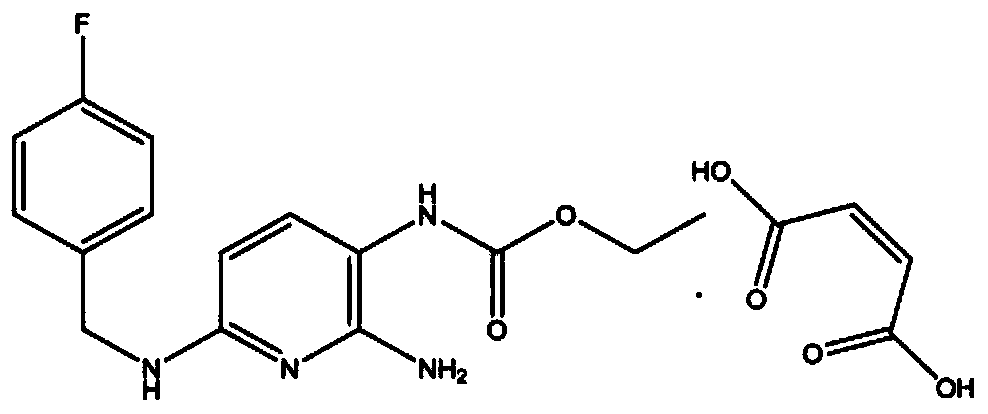

Flupirtine maleate capsule composition and preparation method thereof

A technology of flupirtine maleate capsules and flupirtine maleate, which is applied in the field of flupirtine maleate capsule composition and its preparation, and can solve problems such as uneven mixing of raw and auxiliary materials, high production cost, and low bulk density , to achieve the effect of large-scale production, qualified product quality and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

