Iodomethane preparation method and acetic acid production method

A technology of methyl iodide and acetic acid, which is applied in the field of preparation of methyl iodide, can solve problems such as the reduction of carbonylation reaction rate, and achieve the effects of constant dosage, saving equipment costs, and maintaining the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment is used to illustrate the production method of acetic acid provided by the invention.

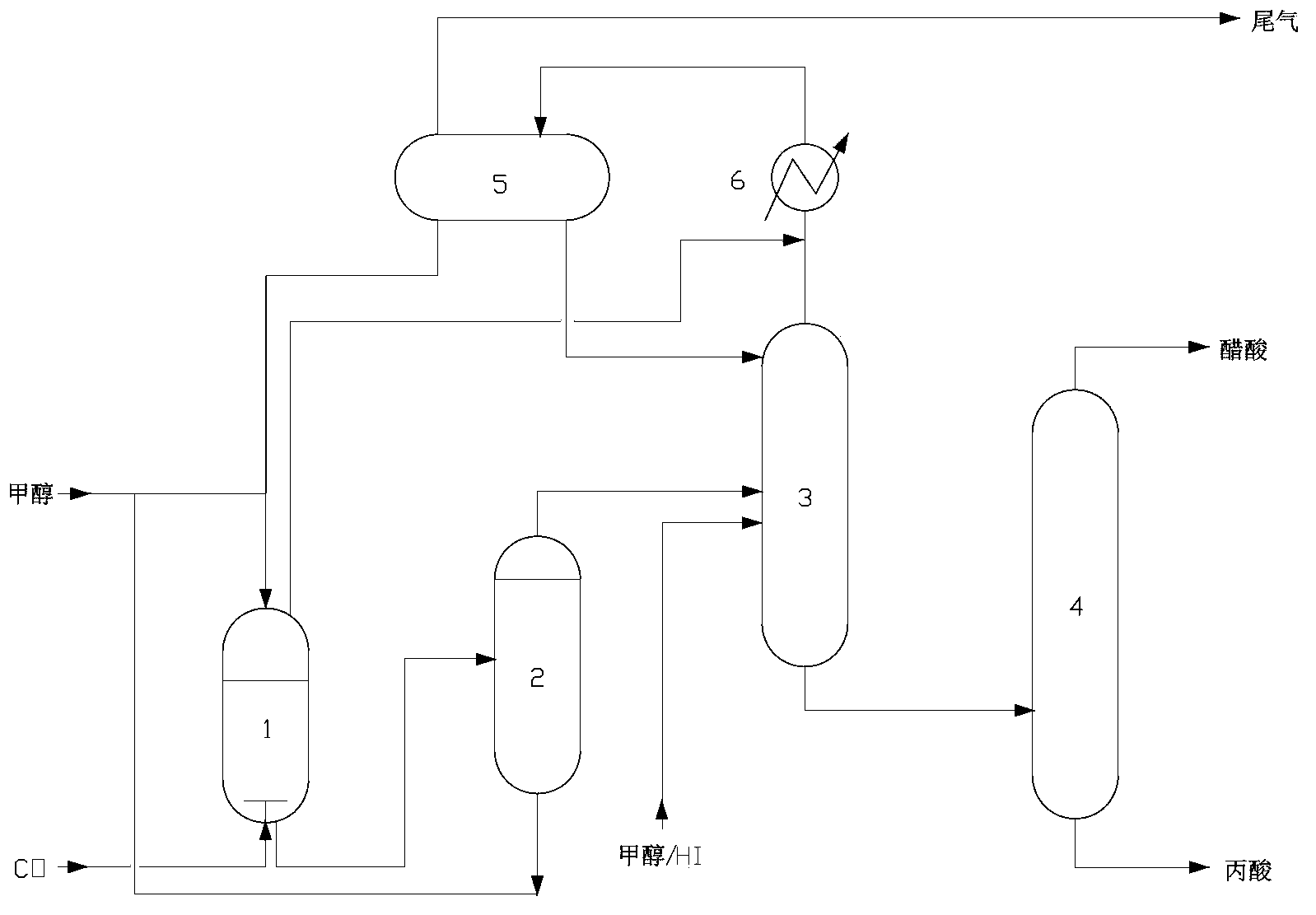

[0062] according to figure 1 The acetic acid production process flow chart shown carries out acetic acid production. The light components rectification column is simulated by a packed column with 60 theoretical plates.

[0063] Methanol with a material flow rate of 2457g / h and CO of 2408g / h are continuously fed into the 5L zirconium material reactor 1, and the Rh containing 200 wtppm, the Ir of 2000 wtppm, the Ru of 2000 wtppm, 8% by weight iodomethane, 5% by weight of water, 12% by weight of methyl acetate, and all the other being 528g of acetic acid reaction solution (the volume of the reaction solution is 4L) into the reactor 1 to carry out the carbonylation reaction, the temperature of the reaction is 190 °C, and the reaction pressure is 3.0 MPa. The mixture obtained after the reaction is sent to the flash tower 2 for flash evaporation to obtain a gas phase com...

Embodiment 2

[0071] This embodiment is used to illustrate the production method of acetic acid provided by the invention.

[0072] according to figure 1 The acetic acid production process flow chart shown carries out acetic acid production. A packed column with 40 theoretical plates was used to simulate the distillation column.

[0073] The methanol and the CO of 2311g / h that material flow rate is 2316g / h are continuously sent in the 5L zirconium material reactor 1, and the Rh that contains 200 wtppm, the Ir of 1500 wtppm, the Ru of 1500 wtppm, 9 wt% iodomethane, 5.5% by weight of water, 12% by weight of methyl acetate, all the other being 528g of acetic acid reaction solution (the volume of the reaction solution is 4L) into the reactor 1 for carbonylation, the temperature of the reaction is 195 °C, the reaction pressure is 2.8MPa. The mixture obtained after the reaction is sent to the flash tower 2 for flash evaporation to obtain a gas phase component containing acetic acid and an acet...

Embodiment 3

[0081] This embodiment is used to illustrate the production method of acetic acid provided by the invention.

[0082] according to figure 1 The acetic acid production process flow chart shown carries out acetic acid production. The rectification column is simulated by a packed column with 50 theoretical plates.

[0083] The methanol and the CO of 2208g / h that material flow rate is 2253g / h are continuously sent in the 5L zirconium material reactor, and the Rh that contains 200 wtppm, the Ir of 2500 wtppm, the Ru of 1500 wtppm, the Ru of 7 wt% Iodomethane, the water of 4.5% by weight, the methyl acetate of 12% by weight, all the other are the reaction solution of 528 grams of acetic acid (the volume of reaction solution is 4L) and pass in the reactor 1 and carry out carbonylation reaction, the temperature of reaction is 185 °C, the reaction pressure is 3.2MPa. The mixture obtained after the reaction is sent to the flash tower 2 for flash evaporation to obtain the gas phase co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com