Method for bundling, wrapping and ensiling whole-plant corn

A whole-plant corn, wrapping technology, applied in the preservation method of animal feed raw materials, climate change adaptation, animal feed, etc., can solve the problem of not being stored for too long, affecting grass, etc., to enhance disease resistance and improve quality. , the effect of easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

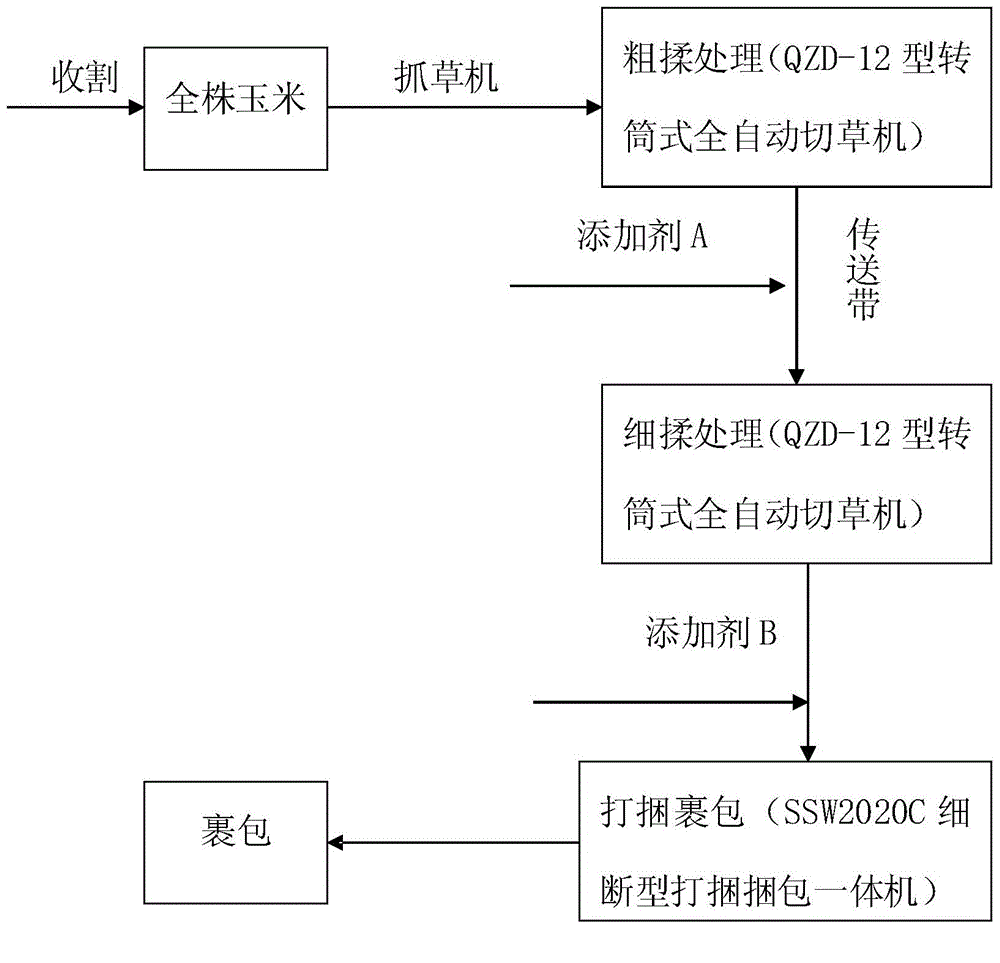

[0032] A method for whole-plant corn bundling and silage includes the following processing steps:

[0033] (1) Preparation of special silage additive for whole plant corn

[0034] ①Preparation of Additive A: Mix 3kg of Chinese medicine Codonopsis pilosula, 2kg of acanthopanax cortex and 2kg of Chinese angelica into a Chinese medicine composition, add 17.5kg of water, soak the liquid surface with Chinese medicine, place it at 4℃ for 24h, then extract at 70℃ for 30min, After filtering, add 17.5kg of water, extract at 80°C for 40min, filter again, mix the filtered liquid medicine twice, and concentrate to 7L at 75°C to obtain 1g / ml Chinese medicine liquid, and add selenium to it The content of 44% sodium selenite is 1.591g to make the selenium concentration reach 1mg / ml, stir it evenly, and store it at 4℃;

[0035] ②Preparation of additive B: mix 8 g of amylase, 25 g of cellulase, 3 g of pectinase, 5 g of xylanase, and 1 g of cellobiose dehydrogenase into mixed enzyme powder; 15 g of S...

Embodiment 2

[0048] A method for whole-plant corn bundling and silage includes the following processing steps:

[0049] (1) Preparation of special silage additive for whole plant corn

[0050] ①Preparation of additive A: Mix 6kg of Chinese medicine Codonopsis pilosula, 4kg of acanthopanax cortex, and 4kg of angelica to form a Chinese medicine composition, add 35kg of water, soak the liquid with Chinese medicine, place it at 4℃ for 24h, extract at 70℃ for 30min, filter Then, add 35kg of water, extract at 80℃ for 40min, filter again, mix the two filtered medicinal solutions, and concentrate to 14L at 75℃ to obtain 1g / ml Chinese medicinal solution, and add selenium to it. 3.1815g of 44% sodium selenite to make the concentration of selenium reach 1mg / ml, stir evenly, seal, and store at 10℃;

[0051] ②Preparation of additive B: mix 15 g of amylase, 30 g of cellulase, 5 g of pectinase, 8 g of xylanase, and 3 g of cellobiose dehydrogenase into mixed enzyme powder; 10 g of Streptococcus thermophilus and...

experiment example

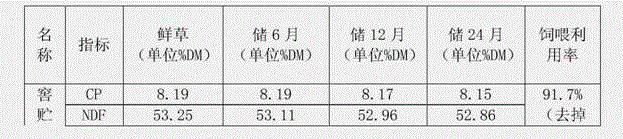

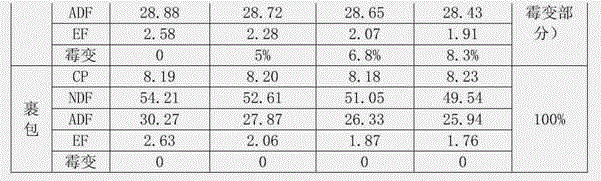

[0064] Comparing the whole-plant corn fodder wrapped in silage processed in Example 1 with ordinary pit storage fodder, the CP value, NDF value, ADF value, EF value and mildew degree of each storage period were determined.

[0065] Experimental measurement data records, as shown in the following table:

[0066]

[0067]

[0068] Experimental results: By comparing the whole plant corn cellar storage and bundling treatment, it can be seen that its composition can be basically kept unchanged within 24 months after wrapping, and the NDF and ADF values have decreased significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com