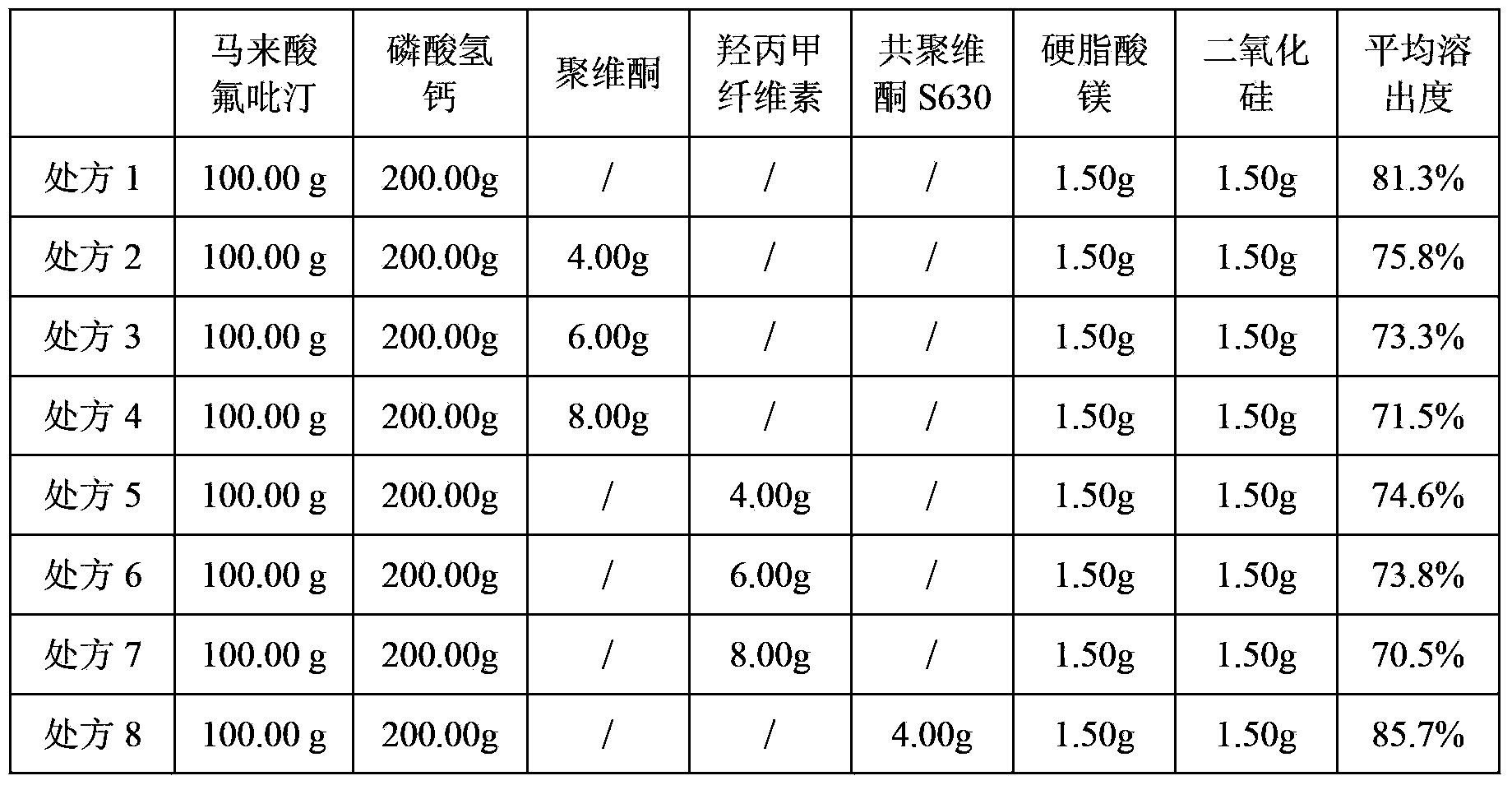

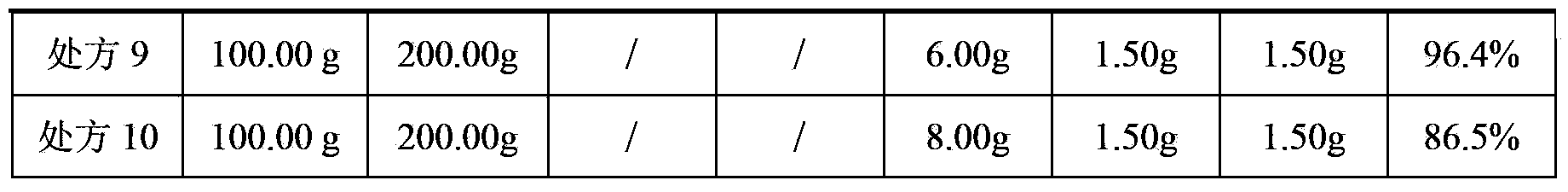

Examples

Embodiment 1

[0066] Preparation Process:

[0067] (1) Screening of ingredients: Weigh the flupirtine maleate raw material and calcium hydrogen phosphate in the prescribed amount, pre-mix for 10 minutes, pass the mixed material through a 60-mesh sieve, and set aside;

[0068] (2) Mixing: add the prescribed amount of copovidone S630 to step (1), and mix for about 30 minutes;

[0069] (3) Granulation: granulation by dry granulation;

[0070] (4) Total blending: Add the prescribed amount of silicon dioxide and magnesium stearate to the granules prepared in step (3), and mix for 5 minutes;

[0071] (5) Intermediate product inspection: calculate the content of mixed particles after total blending;

[0072] (6) Calculate the loading range, fill the capsules, and use polyvinyl chloride solid pharmaceutical hard tablets and aluminum foil for pharmaceutical packaging as inner packaging materials for packaging.

Embodiment 2

[0074] Preparation process: same as the preparation process of Example 1, the mixing time in step (2) is 25 minutes.

Embodiment 3

[0076] Preparation process: same as the preparation process of Example 1, the mixing time in step (2) is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com