Fluorine-containing biphenyl acetylene liquid crystal compound and preparation method thereof

A liquid crystal compound and phenylacetylene technology, which is applied in the fields of liquid crystal optical devices, liquid crystal displays, and fluorine-containing biphenylacetylene liquid crystal compounds, can solve the problems of difficulty in forming a eutectic liquid crystal mixture, high melting point, and inability to meet application requirements in low temperature performance. , to achieve the effect of high birefringence, low melting point and large dielectric anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

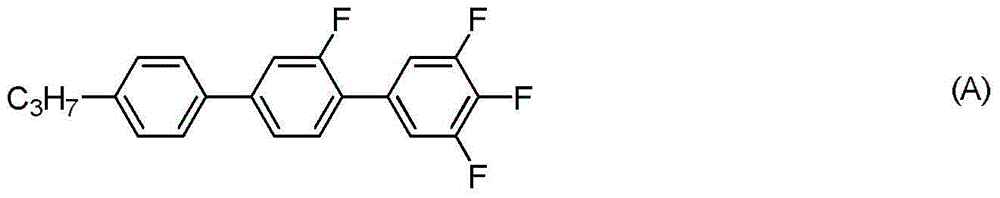

[0063] Preparation of 2,3',4',5'-tetrafluoro-4-((4-propylphenyl)ethynyl)biphenyl:

[0064] The specific structural formula is as follows:

[0065]

[0066] The preparation process is as follows:

[0067] (1) 30.1g (0.1mol) 3-fluoro-4-bromoiodobenzene, 100ml THF (not dried), 0.7g (0.001mol) bis(triphenylphosphine) palladium chloride, 0.57g (0.003mol) iodine Cuprous sulfide and 20.2g (0.2mol) of triethylamine were sequentially added to a 500ml three-necked flask, the air was replaced by high-purity nitrogen, and the temperature was lowered to 5°C. Dissolve 14.4g of 4-propylphenylacetylene in 100ml of THF, add dropwise to the reaction flask, and complete the drop within 1hr. After dripping, the temperature was naturally raised to room temperature and reacted for 5 hours. The by-product salt was removed by filtration, the filtrate was evaporated to dryness, and the obtained oily product was dissolved through a silica gel column with n-heptane. The resulting solution was concentrated ...

Embodiment 2~ Embodiment 6

[0079] Use 4-ethylphenylacetylene, 4-butylphenylacetylene, 4-pentylphenylacetylene, 4-hexylphenylacetylene, 4-heptylphenylacetylene to replace 4-propylphenylacetylene in Example 1, respectively, the same The method synthesizes:

[0080] 2,3',4',5'-tetrafluoro-4-((4-ethylphenyl)ethynyl)biphenyl;

[0081] 2,3',4',5'-tetrafluoro-4-((4-butylphenyl)ethynyl)biphenyl;

[0082] 2,3',4',5'-tetrafluoro-4-((4-pentylphenyl)ethynyl)biphenyl;

[0083] 2,3',4',5'-tetrafluoro-4-((4-hexylphenyl)ethynyl)biphenyl;

[0084] 2,3',4',5'-tetrafluoro-4-((4-heptylphenyl)ethynyl)biphenyl.

Embodiment 7

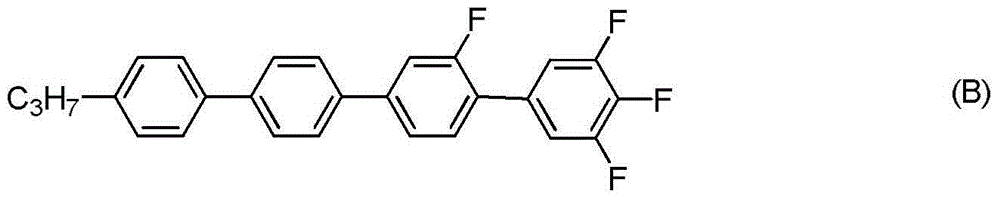

[0086] The preparation of 2,3',4'-trifluoro-4-((4-propylphenyl)ethynyl)biphenyl, the specific structural formula is as follows:

[0087]

[0088] Using 3,4-difluorophenylboronic acid instead of 3,4,5-trifluorophenylboronic acid in Example 1, 2,3',4'-trifluoro-4-(( 4-propylphenyl)ethynyl)biphenyl, the yield is 64%.

[0089] The liquid crystal phase transition temperature of 2,3',4'-trifluoro-4-((4-propylphenyl)ethynyl)biphenyl was tested by DSC at a temperature of 5℃ / min. The result is: C59.5N118 .4I.

[0090] Dissolve it in the basic formula at a mass ratio of 15% to test its refractive index, and extrapolate to obtain the birefringence Δn=0.3173, Δε=13.10, γ at 25°C and 589nm 1 = 109.8mPa·s. The compound has the advantages of high birefringence, large dielectric anisotropy, and low rotational viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com