Iron-based carbon-containing pellets with waste plastic as carbon source and preparation method thereof

A technology of waste plastics and carbon pellets, which is applied in the field of metallurgical industry, can solve the problems of weakening the contact degree of waste plastics and iron-containing materials, the inability to realize the close accumulation of mixed materials, and the loss of the reduction function of waste plastics, so as to achieve full contact and excellent The effect of cold strength and increasing the reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

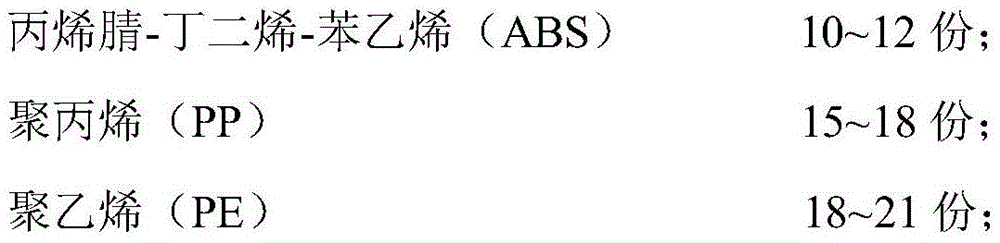

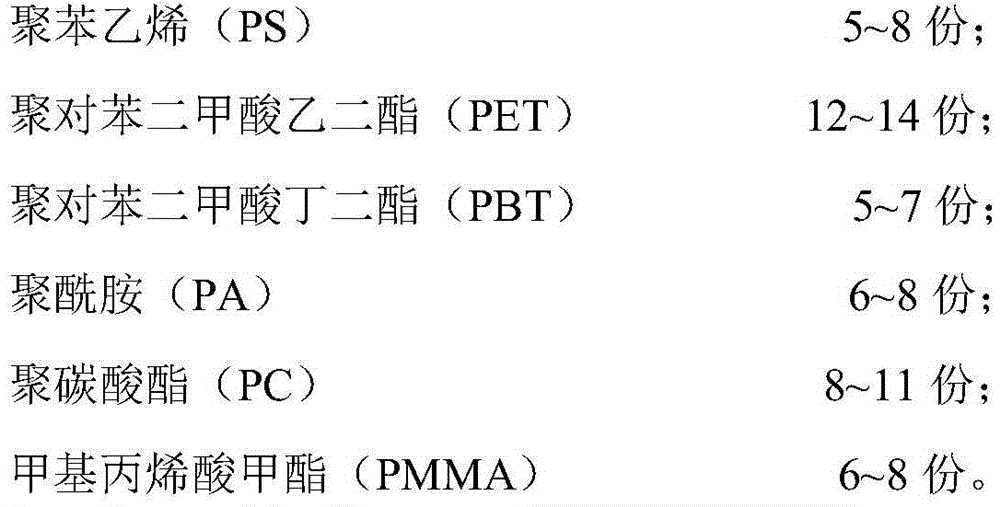

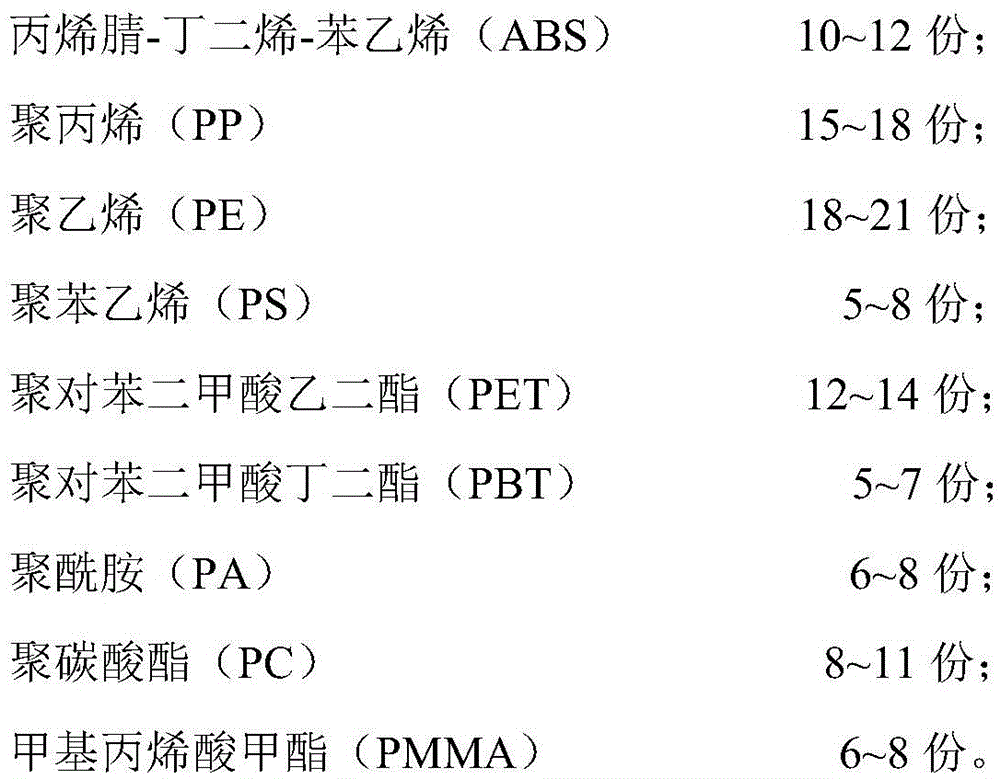

[0033] A waste plastic in this embodiment is an iron-based carbon-containing pellet of carbon source, which is composed of the following components in weight percentage: 83% of iron-based material and 17% of waste plastic. Among them: the mass of waste plastics whose particle size is less than 80 mesh accounts for 100% of the total mass of waste plastics, and waste plastics are composed of acrylonitrile-butadiene-styrene (ABS), polypropylene (PP), polyethylene (PE), polystyrene Polyethylene (PS), Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Polyamide (PA), Polycarbonate (PC) and Methyl Methacrylate (PMMA) Composition, the above-mentioned components are composed as follows in parts by mass: 11 parts of acrylonitrile-butadiene-styrene (ABS), 15 parts of polypropylene (PP), 18 parts of polyethylene (PE), 6 parts of polystyrene (PS) 13 parts of polyethylene terephthalate (PET), 6 parts of polybutylene terephthalate (PBT), 7 parts of polyamide (PA), 11 parts ...

Embodiment 2

