Preparation method of oxidized graphite fluoride

A technology of fluorinated graphite and fluorine oxide, applied in the direction of graphite, etc., can solve the problems of fluorinated graphite, such as large size, complicated process, poor thermal stability, etc., and achieve the effect of improved stability, simple process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a method for preparing surface functionalized oxidized graphite fluoride, the main steps of which are as follows:

[0054] 1) reflux pretreatment of fluorinated graphite raw materials;

[0055] 2) ultrasonic treatment is carried out to described graphite fluoride solution;

[0056] 3) suction filtration and drying of the graphite fluoride solution to obtain graphite fluoride with exposed carbon atoms on the edge of the preliminary intermediate;

[0057] 4) Oxidative modification of graphite fluoride with exposed carbon atoms at the edge;

[0058] 5) Suction filtration and drying to obtain the final product graphite fluoride oxide.

[0059] In step 1), the commercial fluorinated graphite is placed in a specific reagent to reflux, and the specific reagent is isopropanol (IPA) or tetrahydrofuran (THF); reflux process parameters: temperature 90°C, time 1-10h.

[0060] In step 2), the fluorinated graphite solution in step 1) is irradiated with power...

Embodiment 1

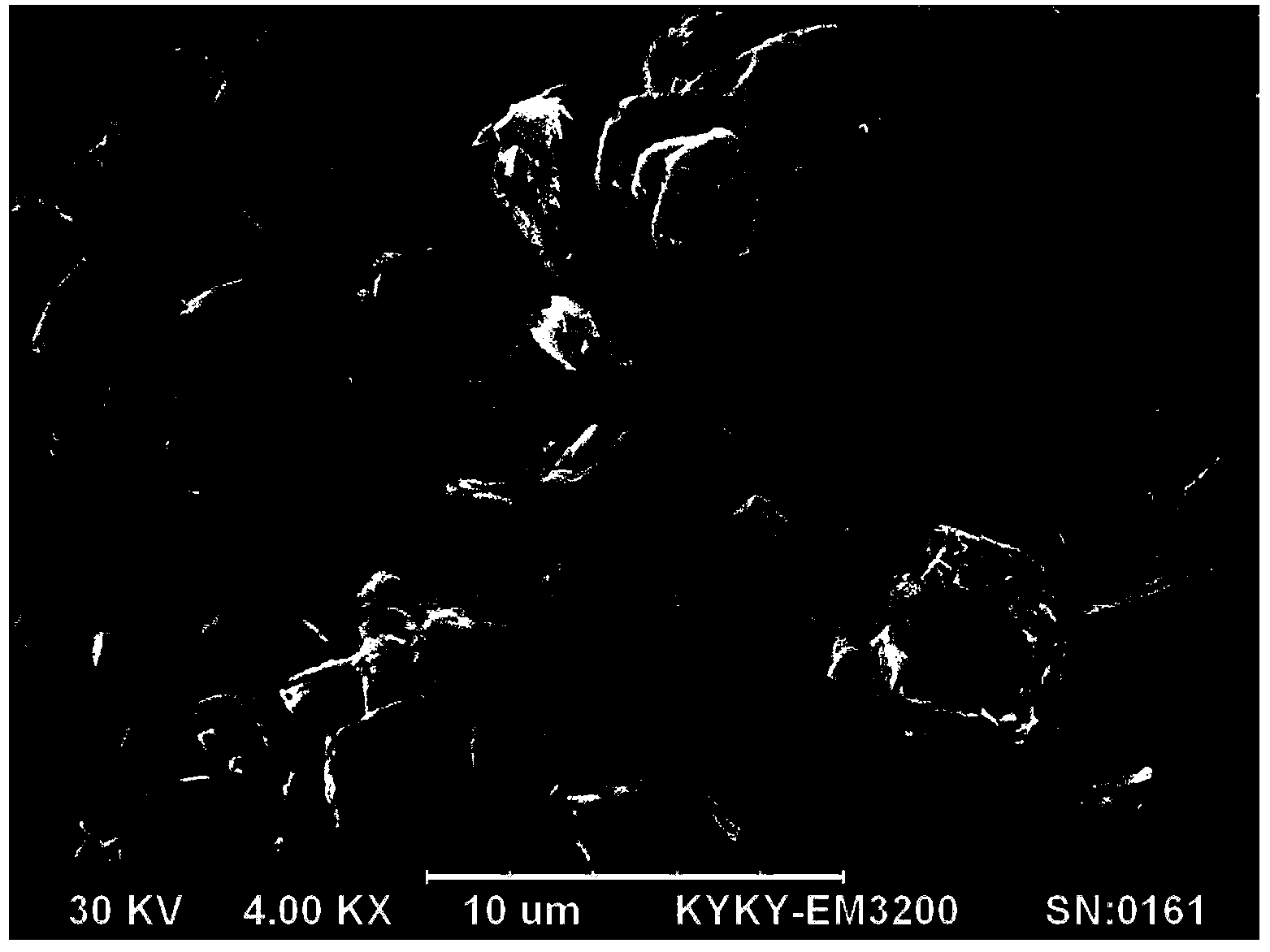

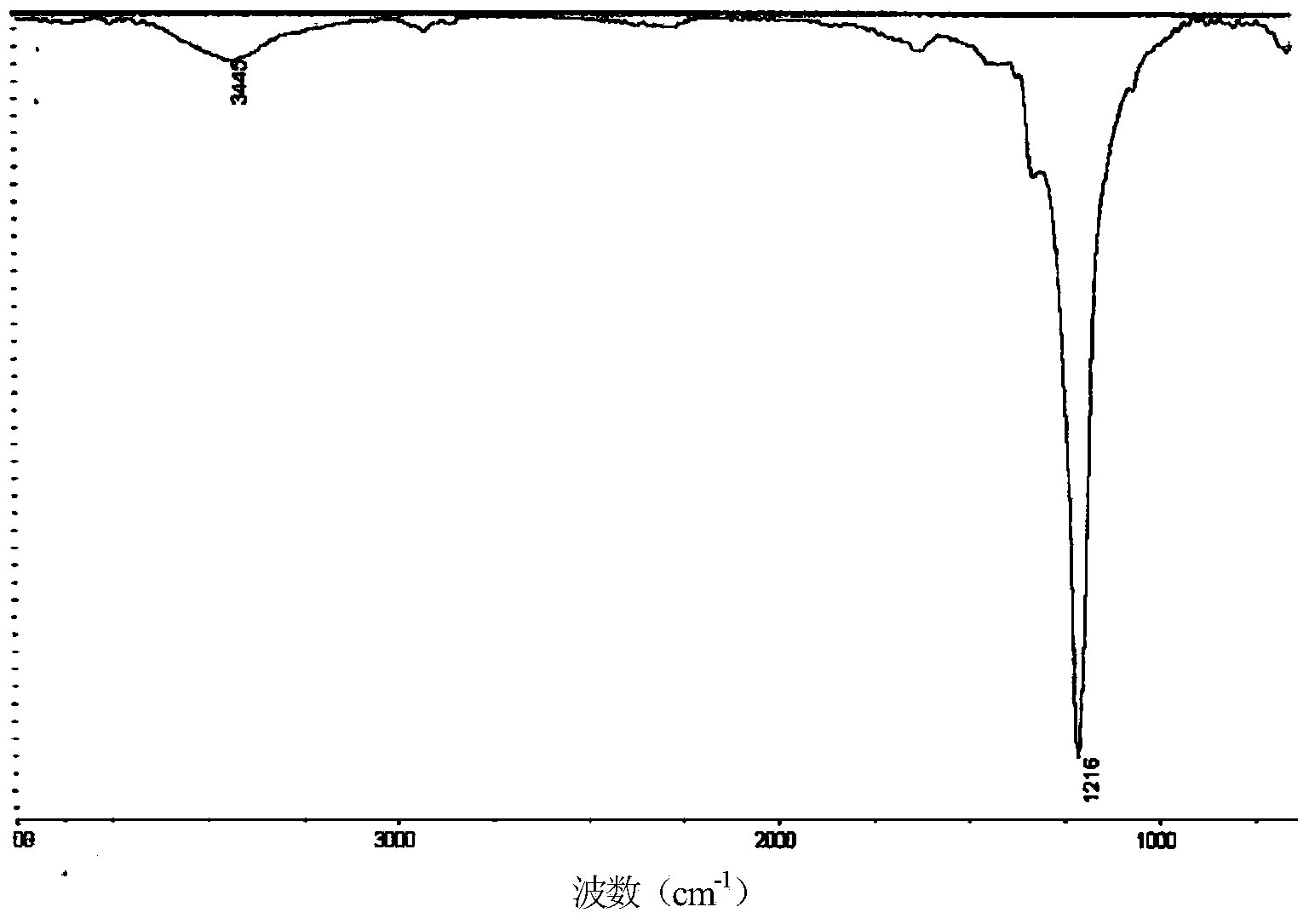

[0066] 10g graphite fluoride [ Picture 1-1 , Figure 1-2 , Figure 5-1 】Reflux in 300ml isopropanol at 90°C for 1 hour; irradiate with ultrasound at a frequency of 40kHz, output power 1.5KW, duty ratio 1:0.5, and power for 8 hours to obtain a fluorinated graphite solution with reduced size and exposed