degree open-type vacuum atmosphere tube furnace with multi-temperature zones produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., whose model is SX-G05123K-655.

[0108] By observing the peanut shell shell under a scanning electron microscope (SEM), its surface morphol...

Embodiment 3

[0128] Embodiment 3: making porous nano walnut shell shell carbon material

[0129] Step 1, carbonization of natural fruit shell;

[0130] placing walnut shells with a water content of less than 5% in a steel jade boat in a tube furnace, and carbonizing them in a protective atmosphere of high-purity argon with a volume percentage of 99.99%, to obtain carbonized walnut shells;

[0131] Carbonization conditions: raise the temperature to 300°C at a heating rate of 10°C / min, and treat at a constant temperature for 3 hours; then raise the temperature to 800°C at a heating rate of 5°C / min, and treat at a constant temperature for 4.5 hours;

[0132] In the present invention, the tube furnace is a 1200-degree open-type vacuum atmosphere tube furnace with multi-temperature zones produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., whose model is SX-G05123K-655.

[0133] By observing the walnut shell shell under a scanning electron microscope (SEM), its surface morpho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com