[0044] One kind of waste plastics in this embodiment is iron-based carbon-containing pellets of carbon source, which is composed of the following components in weight percentage: 70% of iron-based materials and 30% of waste plastics. Among them: the mass of waste plastics whose particle size is less than 80 mesh accounts for 98% of the total mass of waste plastics, and waste plastics are composed of acrylonitrile-butadiene-styrene (ABS), polypropylene (PP), polyethylene (PE), polystyrene Polyethylene (PS), Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Polyamide (PA), Polycarbonate (PC) and Methyl Methacrylate (PMMA) Composition, the above-mentioned components are composed as follows in parts by mass: 10 parts of acrylonitrile-butadiene-styrene (ABS), 16 parts of polypropylene (PP), 20 parts of polyethylene (PE), 5 parts of polystyrene (PS) 12 parts of polyethylene terephthalate (PET), 5 parts of polybutylene terephthalate (PBT), 6 parts of polyamide (PA),...

Embodiment 3

[0054] A waste plastic in this embodiment is an iron-based carbon-containing pellet of carbon source, which is composed of the following components in weight percentage: 85% of iron-based material and 15% of waste plastic. Among them: the mass of waste plastics whose particle size is less than 80 mesh accounts for 96% of the total mass of waste plastics, and waste plastics are composed of acrylonitrile-butadiene-styrene (ABS), polypropylene (PP), polyethylene (PE), polystyrene Polyethylene (PS), Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Polyamide (PA), Polycarbonate (PC) and Methyl Methacrylate (PMMA) Composition, the above-mentioned components are composed as follows in parts by mass: 12 parts of acrylonitrile-butadiene-styrene (ABS), 15 parts of polypropylene (PP), 20 parts of polyethylene (PE), 8 parts of polystyrene (PS) 12 parts of polyethylene terephthalate (PET), 5 parts of polybutylene terephthalate (PBT), 6 parts of polyamide (PA), 8 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com