carbon atoms at the edge; Suction filtration and drying to obtain fluorinated graphite with exposed carbon atoms on the edge; oxidation by the improved Hummers method, adding 5g of sodium nitrate and 230g of concentrated sulfuric acid and mixing evenly, stirring slowly and adding 45g of KMnO 4 , kept at 0°C for 4h, moved to a water bath at 35°C for 30 minutes, gradually added 460ml of deionized water, and continued to react for 3h after the temperature rose to 98°C, diluted with water, and diluted with 30wt% H 2 o 2 Solution neutralization treatment (unreacted KMnO 4 ), fully washed with deionized water at 40°C, and dried in vacuum at 60°C for 48 hours to obtain "graphite flu...

Embodiment 2

[0071] 1g graphite fluoride 【 Picture 1-1 , Figure 1-2 , Figure 5-1 】Put in 100ml tetrahydrofuran and reflux at 90°C for 2h; irradiate ultrasonically at a frequency of 20kHz, output power 1KW, duty ratio 1:2, and power for 6h to obtain a fluorinated graphite solution with reduced size and exposed carbon atoms at the edge; suction filtration, Dry to obtain fluorinated graphite with exposed carbon atoms on the edge; oxidize using the improved Hummers method, add 0.5g sodium nitrate, 23g concentrated sulfuric acid and mix well, stir and slowly add 9g KMnO 4 , kept at 0°C for 2h, moved to a 35°C water bath for 30 minutes, gradually added 46ml of deionized water, and continued to react for 2h after the temperature rose to 98°C, diluted with water, and used 30wt% H 2 o 2 Solution neutralization treatment (unreacted KMnO 4 ), fully washed with deionized water at 40°C, and dried in vacuum at 50°C for 48 hours to obtain "graphite fluoride oxide [ Figure 2-2 , Figure 3-3 , F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com